EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

TROUBLESHOOTING Troubleshooting 63

Confidential

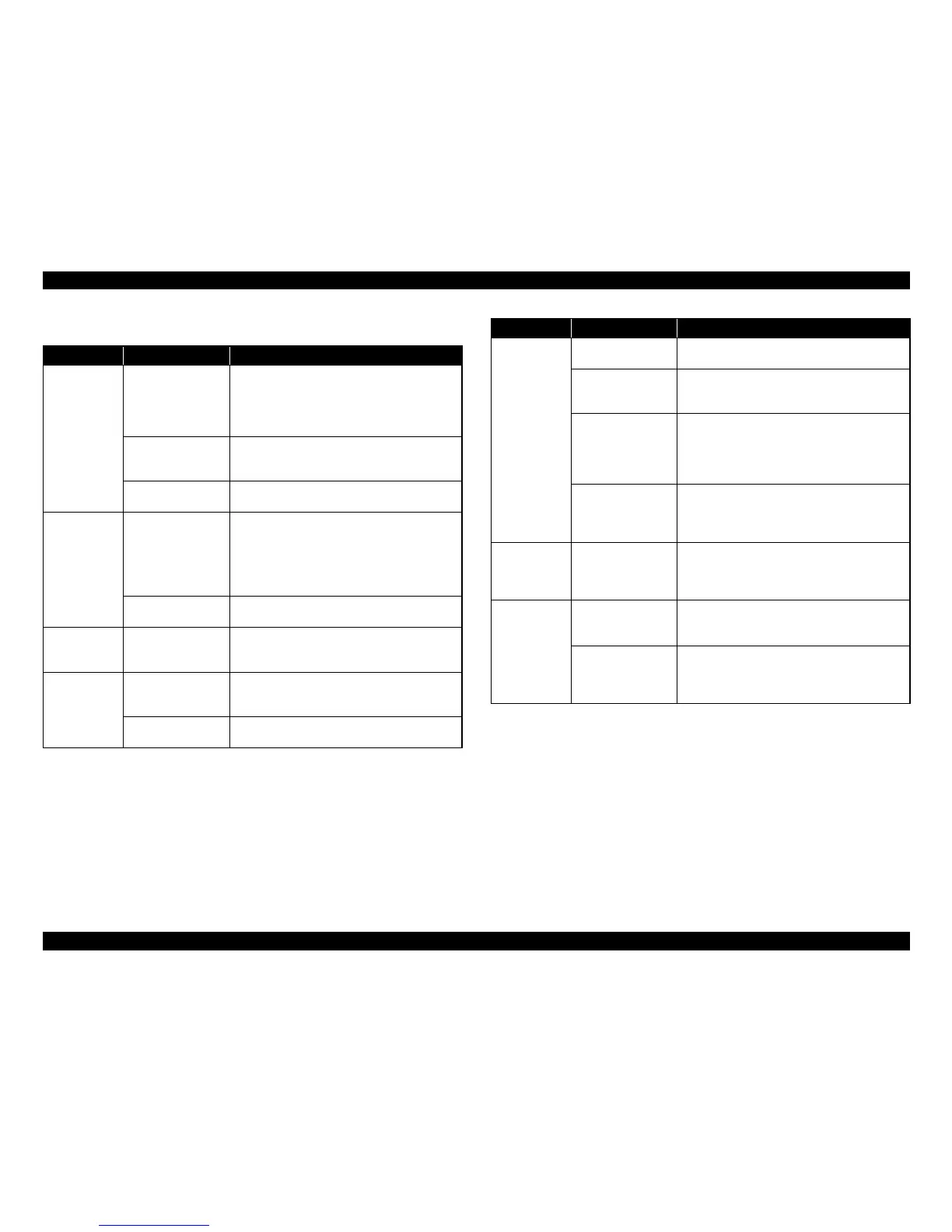

3.4.6 Mechanical Problems

Problem Possible cause Remedy

No primary

paper feed.

The paper feed roller

surface is

contaminated with

paper dust or other

foreign matter.

Clean the roller surface using isopropyl alcohol.

(See P. 152)

The paper feed roller

has become deformed.

Visually check the paper feed roller for deformation.

Replace the roller if deformation is observed. (See

P. 126)

Mounting failure of the

paper feed clutch.

Visually check the paper feed clutch. If the clutch is

not properly installed, fix it.

No secondary

paper feed.

The upper or/and

lower registration

rollers surface is

contaminated with

paper dust or other

foreign matter.

Clean the roller surface using isopropyl alcohol.

(See P. 152)

Mounting failure of the

registration clutch.

Visually check the registration clutch. If the clutch is

not properly installed, fix it.

Skewed paper

feed.

The paper guide inside

the cassette is not

properly adjusted.

Check if the paper guide is properly adjusted or

installed. If not, adjust the position or replace the

paper guide.

Multiple sheets

of paper are fed

at one time.

