1-15-96 96-8100

13

TABLE OF CONTENTS

HAAS AUTOMATION, INC.

TROUBLESHOOTING

SERVICE

MANUAL

VF-SERIES

CHECKING Z-AXIS:

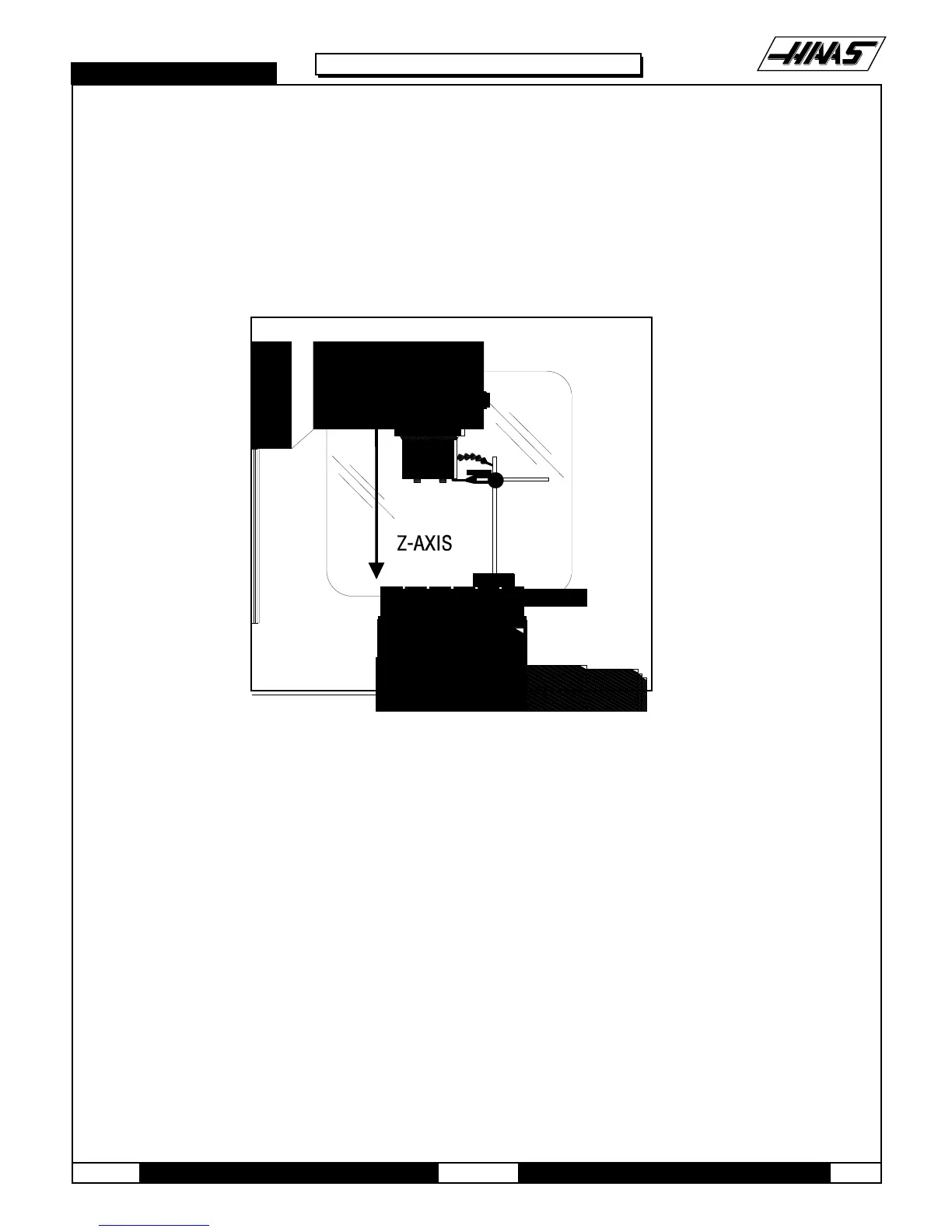

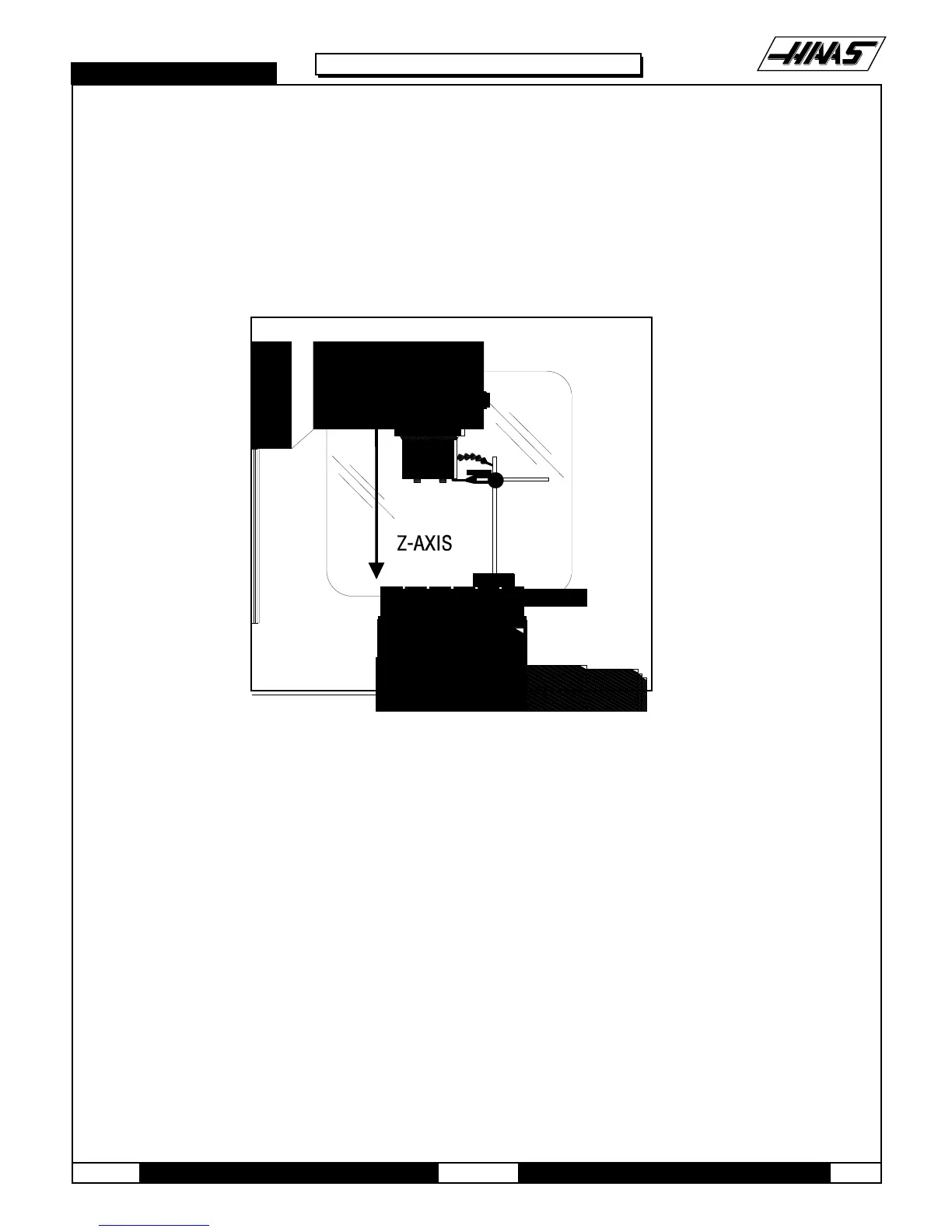

1. Set up a dial indicator and base on the mill table as shown in Fig. 3-3.

2. Manually push up and down on the spindle head while listening for a clunk. Also, watch for any rapid change in the dial

indicator. Either of these indicate possible backlash.

NOTE: Servos must be on to check for backlash in the Z-axis.

NOTE: Do not mistake deflection for backlash in the system.

Fig. 3-3 Dial indicator in position to check Z-axis.

If backlash is found in the system, check for the following possible causes:

l Loose SHCS attaching the ball nut to the nut housing. Tighten the SHCS as described in Mechanical Service.

l Loose SHCS attaching the nut housing to the mill table, spindle head, or saddle, depending on the axis.

Tighten the SHCS as described in Mechanical Service.

l Loose clamp nut on the bearing sleeve. Tighten the SHCS on the clamp nut.

l Loose motor coupling. Tighten as described in Mechanical Service.

l Broken or loose flex plates on the motor coupling.

(NOTE: The coupling cannot be serviced in the field and must be replaced as a unit if it is found to be defective.

l Loosen SHCS attaching the bearing sleeve to the motor housing. Tighten as described in "Lead Screw Removal and

Installation".

l Defective thrust bearings in the bearing sleeve. Replace the bearing sleeve as outlined in "Bearing Sleeve Removal and

Installation".

l Loose SHCS attaching the axis motor to the motor housing. If the SHCS are found to be loose, inspect the

motor fordamage and if none is found, tighten as described in "Axis Motor Removal/Installation". If damage is found,

replace the motor.

l Incorrect backlash compensation number in the parameter in the machine. Check Parameters 13, 27, and 41.

l Worn lead screw.

Loading...

Loading...