What to do if EXFO Test Equipment is not responding?

- DDarrell WilsonAug 5, 2025

If your EXFO Test Equipment is not responding, shut down the unit by pressing and holding the power button. Then, turn the unit on again to reset it.

What to do if EXFO Test Equipment is not responding?

If your EXFO Test Equipment is not responding, shut down the unit by pressing and holding the power button. Then, turn the unit on again to reset it.

What to do if EXFO Test Equipment battery status LED is red?

If the battery status LED on your EXFO Test Equipment is red, it may indicate that the battery temperature is too high. Shut down the unit by pressing and holding the power button for more than 10 seconds, or until the power LED goes off. It could also mean that the battery is defective. In this case, wait for the unit to cool down, and then reboot it. If the problem persists, contact EXFO or consider replacing the battery.

Why EXFO Test Equipment battery does not charge?

If your EXFO Test Equipment battery isn't charging as expected, it could be due to a high temperature. Ensure the temperature is within the specified operating range. Also, check if the battery is correctly connected.

Provides the full text of the EU declaration of conformity available at a specific internet address.

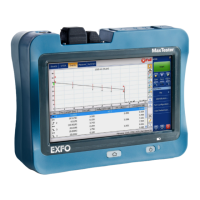

Lists key features like Broadcom chipset, IP login, DSL testing, and rugged design.

Describes typical uses such as Automatic Pair Quality Test, Multimeter tests, Noise tests, and fault location.

Details the physical interfaces and IP54 rating of the MaxTester device.

Explains the various connectors on the MaxTester device, including Ethernet, DSL, and ground terminals.

Directs users to the EXFO website for detailed technical specifications of the product.

Explains the meaning of WARNING, CAUTION, and IMPORTANT indicators used throughout the guide.

Provides critical warnings and cautions regarding the use of the AC/DC adapter and accessories.

Details operational parameters like temperature, humidity, altitude, and input power ratings for the unit.

Explains basic electrical symbols such as direct current and alternating current.

Explains how to power the unit on/off, the suspend mode, and shutdown procedures.

Describes navigation through menus using arrow keys and confirmation with the Enter key.

Illustrates and explains the function of each button on the MaxTester keypad.

Details how to take screenshots and access the device's online help function.

Introduces the main menu pane for navigating between different test applications and system settings.

Outlines the options for configuring unit parameters like display, date/time, and software.

Covers adjusting LCD brightness, language, and touchscreen calibration for optimal display.

Explains how to enable and select methods for uploading test results via Wi-Fi or Ethernet.

Presents the main menu for accessing copper qualification testing applications.

Details setting up software settings and cable values, saving parameters to profiles.

Allows configuration of parameters common to all tests, including Phone Book and Cable Book.

Manages groups of phone numbers relevant to copper tests, allowing add, clone, delete, load, and save functions.

Describes how to detect and control remote FED devices for automated testing, saving trips to the far end.

Lists the available multimeter tests, including Voltage, Current, and Resistance.

Explains how to detect AC/DC voltages and frequency, and measure voltage thresholds.

Covers measuring AC/DC currents and frequency, and setting AC/DC current thresholds.

Details measuring resistance values in ohms to identify shorts and grounds.

Describes running a resistance test over time to find high-resistive faults and measure pair insulation.

An intelligent test for quick pair quality assessment, identifying faults with plain language and color codes.

Provides a graphical snapshot to locate and identify line faults by analyzing results from multiple tests.

Introduces VF and WB noise measurements, and level measurements.

Measures unwanted energy in a loop from man-made and natural sources.

Measures Near End Crosstalk (NEXT) between cable pairs and the received crosstalk.

Covers VF and WB level measurements, signal strength reduction, and circuit balance.

Checks the VF longitudinal balance ratio to reduce common-mode voltage effects.

Calculates the dissipation of power of a transmitted signal over the copper line.

Measures signal power loss returned/reflected by a discontinuity in a transmission line.

Displays the line trace and updates results in real time for fault location.

Transmits on one pair and receives on another to detect and isolate split pairs.

Displays TDR test results, parameters, and graph analysis for reflections and distances.

Locates resistive faults between tip to ground, or ring to ground.

Allows viewing, uploading, exporting, and deleting saved RFL test results.

Provides access to automatic tests for pre-qualification, installation, and maintenance of circuit types.

Detects loop current and measures voice frequency parameters in copper telephone loops.

Runs a range of user-defined tests, comparing measured results against stored thresholds.

Navigates to DSL/IP test icons, connection summary, result manager, and test configuration.

Configures test parameters for Auto Test, Manual Test, and Ethernet Test applications.

Configures line and access modes, dependent on unit's Software Options and model.

Sets general settings and identification fields for DSL/IP tests.

Displays pass/fail status and details of test results, including Line Status and Operation Mode.

Allows viewing connection status between the WAN port and ISP, with various access methods.

Allows placing and receiving VoIP calls, displaying phone numbers, call status, and statistics.

Details how to save test results to internal memory or export reports via USB.

Covers viewing, uploading, exporting, and deleting saved DSL/IP test results.

Provides instructions for keeping the unit clean, dust-free, and storing it properly.

Explains battery operation, maximizing power, and handling replacement for Lithium Polymer batteries.

Presents common issues like unit not turning on or battery problems with their solutions.

Explains the meaning of different LED indicators for power, charging, and battery status.

Provides contact information for EXFO technical support, including phone numbers and email.

Outlines the one-year warranty against material and workmanship defects.

| Brand | EXFO |

|---|---|

| Model | MaxTester 635G |

| Category | Test Equipment |

| Language | English |