Service and maintenance

Chapter 6 - page 4

M-HE.002.1003

• Be sparing in the use of water in the immediate environment of electronic devices, such as the laser, the robot

control box and the multiple function control box. If possible, use a soft wet towel.

Small-sized electronic parts, such as movement inductor, infrared sensor, valve for blowing the milk delivery

line empty, and so on, require little water when cleaning.

• The entire robot, gates and control area need a good clean from time to time. If this is not carried out on a

regular basis, the cleaning operations will scare off the herd. In the worst case it could last days until the herd

visits the robot as frequent as before.

• In order to eliminate contamination in the pipelines, you should manually start a rinsing session after having

cleaned parts of the milking system by hand (see section 3.4.3 ’Set Cleaning’).

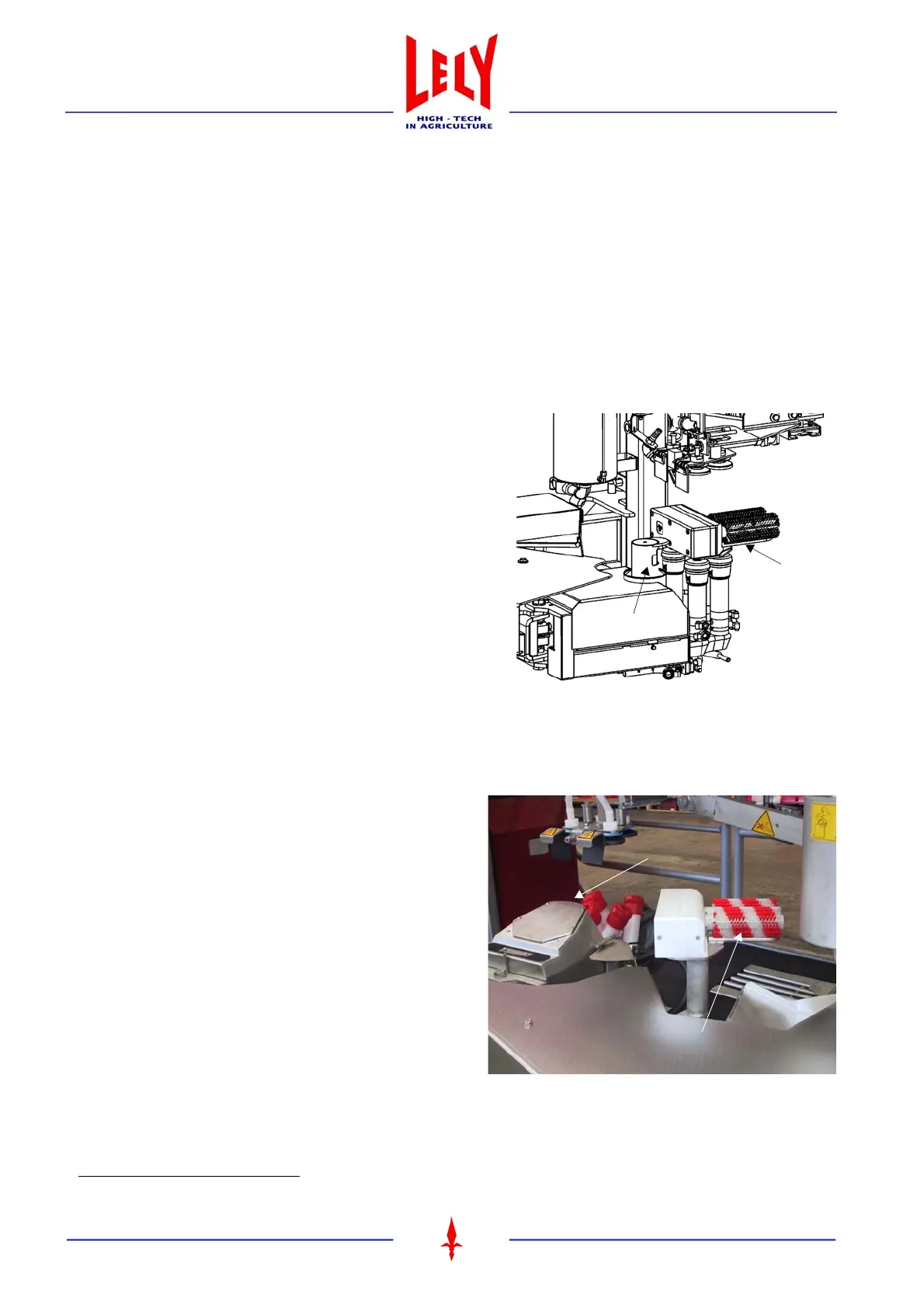

Robot arm:

Clean the laser screen/TDS

1

screen (figure 6.5) two or

three times a day using a soft cloth or towel and a little

Astri

®

-TDS. The use of this is necessary, because it

vaporises quickly. As it leaves no traces on the glass, the

outcome of the measures is not influenced.

1) TDS = Teat Detection System (where fitted)

Figure 6.4 Laser screen (old models)

Laser screen

Cleaning

brushes

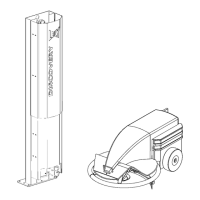

Figure 6.5 TDS screen (new models)

TDS screen

Cleaning brushes

Loading...

Loading...