PLDC01938

REVISION 00

01/06/2011

TECHNICAL DEPT

Stavale

- date 05/09/2011

190/195

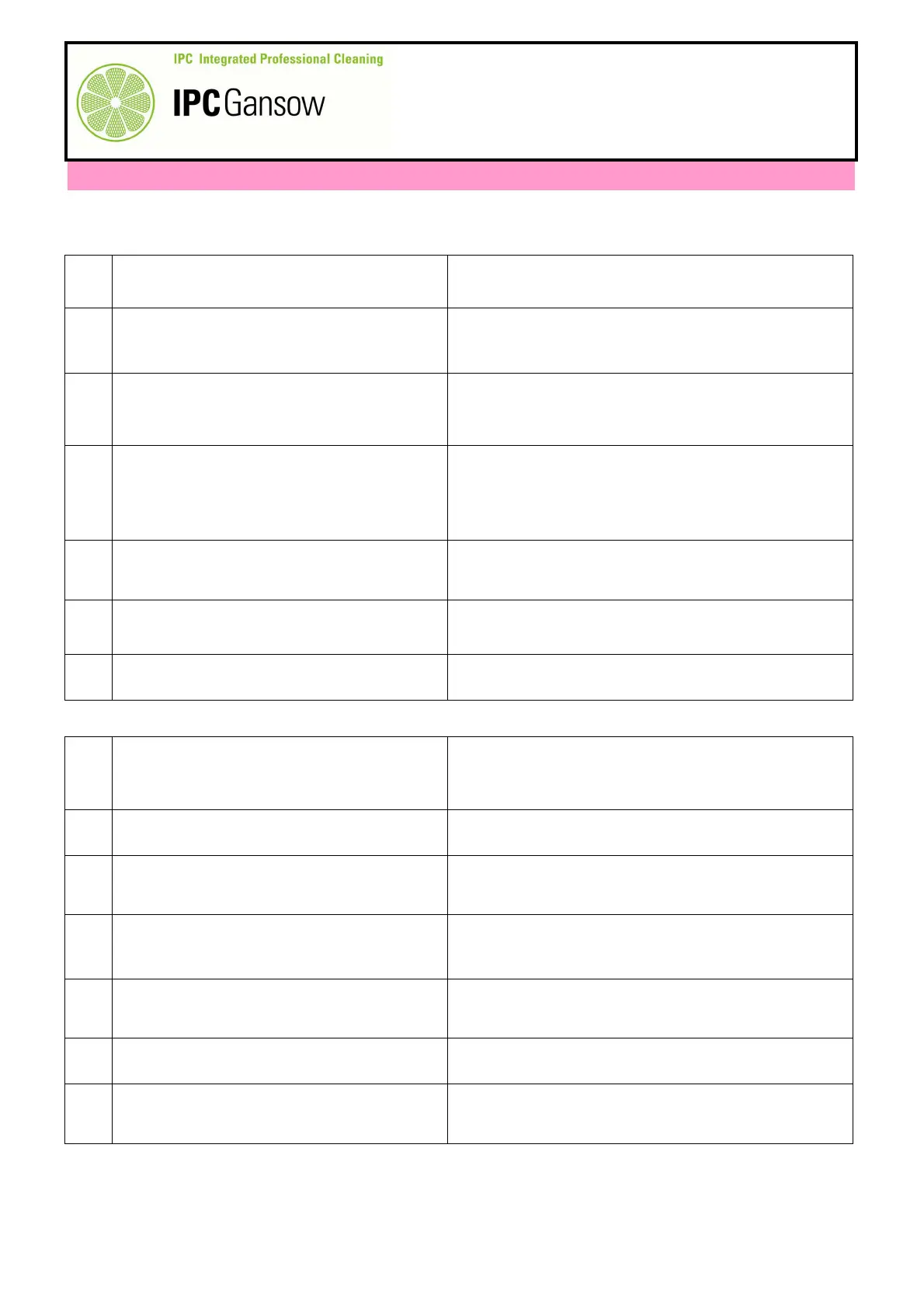

E2 TROUBLESHOOTING

E2.1 Troubleshooting

E2.1.1 The display does not light up

A

If the fuse is burnt out, replace it.

1

Check the 5 amp fuse F1.

B

If the fuse is intact, go to point 2.

A

If the voltage is less than 29 V, replace or recharge

the batteries.

2

Check that the battery voltage is at least 30 V.

B

If the voltage is more than 29 V, go to point 3.

A

If continuity is not present, check for damage to the

black-purple wire. If necessary, repair or replace.

3

Check the electrical continuity of the purple-

black power wire to the control panel board.

Between the power pin of the contactor TL1

and PIN 4 of the connector CN6.

B

If there is continuity, go to point 4

A

Continuity is not present. Check operation of the

emergency button and the state of the trace on the

circuit board Repair or replace the damaged

component.

4

Check the continuity between PIN 4 and PIN 1

and 2 of the connector CN 6.

B

If there is continuity, go to point 5

A

Use a tester to check the efficiency of the key

contacts in position “1”, otherwise replace.

5

Check there is continuity between the ignition

key contacts.

B

If OK, go to point 6

A

Restore the wire and/or the connections.

6

Check for a voltage of +36 V on the purple wire

powering the board, green connector CN4 -

PIN7.

B

If OK, go to point 7

A

Check or repair the control panel board.

7

Check the control panel board.

B

Replace the control panel board.

