Chapter 6 - page 5

Operator’s manual ASTRONAUT

M-HE.002.1003

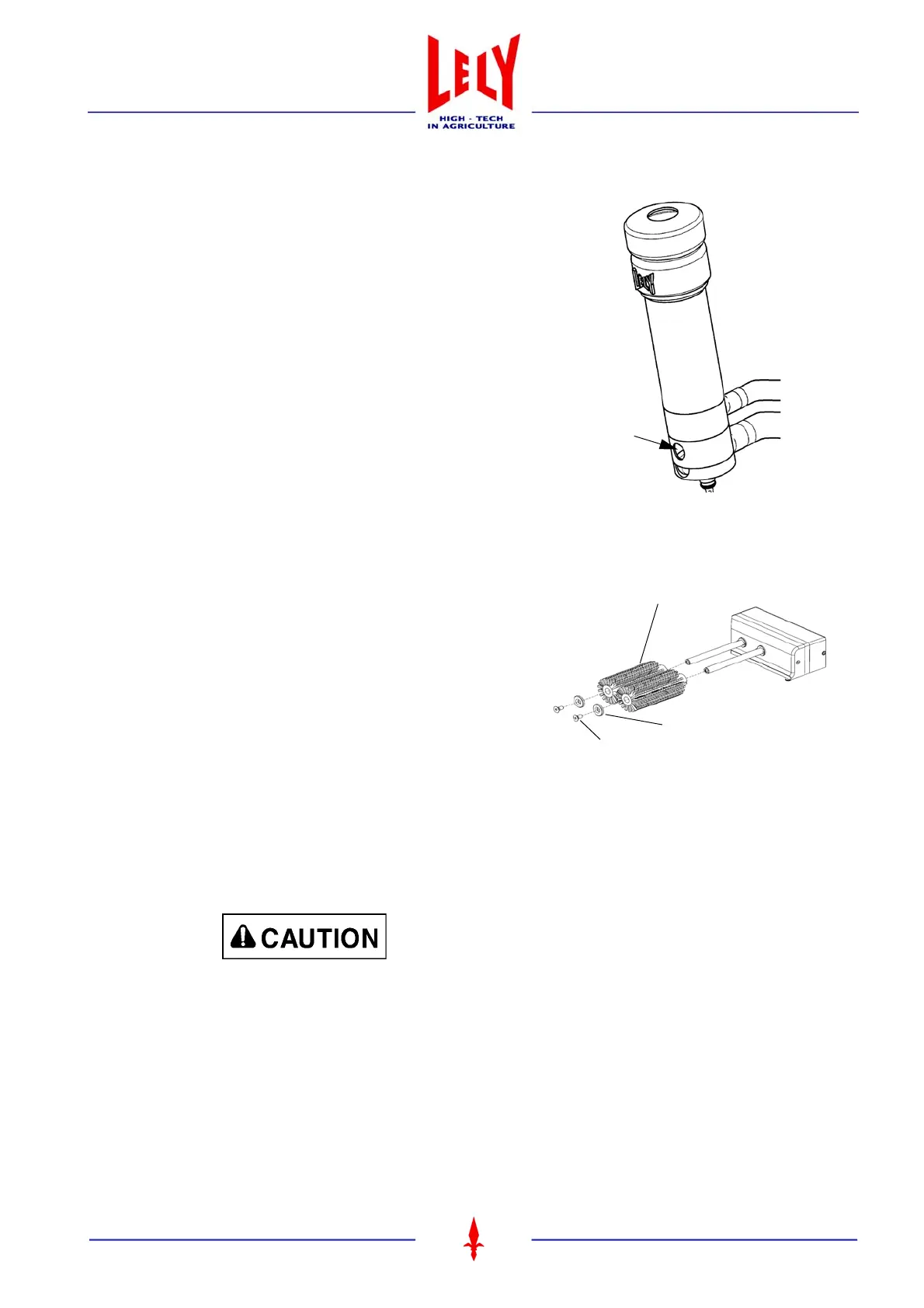

• Check if the bleed air holes (figure 6.6) are still open.

Blocked bleed air holes can be recognised by a milk column

which moves up and down in the milk tube instead of being

transported. Pierce the holes (use special bleed hole

needle) if necessary.

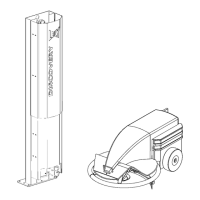

• Check the brush cleaning system for signs of damage

(figure 6.5). Replace worn brushes. Replace the cleaning

system as follows:

• Select the option "Test menu > Robot > Robot turn in

arm". For more information see section 3.4.16 ’Testmenu’.

• Disengage the allen-headed bolts and plastic washers from

the front side of the cleaning brushes (figure 6.7).

• Remove the brushes from the drive shaft.

• After replacement install the brushes to the shaft again by

means of the conical bolt and the ring.

• Leave the "Test menu".

Cleaning the brushes is essential to prevent the transfer from

bacteria from one cow to the other. The bacterial count in the

milk can increase if the brushes are not properly cleaned.

Prevent too strong a dosing to prevent irritation of the teats.

• Check the milk and pulsation tubes (figure 6.8) for damage which may be the result of cows having stood on

the tubes.

• Regularly check the teat cup cords for excessive wear and thickening. Renew if necessary.

• Damage may occur especially near the hose clamps as well as the area where the twin tube

branches into two separate tubes.

Figure 6.6 Bleed air hole teat cup

Bleed hole

Figure 6.7 Cleaning brush installation

Brushes

Plastic washer

Allen-headed bolt

Loading...

Loading...