Service Manual_AVA1_ENG-20220922_I 259

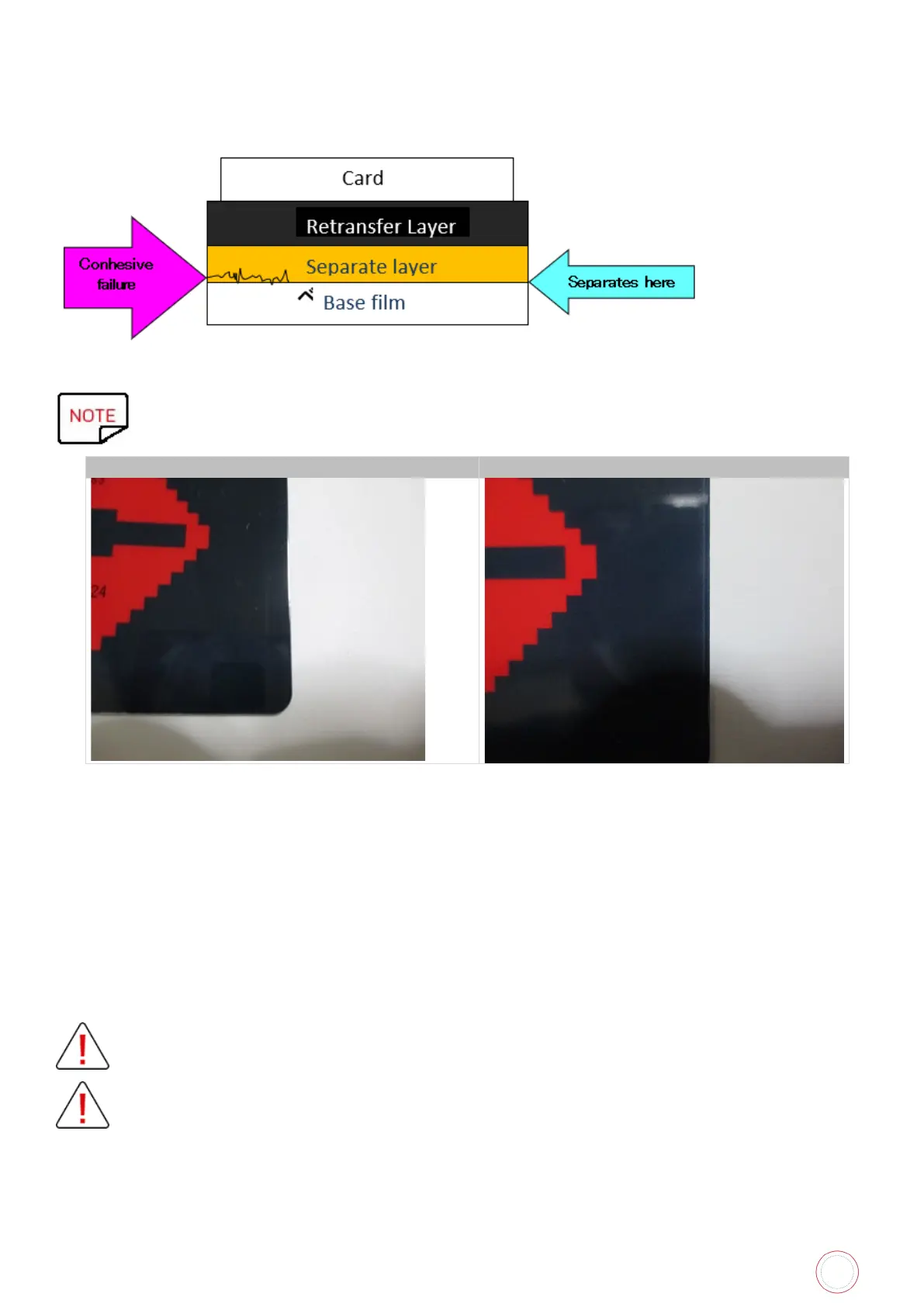

This issue occurs during secondary transfer when separate layer separates from base film.

Sometimes cohesive failure happens under some conditions like high density image (primary transfer

heat alters RT film structure), wrong transferring temperature, card material.

