P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Disassembly/Reassembly iPRO-RC™ Series Banknote Recycler Section 4

O-Ring (Pusher Plate) Removal

To remove the O-Rings on the Pusher Plate,

proceed as follows:

1. Remove the two (2) Mounting Screws (Figure 4-

35 a

1

& a

2

) retaining the Pusher Mechanism (Fig-

ure 4-35 b) in place, and slide

the Pusher Mecha-

nism out of the Cash Box Frame Housing.

2. Remove the six (6) O-Rings (Figure 4-36 a

1

to a

6

)

while lifting up on the Pusher Plate (Figure 4-36

b).

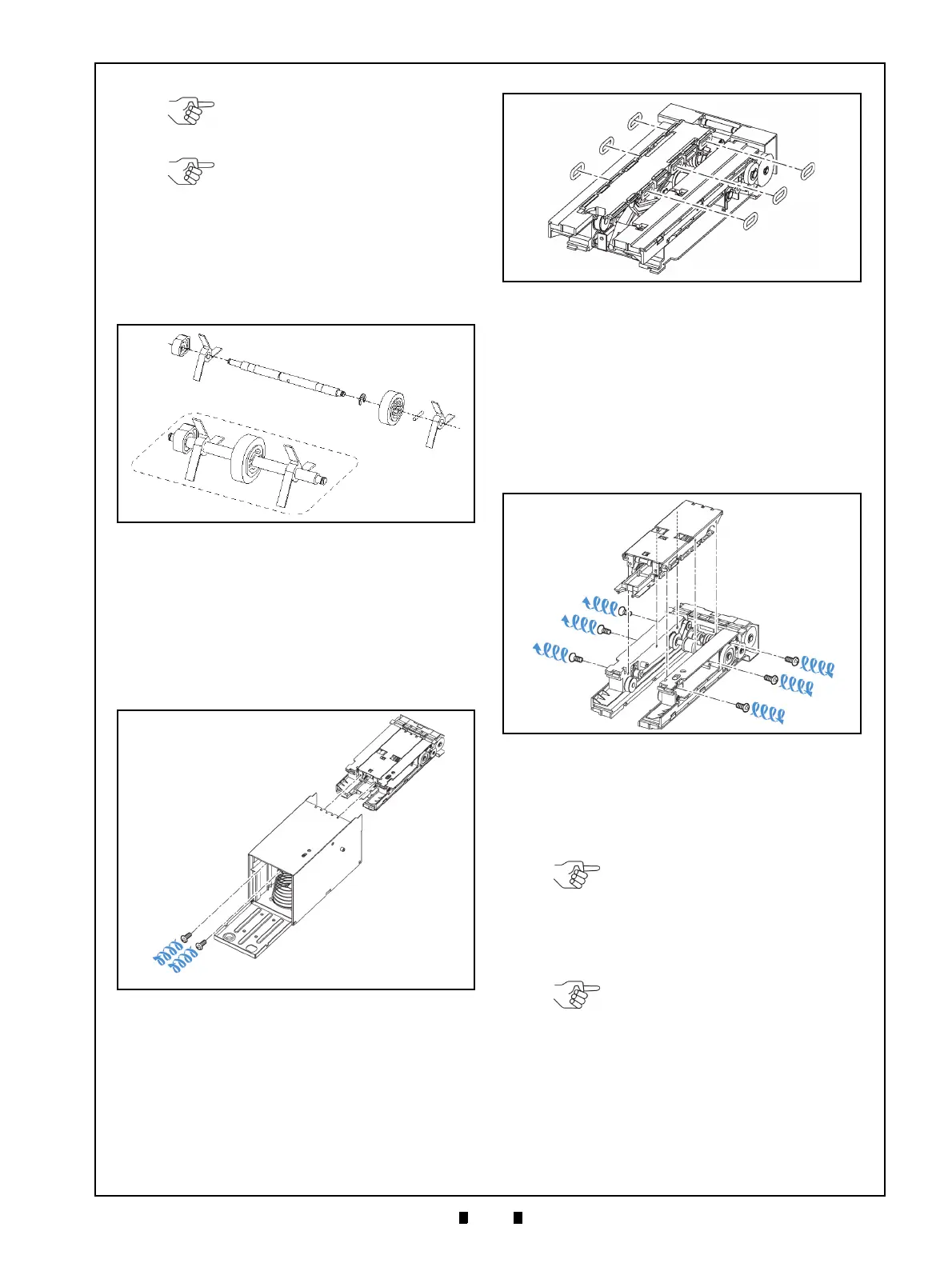

Roller Timing Belt

and O-Ring Removal

To remove the Timing Belt and O-Rings on the

Roller part of the Pusher Plate, proceed as follows:

1. Remove the six (6) Mounting Screws (Figure 4-

37 a

1

to a

6

) retaining the Pusher Plate (Figure 4-

37 b),

and take the Pusher Plate off the Pusher

Mechanism.

2. Remove the five (5) E-Rings (Figure 4-38 a

1

to

a

5

), the two (2) Gears (Figure 4-38 b

1

& b

2

) and

three (3) Bushings (Figure 4-38 c

1

, c

2

& c

3

) from

the Pusher Mechanism Assembly.

