96-8100 1-15-96

84

MECHANICAL SERVICE

HAAS AUTOMATION, INC.

SERVICE

MANUAL

VF-SERIES

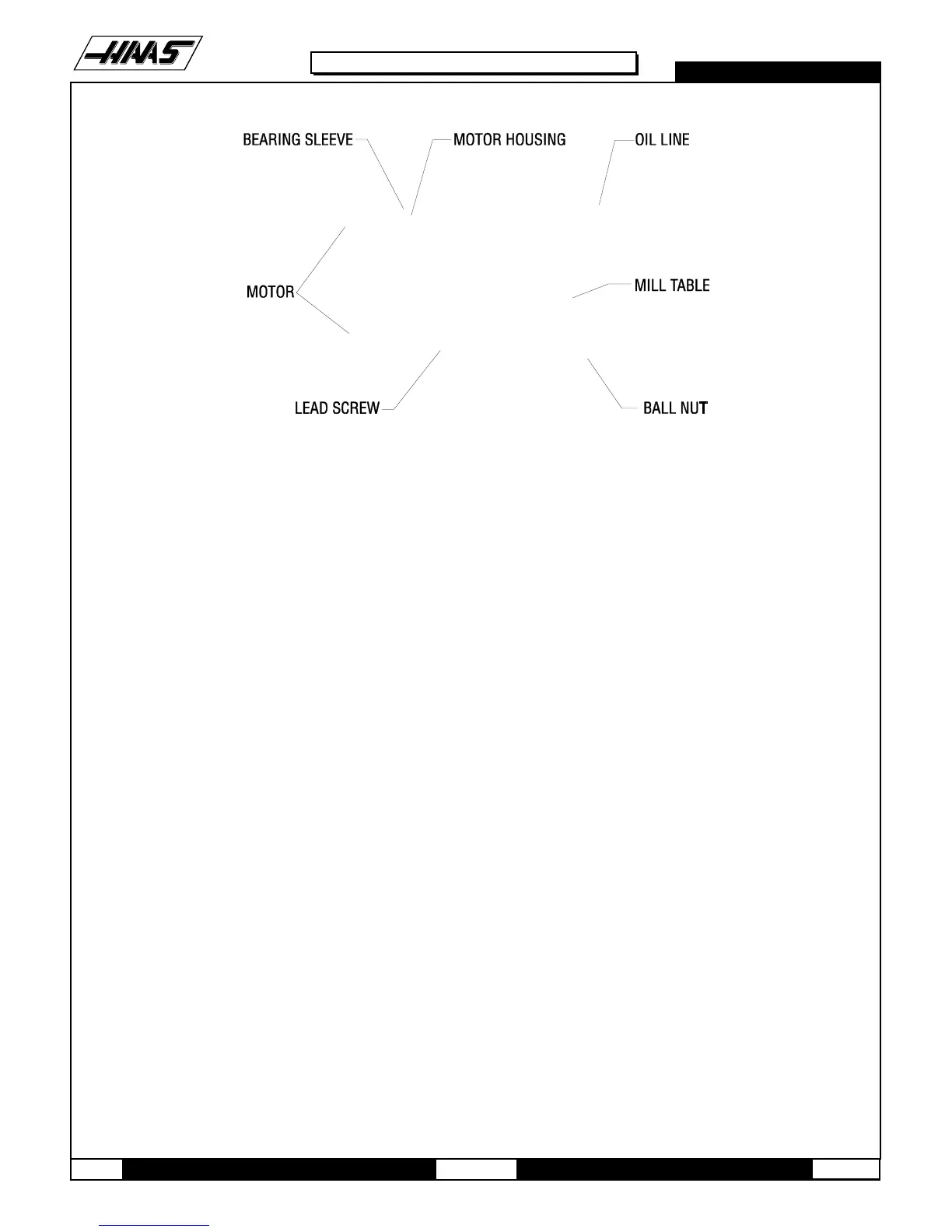

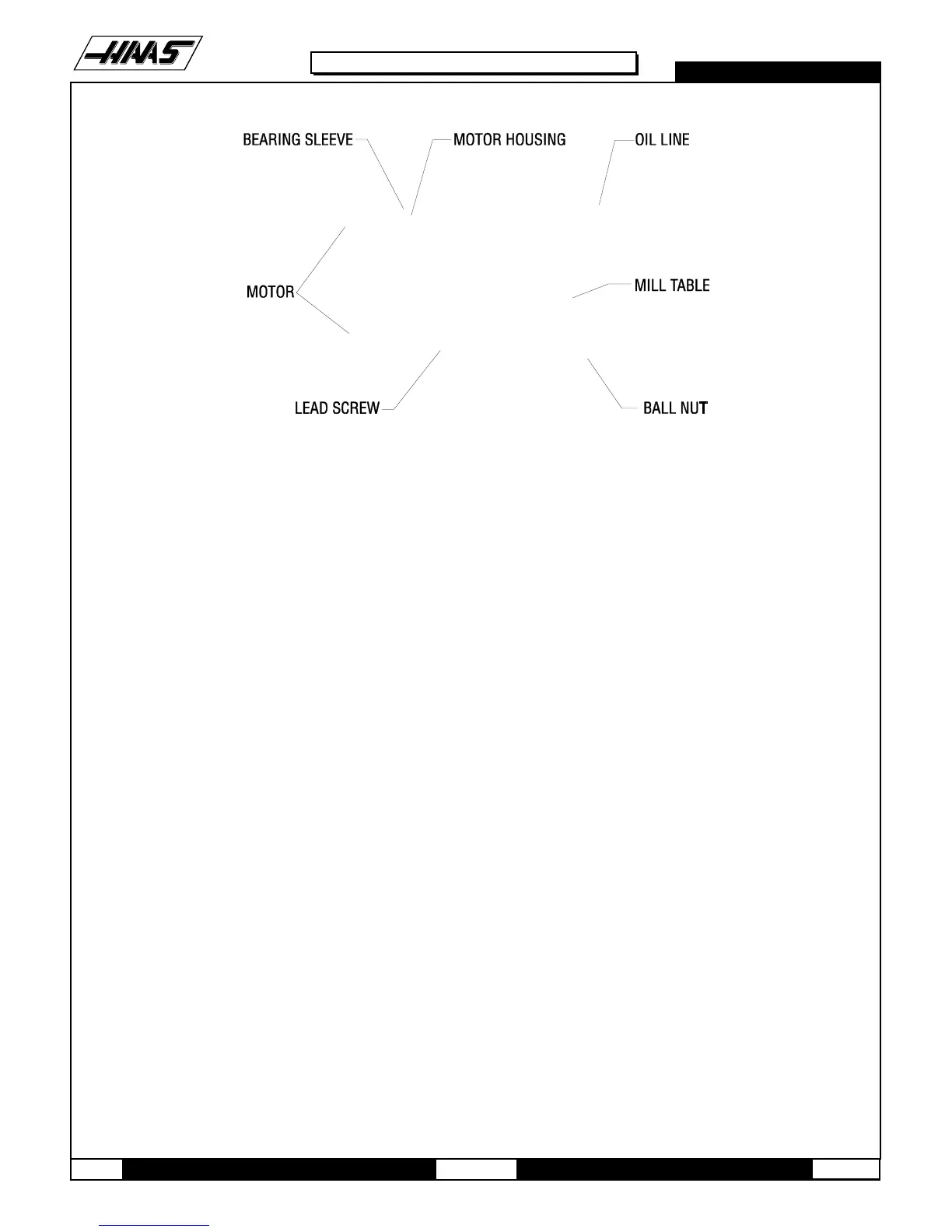

Fig. 10-2 Lead screw assembly.

8. Loosen the 10-32 x ½" SHCS and remove the clamp nut on the lead screw support bearing end.

9. Remove the axis motor in accordance with "X-Axis Motor Removal".

NOTE: The motor's electrical connections do not need to be removed for this operation. After removing motor from the

housing, set it to one side.

10. Loosen the 10-32 x ½" SHCS and remove the clamp nut on the lead screw in the motor housing.

11. Loosen the six ¼-20 x 1" SHCS and remove the bearing sleeve from the motor housing. Push on the mill table or

the opposite end of the lead screw to loosen.

CAUTION: DO NOT PRY THE BEARING SLEEVE AWAY FROM THE HOUSING. DAMAGE TO THE SLEEVE, BEARING, OR

LEAD SCREW WILL RESULT.

12. Loosen the six SHCS and remove the lead screw from the nut housing by pushing on the lead screw at the motor

end.

INSTALLATION -

1. Center the mill table on the saddle.

2. Ensure all mating surfaces on the bearing sleeve, motor housing, nut housing, and ball nut are free of dirt, burrs,

grease, or other contaminants.

CAUTION: MATING SURFACES MUST BE CLEAN OR MISALIGNMENT MAY OCCUR, SERIOUSLY AFFECTING THE

PROPER OPERATION OF THE MACHINE.

3. Insert the lead screw through the nut housing and motor housing (See Fig. 10-3), taking care not to make contact

with the screw threads, causing possible damage.

Loading...

Loading...