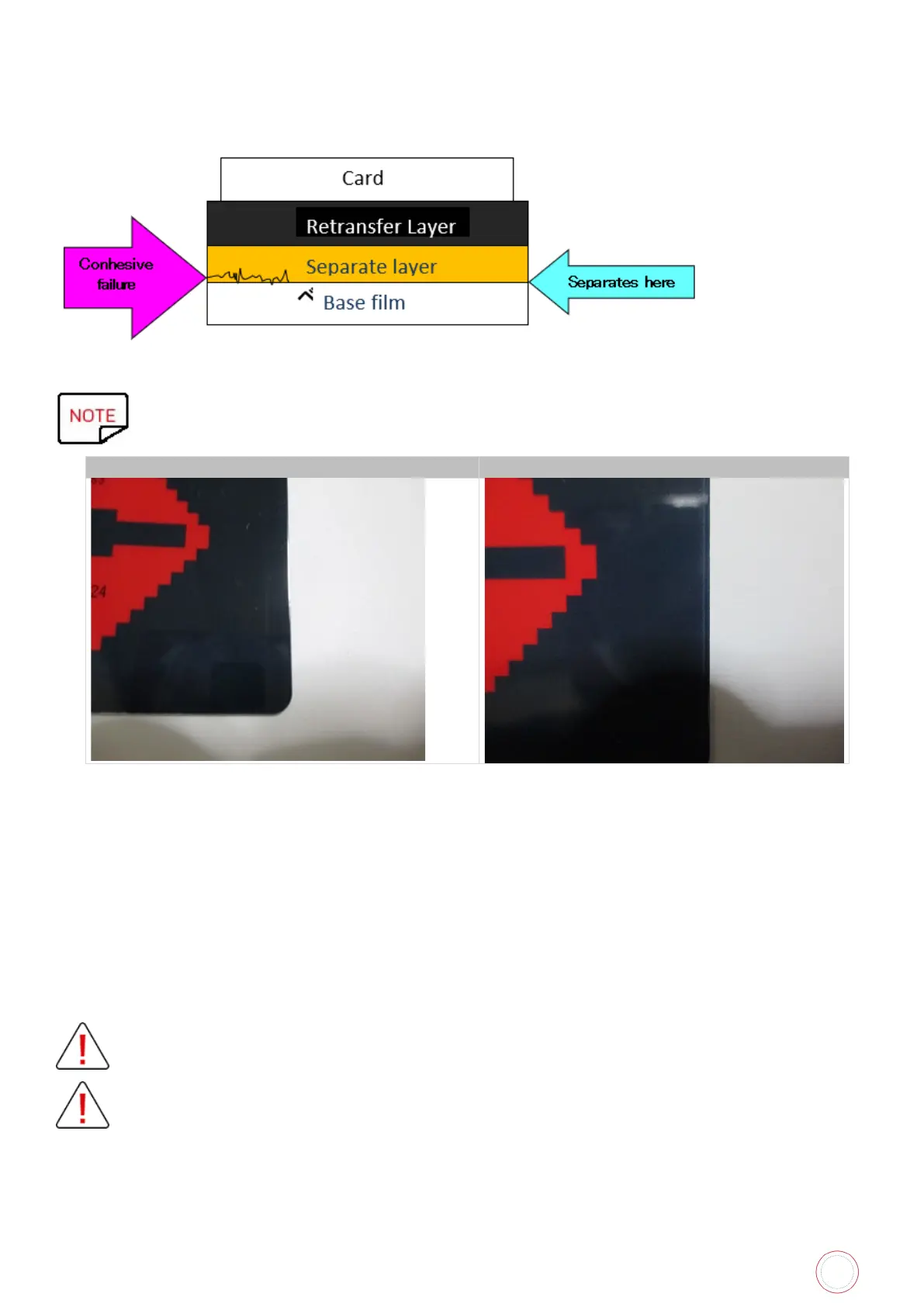

This cohesive failure part looks matte (or whitish) and should not be confused with edge line,

check below an example of Rubbing mark vs. Edge line:

Solution: Setting lower density for primary transfer or setting secondary transfer temperature higher.

1. Setting color density at primary transfer lower

Service mode>>Adjustment>>Density>>Adj Density YMC>>Set

2. Setting secondary transfer temperature higher

User mode>>card Setup>>Card Type1>>Card1(25, +8)

Card1(25, +8) is same setting as Card type PVC and which heat roller heat is 185 degrees.

Ex: Starting from Card1(25, +10) and increasing temperature step by step.

By making transportation speed slow, lamination time would be longer and has an effect on

secondary transfer problem.

Both rising transfer temperature and making transportation speed slow have an effect on card

curling. It may require setting decurl accordingly.

Loading...

Loading...