P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Section 4 iPRO-RC™ Series Banknote Recycler Disassembly/Reassembly

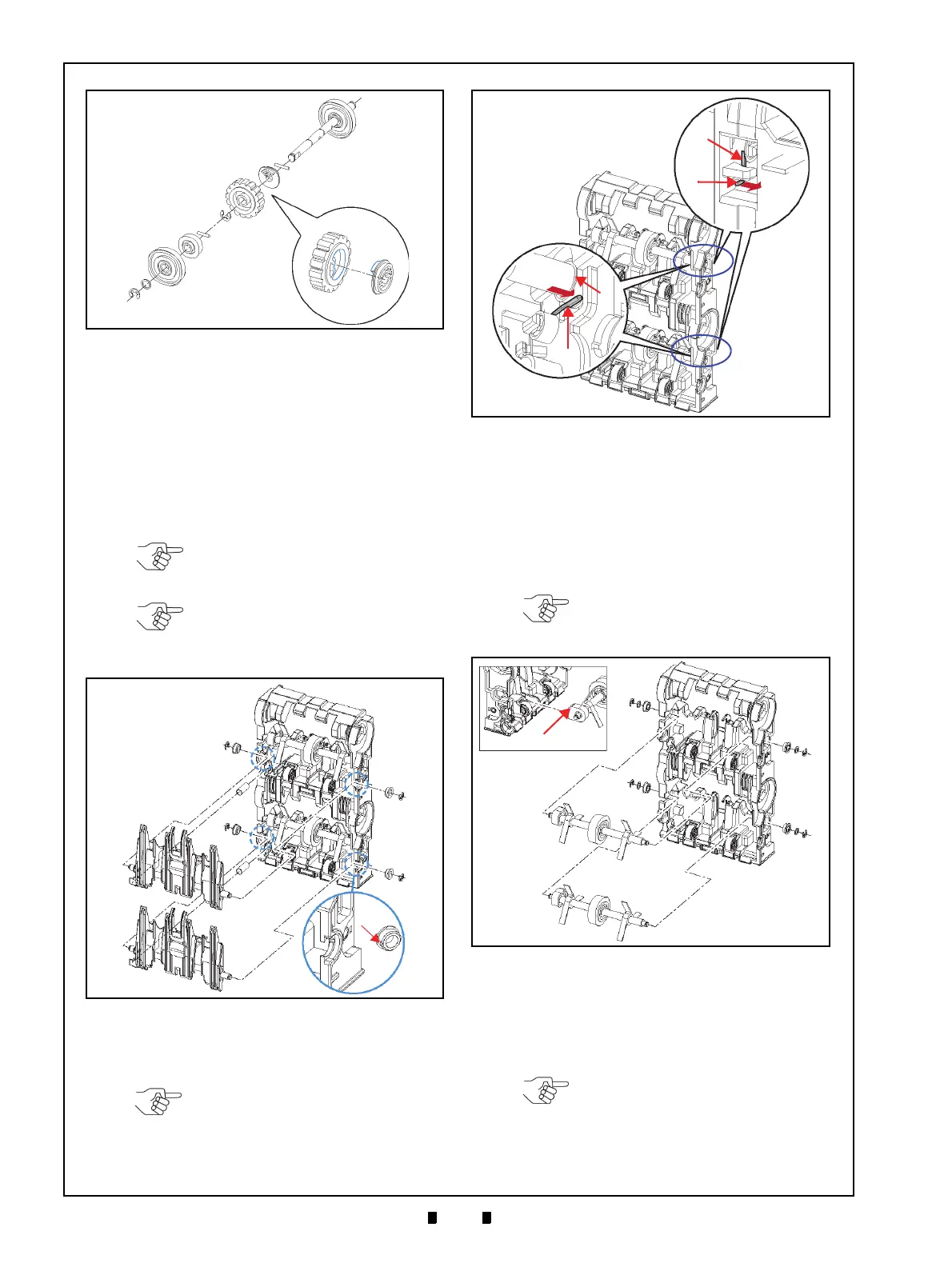

Impeller and Stop Roller Removal

To remove the Impeller and the Stop Roller,

proceed as follows:

1. Remove the four (4) E-Rings (Figure 4-31 a

1

to

a

4

) retaining the two (2) Flappers (Figure 4-31 b

1

& b

2

) in place, and remove the four (4) Plastic

Pushing Bearings (Figure 4-31 c

1

to c

4

) and Flap-

pers from the RC Course Assy..

2. Remove each of the single (1) Return Springs

(Figure 4-32 a) from th

e RC Course Assy. mount-

ing hooks (Figure 4-32 b).

