PLDC01938

REVISION 00

01/06/2011

TECHNICAL DEPT

Stavale

- date 05/09/2011

191/195

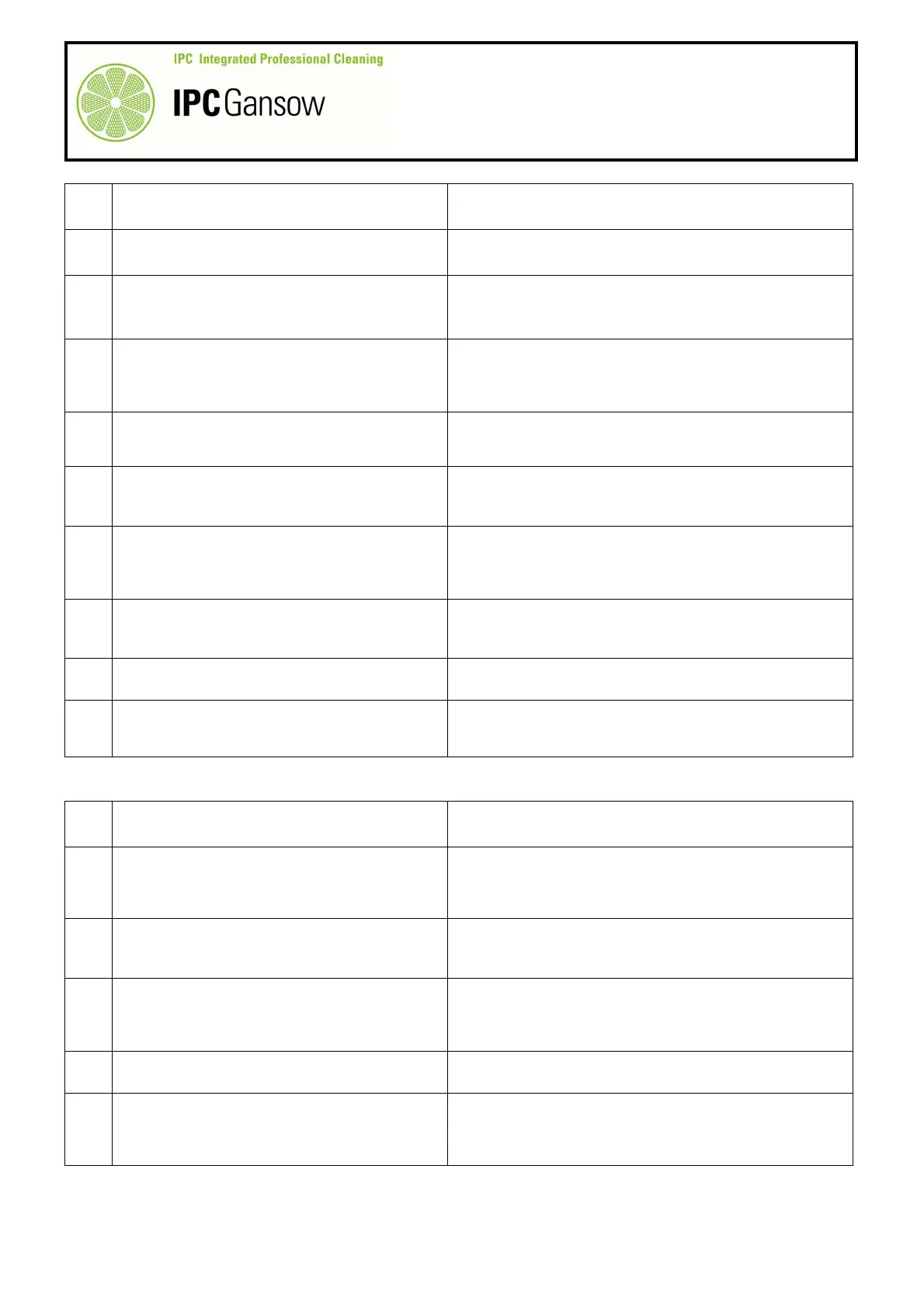

E2.1.3 The machine does not move forwards

A

Consult the message in the table E1.2.

1

Check there are no messages on the control

panel display, see paragraph E1.2.

B

If there are no messages, go to point 2.

A

Correct the error as described in table E1.1.

2

Check that the status LED on the drive board

control panel does not indicate a malfunction

B

If there are no messages, go to point 3.

A

If you do not hear activation of the contactor, go to

point 4.

3

Listen for activation of the drive contactor TL2,

see paragraph D3.1.

B

If you hear activation, go to point 7.

A

If the sensor is working correctly and there is

continuity in the connected wires, go to point 5.

4

Check operation of the operator present

sensor and bridge it if necessary.

B

If the sensor is not functioning, bridge and/or

replace it.

A

If there is no voltage, go to point 6

5

Check for a voltage of 36 V on the coil

command wires of the contactor TL2 (RED and

YELLOW-BLACK wire), see paragraph D3.1.

B

If OK, go to point 7

A

If there is no continuity, restore it by repairing or

replacing the YELLOW-BLACK wire.

6

Check the continuity of the YELLOW-BLACK

coil command wire, see paragraph C1.2 drive

board side and D3.1 contactor side.

B

If there is no continuity, go to point 7

A

If there is voltage on PIN 12 (forwards) or PIN 13

(backwards), go to point 8.

7

Check that there is a voltage of +36 V reaching

PIN 12 or PIN 13 of the drive board from the

forwards-reverse movement deviator on the

control panel.

B

If there is no voltage, restore the contacts or replace

the deviator on the control panel.

A

If there is voltage, check operation of the motor

wheel C1.1.