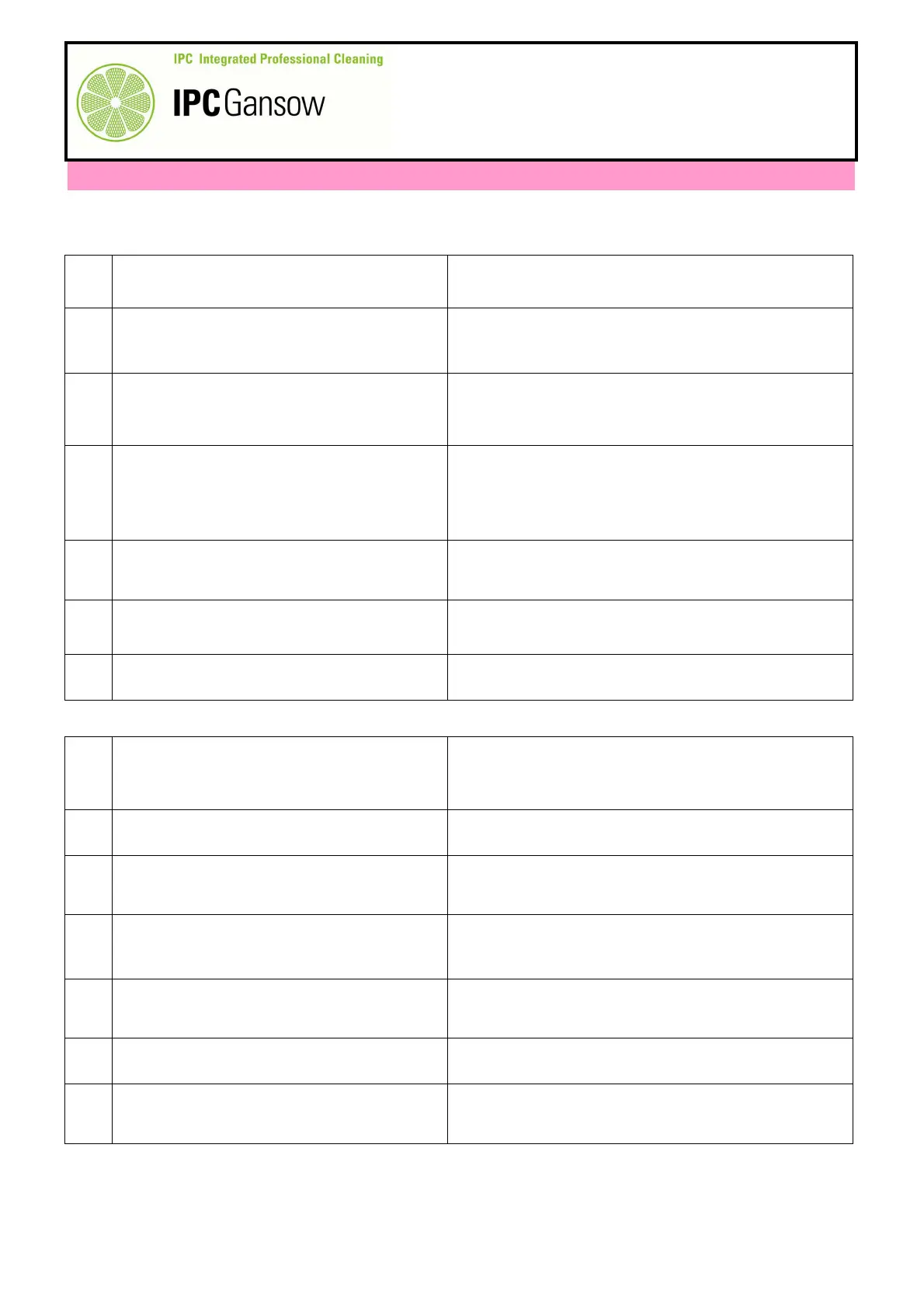

E2.1.2 The machine moves forward slowly

A

If the pedal is not working, check its operation on

the bench, see paragraph C3.2.

1

Check that the accelerator pedal is working, in

other words, that it provides the board with a

signal of between 110 - 2000 Ohms ± 100

Ohms, while the machine is moving forwards.

B

If the machine responds correctly to the accelerator

pedal, go to point 2.

A

If the sensor LED is off, go to point 3.

2

Straighten the motor wheel (ignition key on “1”)

and check that the steering sensor LED is on. *

B

If the LED is on, go to point 4.

A

If there is voltage, adjust or replace the sensor as

described in C5.1.

3

Make sure 36 V reach the black wire and red

wire on the sensor connector, wiring side.

B

If there is no voltage, restore it.

A

If maximum speed is restored, replace the

potentiometer.

4

Access the control panel potentiometer

connector, disconnect it and bridge the GREY

wire (PIN 4) and the PURPLE wire (PIN 1).

B

If there are no variations, go to point 5.

A

If the sensor LED is on and there is no voltage to

the board, go to point 6.

5

Check that there is voltage to PIN 11 on the

drive board LOGIC connector, see paragraph

C1.2.

B

If there is voltage, go to point 7

A

If there is no continuity, restore it.

6

Check the continuity of the brown wire on the

sensor connector, wiring side.

B

If there is no continuity, go to point 7

A

If speed is restored, check the continuity of the

control panel potentiometer wires.

7

On the LOGIC connector, bridge PIN 4 and

PIN 1 to exclude the control panel wiring

potentiometer.

B

If speed is not restored, replace the drive board.

*

Irrespective of the position of the control panel potentiometer, actuation of the sensor is always perceptible.

Loading...

Loading...