P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Section 6 iPRO-RC™ Series Banknote Recycler Performance Tests

Individual Calibration and

Performance Test

This section explains the individual Calibration and

Performance Testing Procedures for each Sensor

within an iPRO-RC™ Unit. (Review “Sensor Cali-

bration and Performance Testing” on page 6-5 of

this Section for complete DIP Switch Settings).

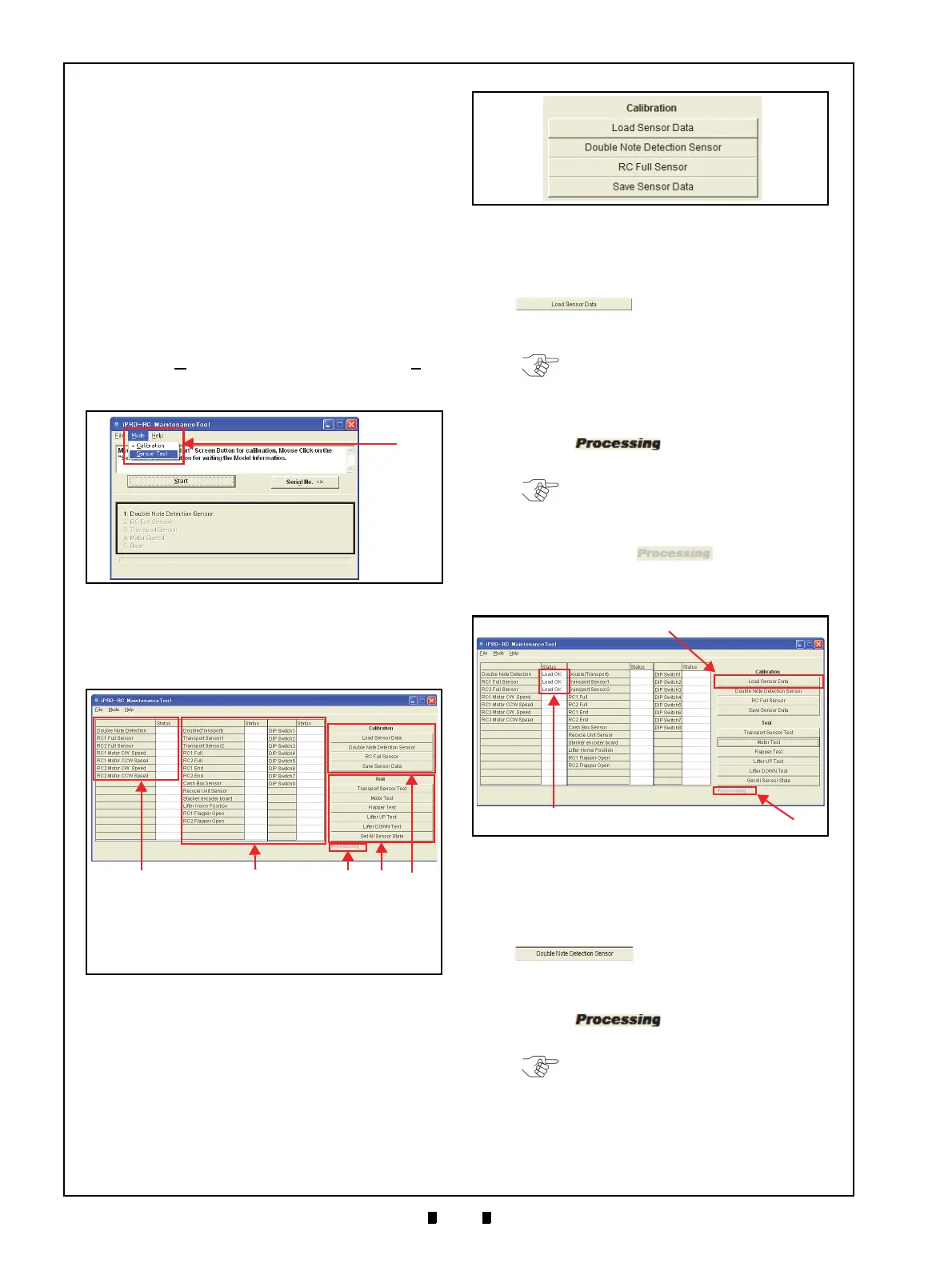

Sensor Test Screen

Individual calibration and testing is available when

the “

iPRO-RC Maintenance Tool” is in the Sensor

Test Mode. To change the Mode, proceed as

follows:

1. Click on the “iPRO-RC Maintenance Tool” Tool

Bar’s “

Mode” pull-down Menu, and select “Sen-

sor Test

” from the selections available (Figure 6-

48 a).

2. The Test Function Screen shown in Figure 6-49

will appear. Confirm that the

each Screen Button

Function and its related Status Cell indication

contains a result.