The separation roller

or the separation pad is

worn out.

If the roller or the pad is worn out, replace it. (See

P. 126)

The paper has become

curled.

If the paper has become curled, replace the paper.

Paper jams. The paper has become

curled.

If the paper has become curled, replace the paper.

Poor contact between

the upper and lower

registration rollers.

If the two rollers do not properly contact with each

other, fix it.

The heat roller or the

pressure roller is

extremely

contaminated, or has

become deformed.

Replace the fuser unit. (See P. 106)

Poor contact between

the paper eject roller

and the fuser paper

eject pulley.

If the roller and the pulley do not properly contact

with each other, fix it.

Toner drops on

the paper

conveying path.

The developing unit or

the photoconductor

unit is extremely

contaminated.

Clean the developing unit or the photoconductor

unit.

Abnormal noise

is heard.

The rollers, roller

bearings, and gears do

not rotate smoothly.

If any obstacles are found, remove them.

Apply grease to the bearings and gears if their

surface is dry.

Mounting failure of the

paper feed clutch,

registration clutch, or

developing clutch.

If any abnormality is found, fix it.

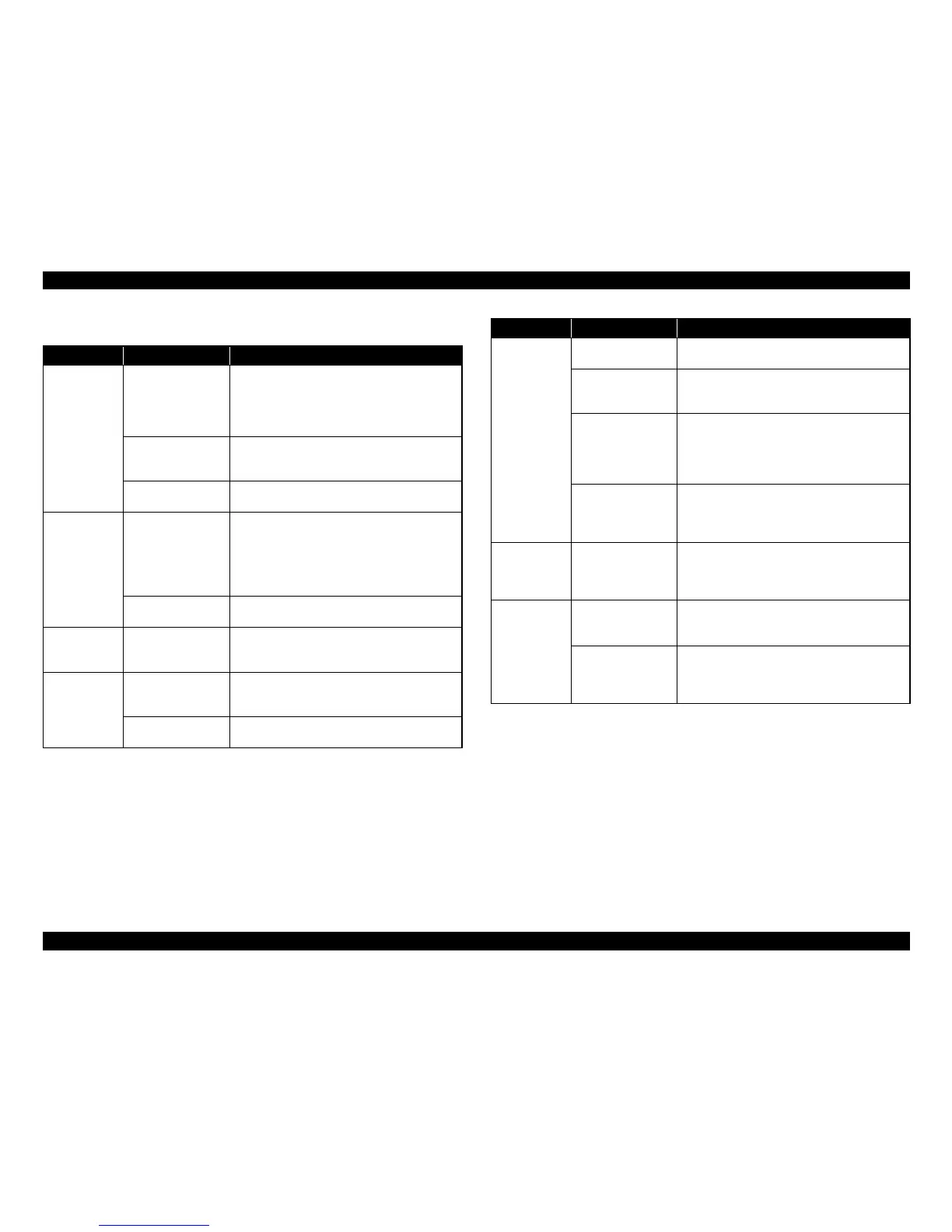

Problem Possible cause Remedy

Loading...

Loading...