8

Check the output voltage at pins M-/A2 of the

drive board.

B

If there is no voltage, go to point 9

A

If there is voltage, go to point 10

9

Check there is a voltage of +36 V on the RED

wire of the board, see C1.2.

B

If there is no voltage, restore it.

A

Restore the absent signals or replace the control

panel board.

10

Check all the drive board input and output

signals, see paragraph C1.2.

Pay particular attention to PIN 6.

B

Replace the drive circuit board

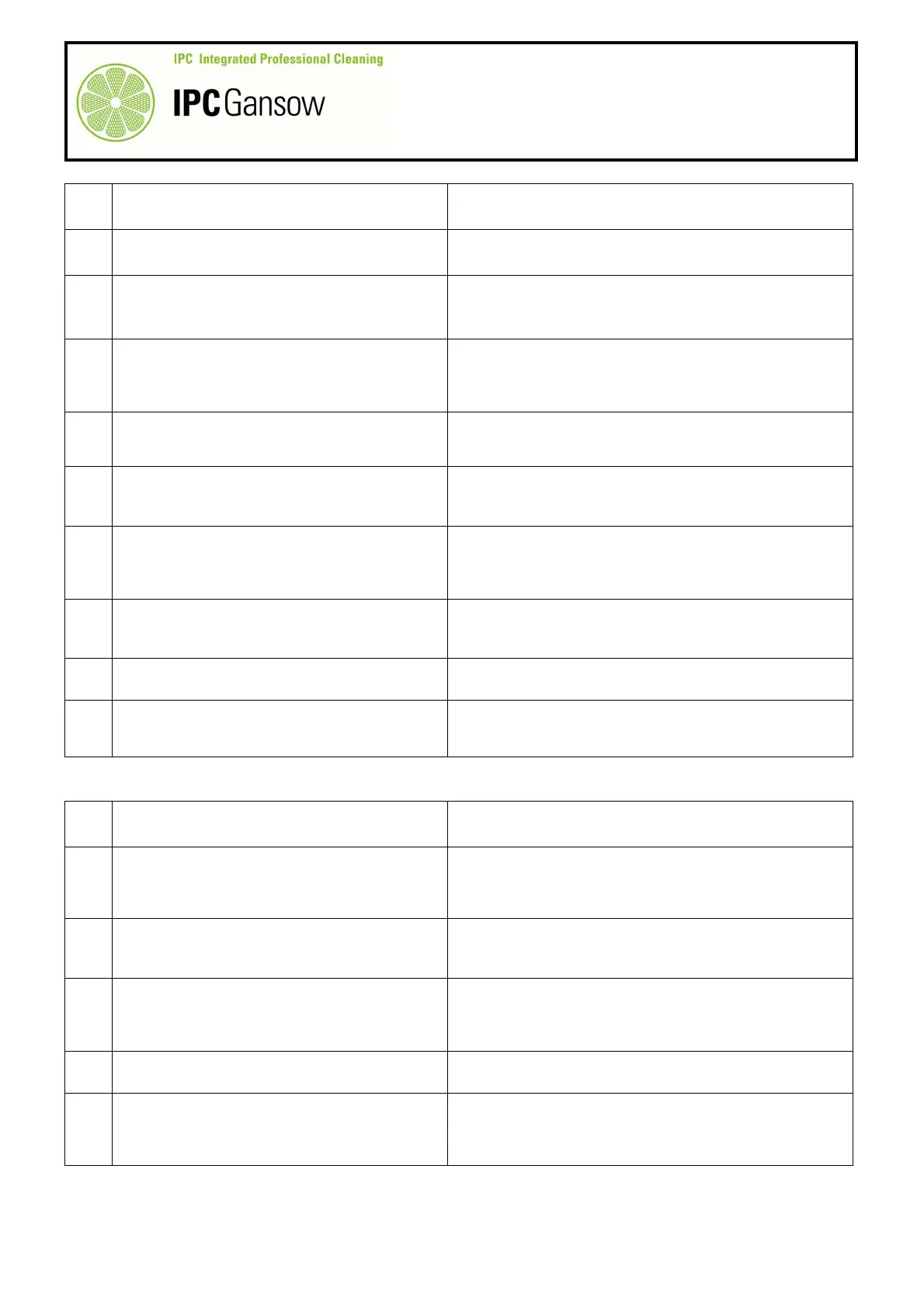

E2.1.4 The brushes do not rotate

A

Correct the error as described in table E1.2.

1

Check there are no errors on the control panel

display, see paragraph E1.2.

B

If there are no errors, go to point 2.

A

If there is voltage, go to point 3

2

With a digital multimeter, check for a voltage of

36 V between the negative wires C on the

power pin B5, see paragraph D2.1 and the

positive isolator A, see paragraph D3.

B

If there is no voltage, go to point 5

A

If there is voltage, go to point 4

3

Check for a voltage of 36 V on the Anderson

connectors F1 - F2, see paragraph A1.2.

B

If there is no voltage, check the continuity of the

power wires.

A

If the carbon brushes are worn, replace as

described in paragraph A1.3.

4

Check the state of wear of the carbon brushes

as described in paragraph A1.3.

B

If the carbon brushes are in good condition, replace

the brush motors.

A

If there is voltage, go to point 6

5

Check for a voltage of 36 V at the positive B1

and negative B4 pins of the functions board.

B

If there is no voltage, restore it.

A

If there is voltage, replace the functions circuit

board.

6

With the brushes activated, check for a voltage

of between +1.6 and 1.7 V on PIN 5 of the

RED-BLACK wire of connector CN2 and PIN

22 of the control panel board.

B

If the voltage is fixed at +12 V or 0 V, replace the

control panel board.

Loading...

Loading...