PLDC01938

REVISION 00

01/06/2011

TECHNICAL DEPT.

Stavale

- date 05/09/2011

70/195

A5.3 Controlling and/or replacing the compensator

The compensator hose was introduced for the first time on the CT 230 heads to improve

distribution of the water flow to the two brushes.

Checks

1

If for any reason head operation must be checked (brush motors, solenoid valve, etc.), also check the state

of the hydraulic compensator hose on the head, with particular attention to verifying that the holes in the

compensator hose are free and not obstructed.

2

Lower the head as described in point 2 to point 10 of the previous paragraph.

3

Check that the hose clips on the hydraulic circuit are tight and there are no detergent leaks.

4

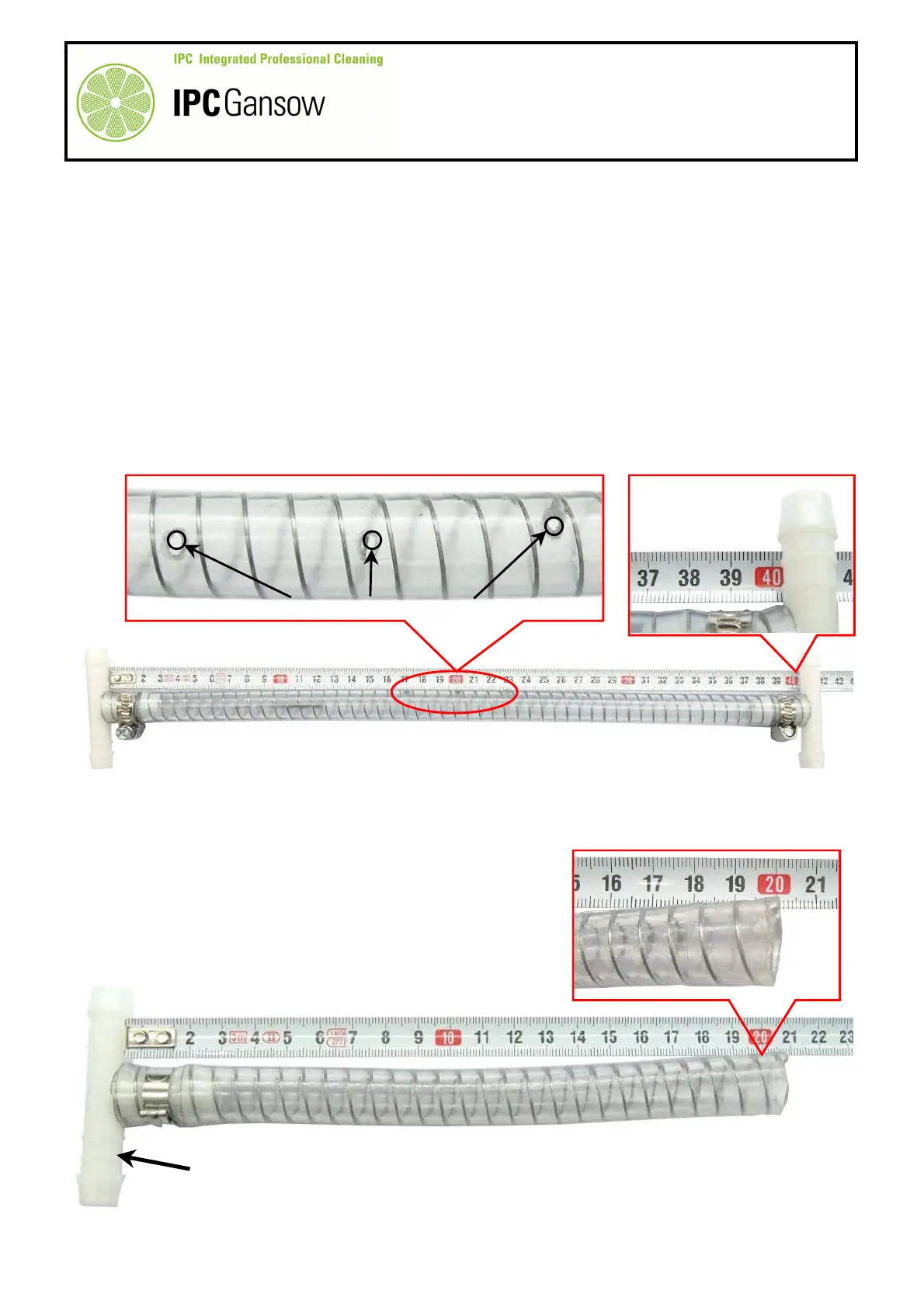

Check that the three holes A1 in the compensator hose A are free, the holes must have a diameter of 4 mm.