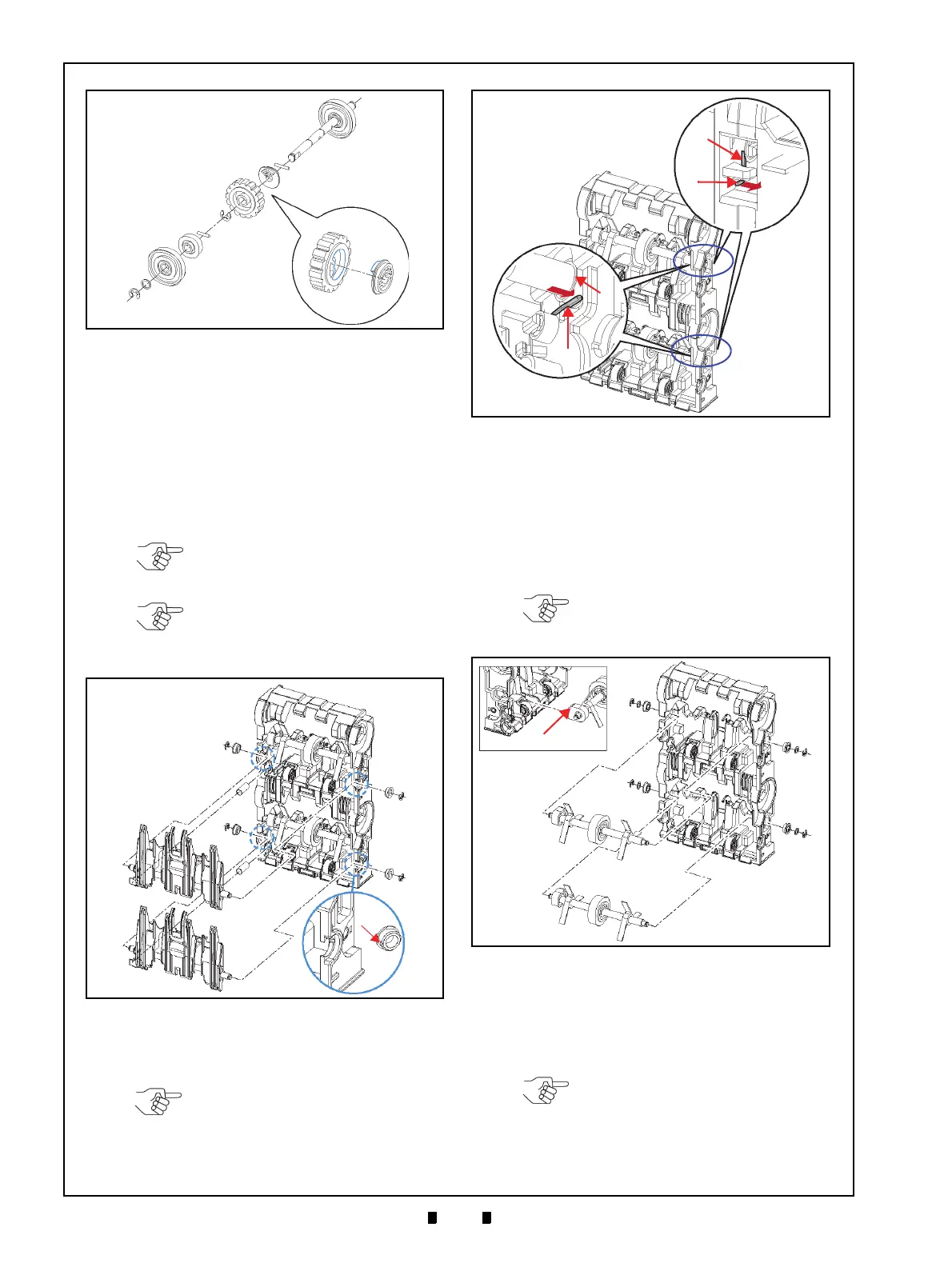

3. Remove the four (4) E-Rings (Figure 4-33 a

1

to

a

4

) retaining the two (2) Shafts (Figure 4-33 b

1

&

b

2

) in place.

4. Remove the two (2) Shafts, the four (4) related

Beari

ngs (Figure 4-33 c

1

to c

4

) and the four (4)

Poly Vinyl Sliders (Figure 4-33 d

1

to d

4

) from the

RC Course Assy..

5. Remove the two (2) Impellers (Figure 4-34 a

1

&

a

2

) and the One-Way Holder (Figure 4-34 b) from

the Shaft (Figure 4-34 c).

6. Remove the single (1) E-Ring (Figure 4-34 d) an

d

the Stop Roller (Figure 4-34 e) from the

Shaft.

Figure 4-30 Feed Roller Removal

Figure 4-30 Feed Roller Removal

NOTE: Be careful that the Springs

(Figure 4-31 d

1

& d

2

) are not lost

when removing the Flappers.

NOTE: When re-assembling the

Plastic Bearing Bushing, align the

groves to the cut area in the RC

Course Assy. (Figure 4-31 f).

Figure 4-31 Flapper Removals

d

1

d

2

a

1

a

2

a

3

a

4

b

1

b

2

c

1

c

2

c

3

c

4

f

Groove

Figure 4-31 Flapper Removals

NOTE: Replace each Spring back

(Figure 4-32 c) into its related

Bearing (Figure 4-32 d) position

when re-assembling Unit.

Figure 4-32 Spring Removals

Figure 4-32 Spring Removals

NOTE: Position the slanted cut

surface of the One-Way Holder up

when re-installing it (Figure 4-33 e).

Figure 4-33 Impeller Shaft Removals

a

1

a

2

a

3

a

4

b

1

b

2

c

1

c

2

c

3

c

4

e

d

1

d

2

d

3

d

4

Oblique Cut

Figure 4-33 Impeller Shaft Removals

NOTE: Be careful that the Parallel

Pin (Figure 4-34 f) is not lost.

Loading...

Loading...