3. Remove the three (3) Frame Mounting Screws

(Figure 4-38 e

1

, e

2

& e

3

) from the Pusher Mecha-

nism Frame.

NOTE: Position the Impeller on the

slotted portion of the Shaft when re-

installing (Figure 4-34 g

1

& g

2

).

NOTE: Be sure that the Impeller

wing’s direction is tilted toward the

front, and that both sides of the

wings are set in a parallel position as

shown in the Figure 4-34 re-

assembly illustration. If the wings

are re-assembled in the wrong

direction, it can cause transportation

problems such as a Banknote Jam.

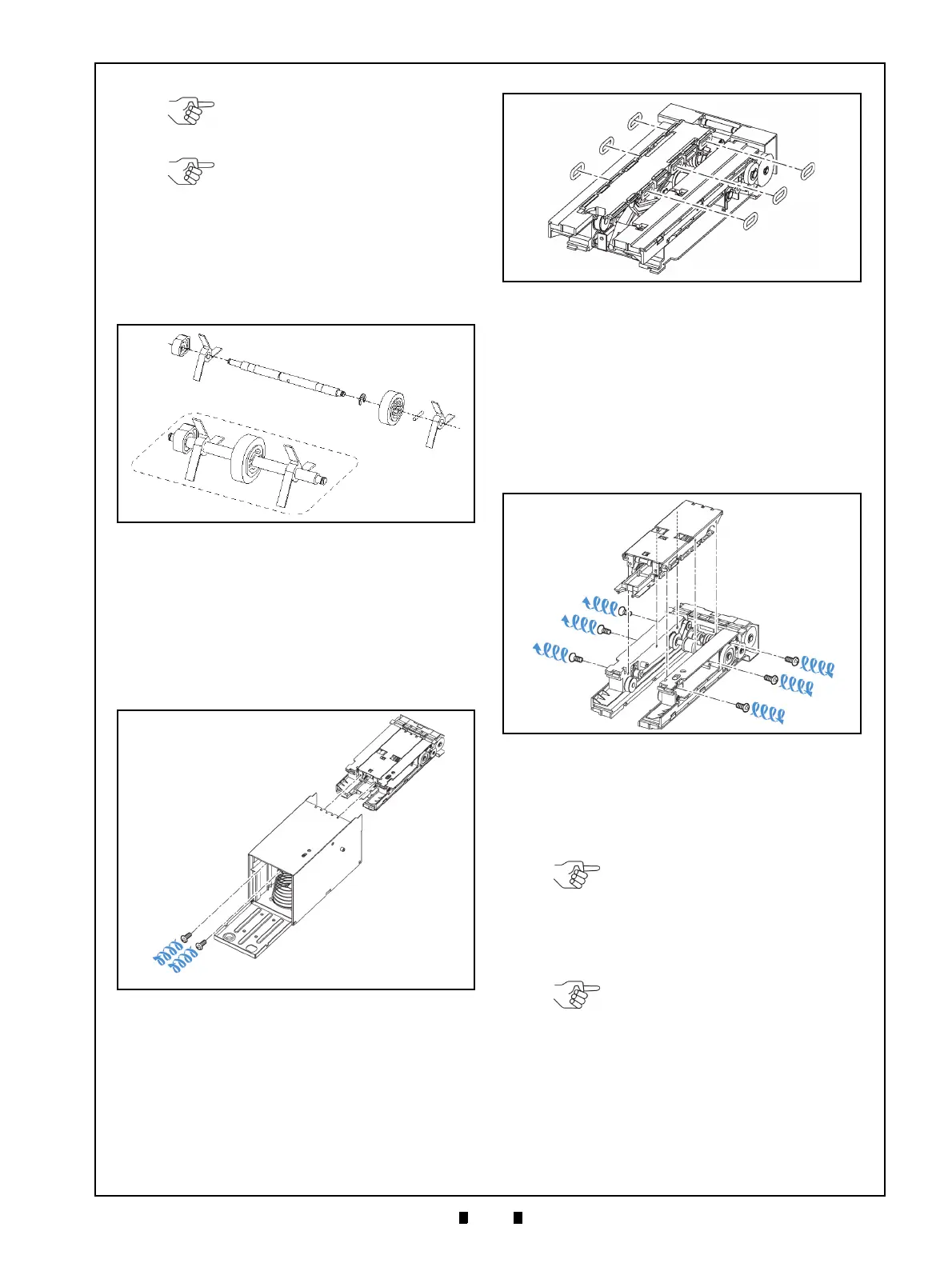

Figure 4-34 Impeller & Stop Roller Removal

Figure 4-34 Impeller & Stop Roller Removal

Figure 4-35 Pusher Mechanism Removal

Figure 4-35 Pusher Mechanism Removal

Figure 4-36 O-Ring Removals

Figure 4-36 O-Ring Removals

Figure 4-37 Pusher Plate Removal

Figure 4-37 Pusher Plate Removal

NOTE: Be careful that the Parallel

Pin (Figure 4-38 d) is not lost while

removing the Gears.

NOTE: One of the Screws is a

Phillips Self Tightening/Tapping type

(Figure 4-38 e

1

). Do not confuse its

placement with the others during re-

assembly.

Loading...

Loading...