5

If the compensator hose A must be replaced, the recommended length is ~ 40 cm.

6

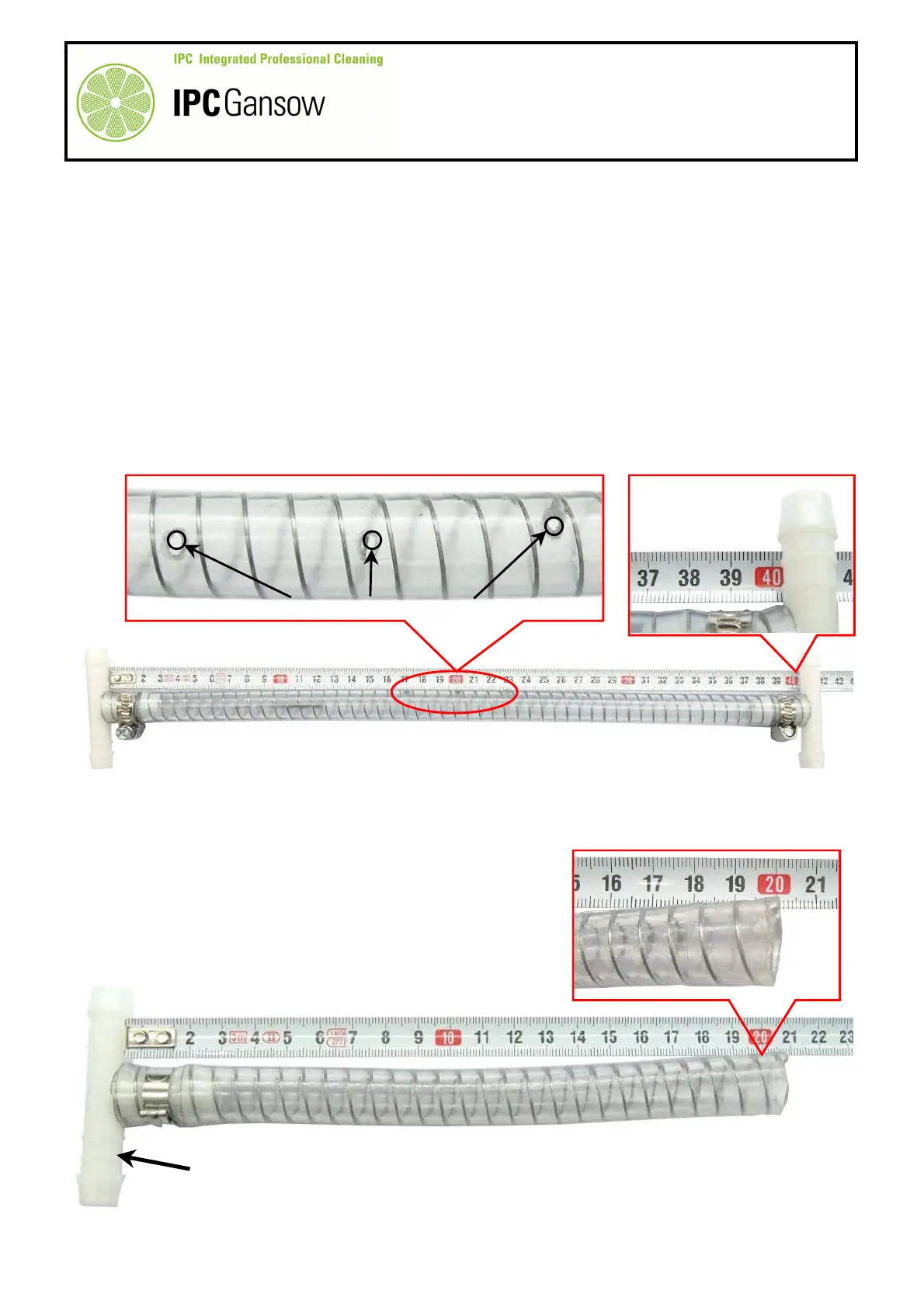

Preassemble the hose B coming from the solenoid valve to the T-junction B1. The recommended length is ~

20 cm, but it may be longer if a greater length is required.

3 x Hole Ø 4 mm

A

PHOTO 157

A

A1 A1

A1

B

B1

PHOTO 158

i

Loading...

Loading...