1-15-96 96-8100

11

TABLE OF CONTENTS

HAAS AUTOMATION, INC.

TROUBLESHOOTING

SERVICE

MANUAL

VF-SERIES

3.3 ACCURACY/BACKLASH

Accuracy complaints are usually related to tooling, programming, or fixturing problems. Eliminate these possibilities before

working on the machine.

´ Poor mill table-positioning accuracy.

l Check for a loose encoder on the servo motor. Also, ensure the key in the motor or the lead screw is in place and the

coupling is tight.

l Check for backlash in the lead screw as outlined below:

INITIAL PREPARATION -

Turn the VMC ON. ZERO RET the machine and move the mill table to the approximate center of its travel in the X and Y

directions. Move the spindle head to approximate center of the Z-axis travel, also.

CHECKING X-AXIS:

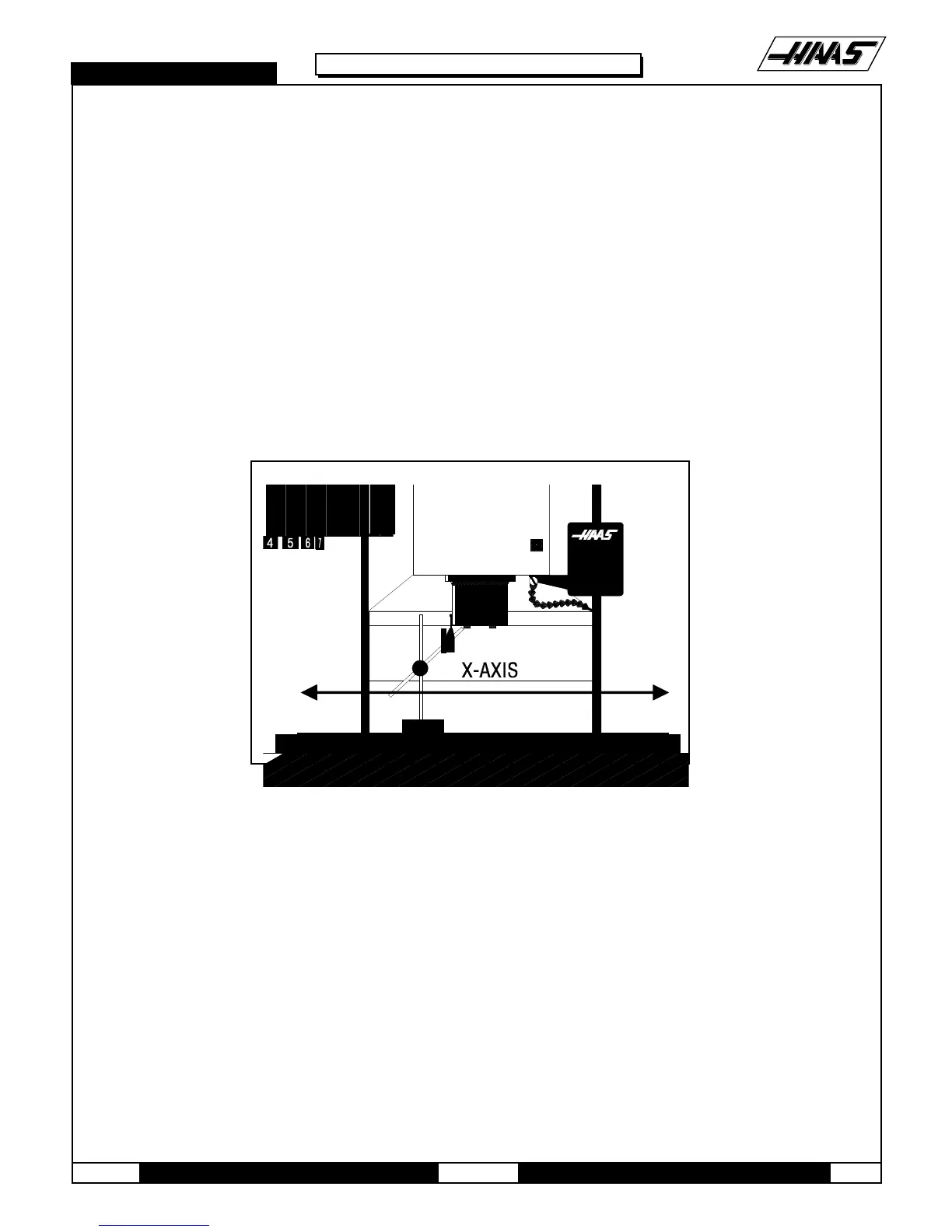

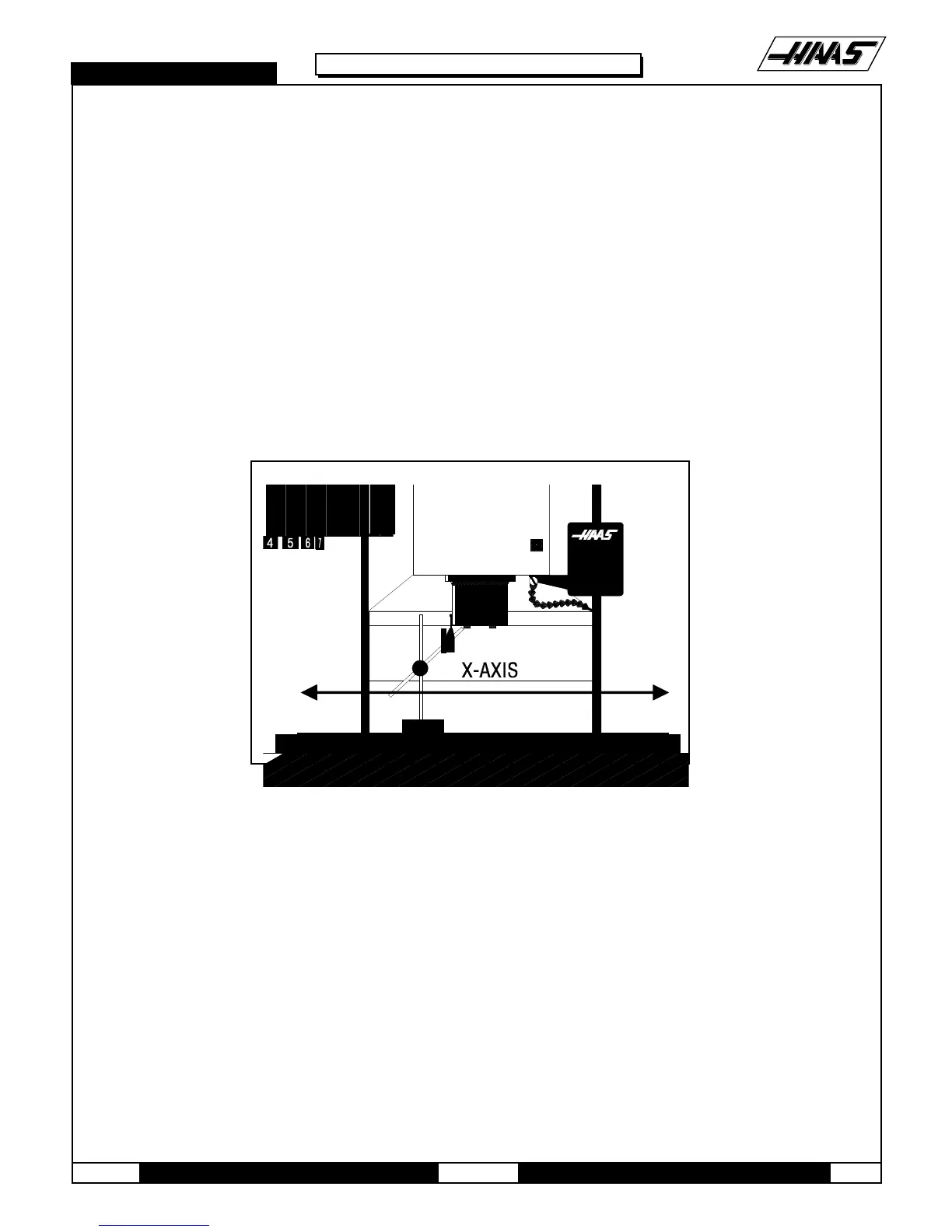

1. Set up a dial indicator and base on the mill table as shown in Fig. 3-1.

Fig. 3-1 Dial indicator in position to check X-axis.

2. Set dial indicator and the Distance to go display in the HANDLE JOG mode to zero as follows:

- Zero the dial indicator.

- Press the MDI button on the control panel.

- Press the HANDLE JOG button on the control panel.

The Distance to go display on the lower right hand corner should read: X=0 Y=0 Z=0

3. Set the rate of travel to .001 on the control panel and jog the machine .010 in the positive (+) X direction. Jog

back to zero (0) on the display. The dial indicator should read zero (0) ± .0001.

4. Repeat step three in the negative (-) direction.

TOTAL DEVIATION BETWEEN THE DIAL INDICATOR AND THE CONTROL PANEL DISPLAY SHOULD NOT EXCEED .0002.

Loading...

Loading...