Individual Calibration

The following four (4) Function Buttons are used to

perform these related Calibrations:

• Load Sensor Data

• Double Note Detection Sensor

• RC Full Sensor

• Save Sensor Data

L

OAD

S

ENSOR

D

ATA

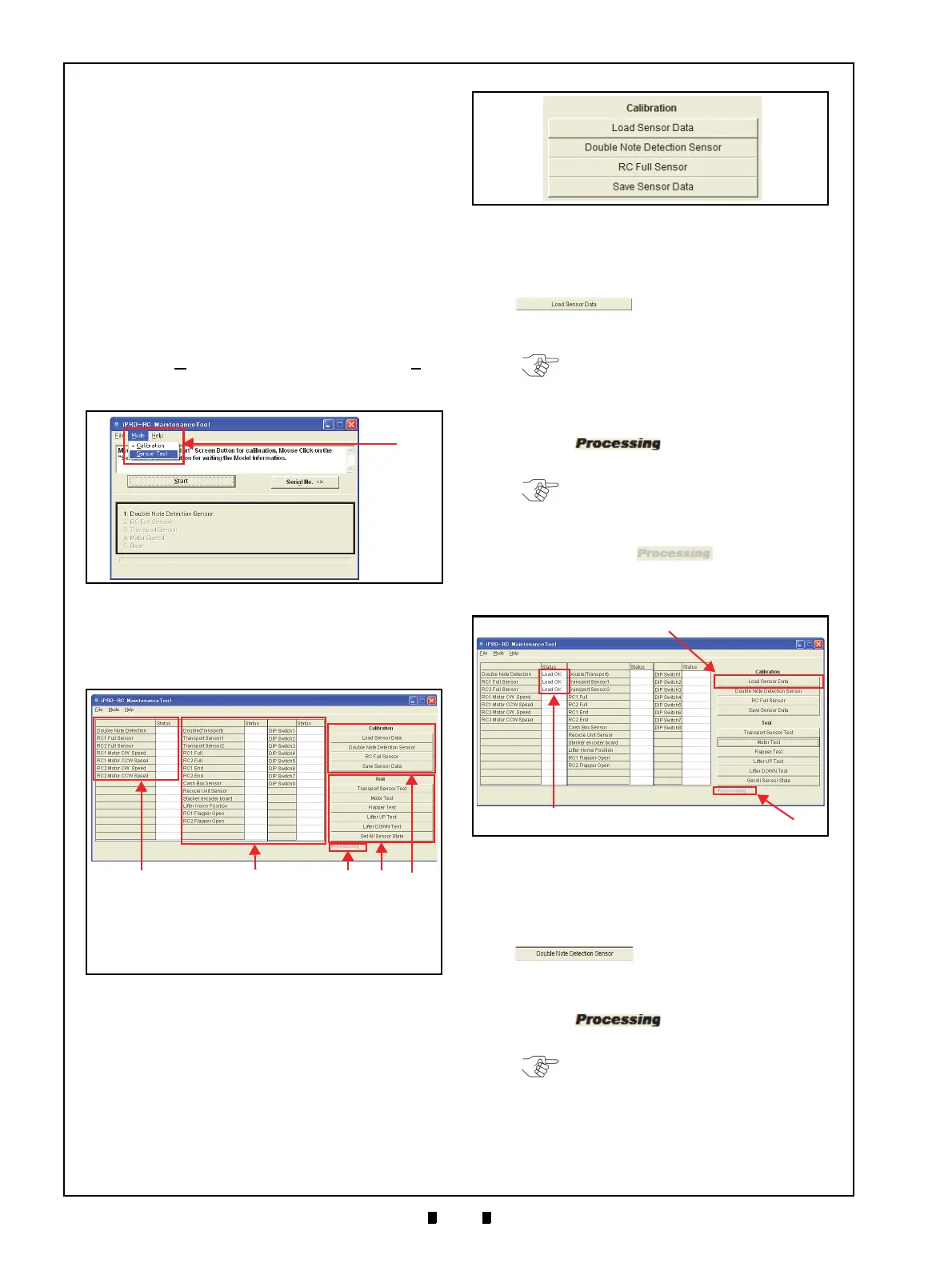

1. Click on the “Load Sensor Data”

Function Screen Button (Fig-

ure 6-51 a) to read

the current iPRO-RC™ Sensor

Data.

2. Confirm that the iPRO-RC™ Unit’s LED indi-

cates a steady Green Color

. The Bold Text “Pro-

cessing

” word appears during the

Test’s performance (Figure 6-51 b).

3. When reading current data

is complete, the Bold

Text “

Processing” word will turn to

Grayed-out text (Figure 6-51 b), and a “Load OK”

text message will appear in the related Status

resul

t Field (Figure 6-51 c).

D

OUBLE

N

OTE

D

ETECTION

S

ENSOR

C

ALIBRATION

1. Insert a piece of KS-087 Reference Paper into the

iPRO™ Transport Unit Insertion Slot.

2. Click on the “

Double Note Detection Sensor”

Calibration Screen Button

(Figure 6-52 a).

3. Confirm that the iPRO-RC™ Unit’s LED indi-

cates a steady Green Color

. The Bold Text “Pro-

cessing

” word will re-appear

during Performance Testing (Figure 6-52 b).

4. When Double Note Detect

ion Sensor Calibration

is complete, the KS-087 Reference Paper will be

returned, and the Bold Text “

Processing”

Figure 6-48 Sensor Test Selection

Figure 6-48 Sensor Test Selection

Figure 6-49 Test Function Listing Screen

Figure 6-49 Test Function Listing Screen

a) Calibration Result Indication Field

b) Performance Test Result Indication Field

c) “Processing” Indication

d) Performance Test Function Buttons

e) Calibration Function Buttons

Figure 6-50 Calibration Test Function Screen

Buttons

Figure 6-50 Calibration Test Function Screen

Buttons

NOTE: Always read the Sensor Data first

prior to starting one of the two (2) Sensor

Calibration Procedures.

NOTE: The LED will flash at a Green

Color Rate when an abnormal condition

occurs!

Figure 6-51 Load Sensor Data

Figure 6-51 Load Sensor Data

NOTE: The LED will flash at a Green

Color Rate when an abnormal condition

occurs!

Loading...

Loading...