96-8100 1-15-96

64

MECHANICAL SERVICE

HAAS AUTOMATION, INC.

SERVICE

MANUAL

VF-SERIES

7. SETTING PARAMETER 64 (TOOL CHANGE OFFSET)

PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO SET PARAMETER 64.

NOTE: Parameter 7 must be "unlocked" before setting Parameter 64.

1. WITHOUT a tool in the spindle taper, initiate a tool change and stop the tool changer using the EMERGENCY STOP

button (when the Z-axis moves above the carousel, but before the carousel rotates). Insert a tool holder into the pocket

facing the spindle.

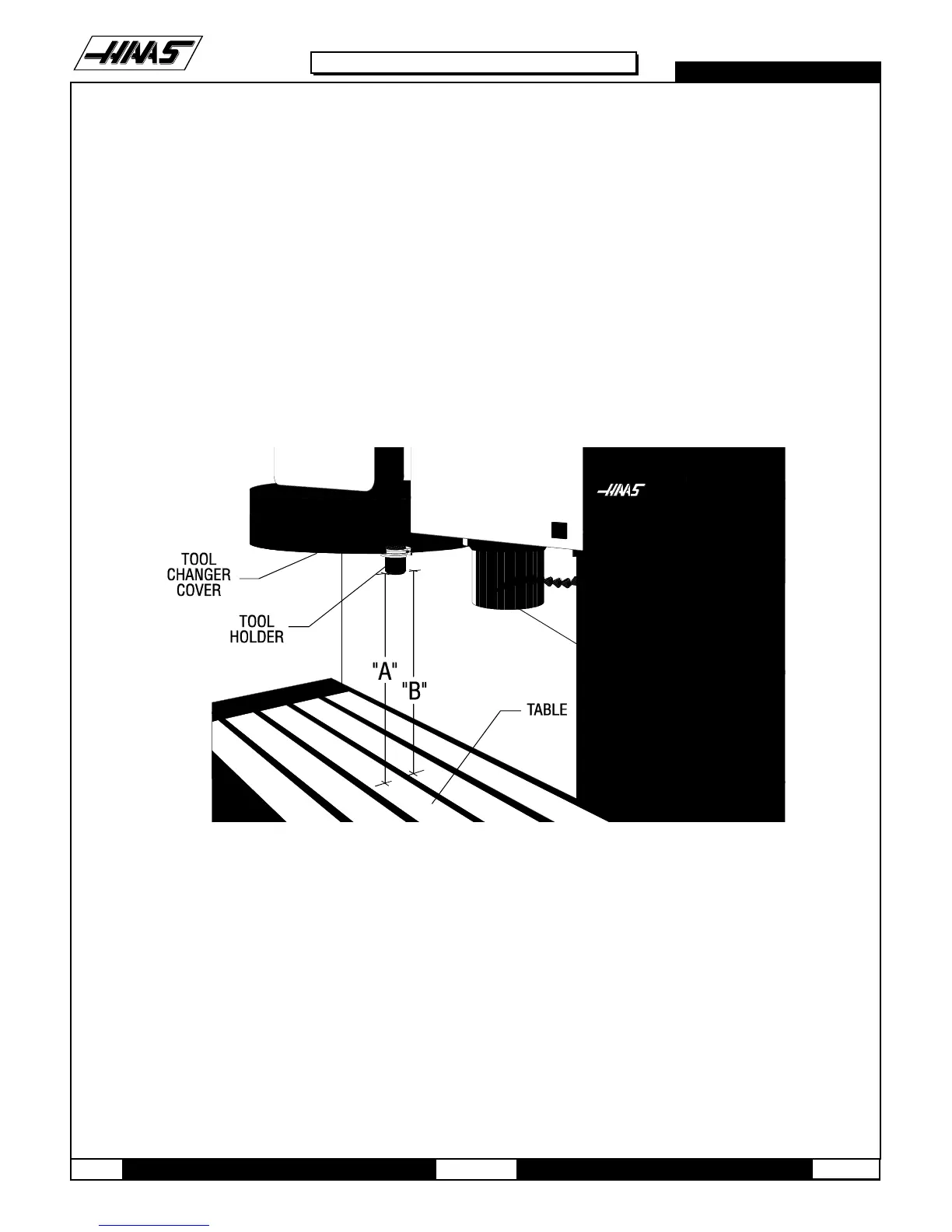

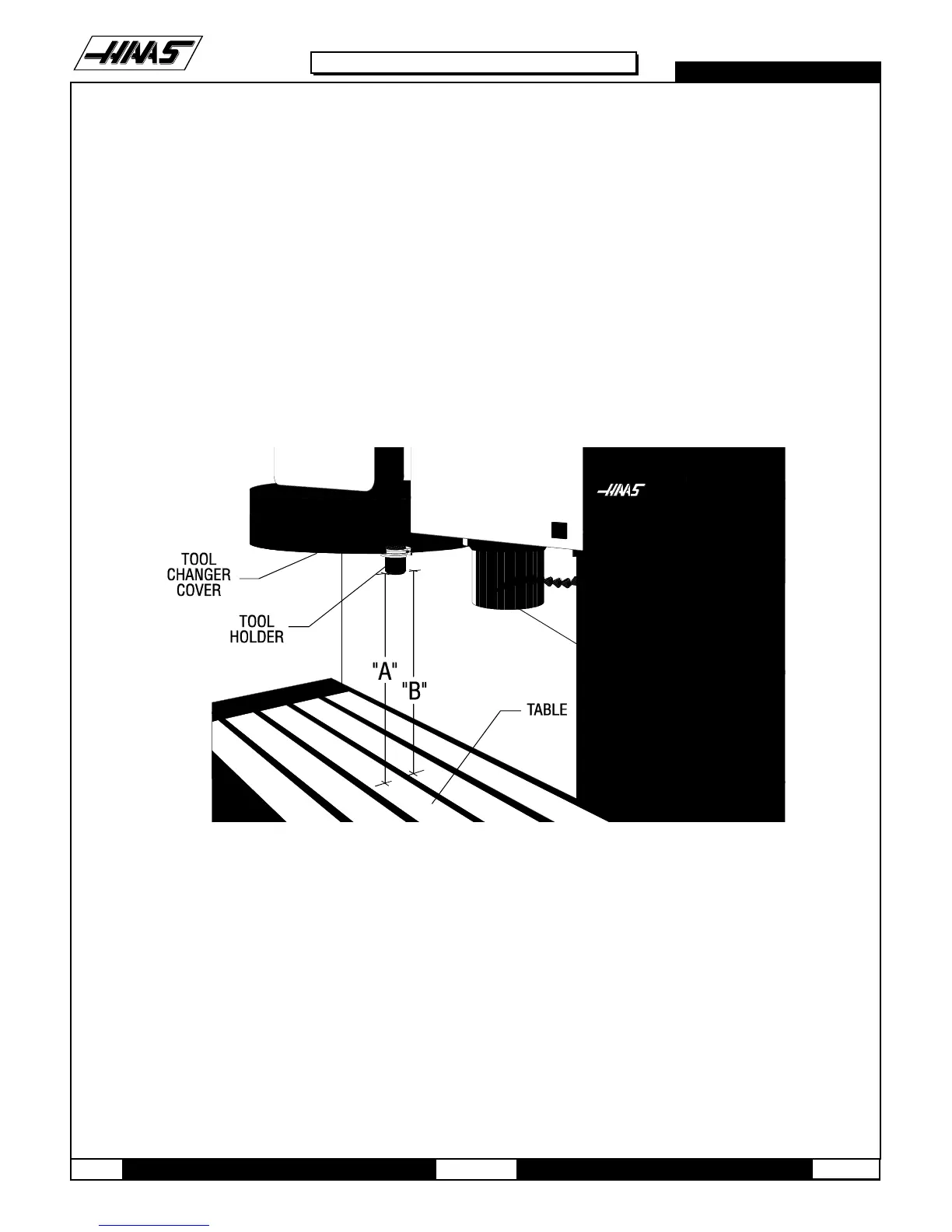

2. Using a .0005 indicator and suitable 18" mag base, zero off of bottom left edge A of tool holder (looking directly

into pocket). Move indicator to bottom right edge B of tool holder. Any difference between these edges should be

equally divided. For example: if a difference of .002 from left side to right side edge, adjust indicator dial so that

indicator reads .001 when it is on either edge. This gives you the tool offset reference.

Fig. 7-1 Checking tool offset reference.

3. Carefully (so as not to disturb relative position) move the indicator to one side. Remove tool from the tool changer

and place it in the spindle.

4. Zero return Z SIGL AXIS.

5. Carefully (so as not to disturb relative position) place indicator under spindle and indicate on bottom left edge of the

tool holder.

If spindle head is too far in the negative (-) or the positive (+) direction, go to JOG mode and choose Z-axis. Jog Z-axis

in the necessary direction until it reads zero (0).

6. Push the help button twice. This will put the machine in the calculator mode.

Loading...

Loading...