Maintenance

Inspection guide

The purpose of this inspection guide is to aid you in identifying the intervals, based on page count, at which parts must

be inspected (for visible physical damage), cleaned, or replaced.

If any unsafe conditions exist, find out how serious the hazard could be and if you can continue before you correct the

hazard.

As you service the machine, check for the following:

• Damaged, missing, or altered parts, especially in the area of the On/Off switch and the power supply

• Damaged, missing, or altered covers, especially in the area of the top cover and the power supply cover

• Possible safety exposure from any non-Lexmark attachments

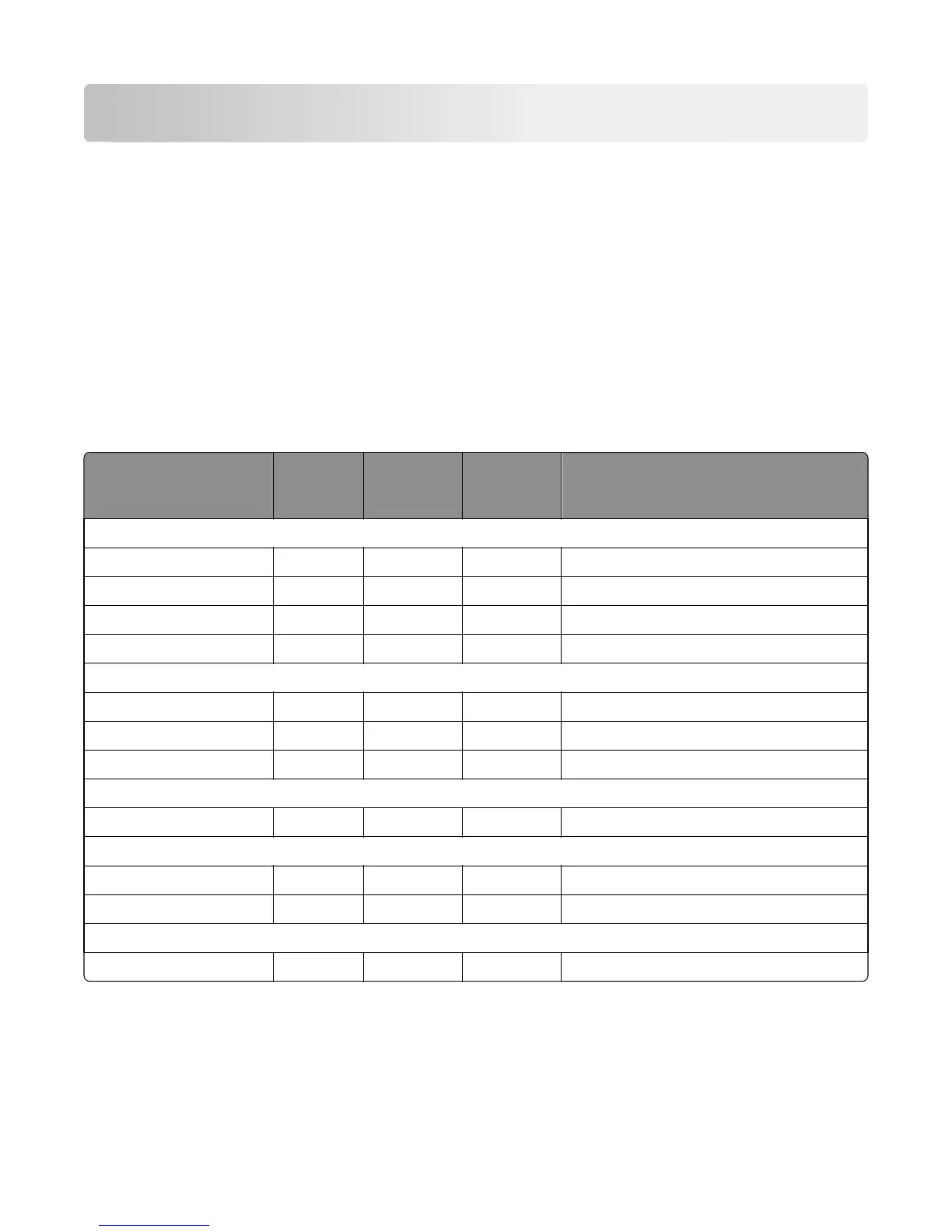

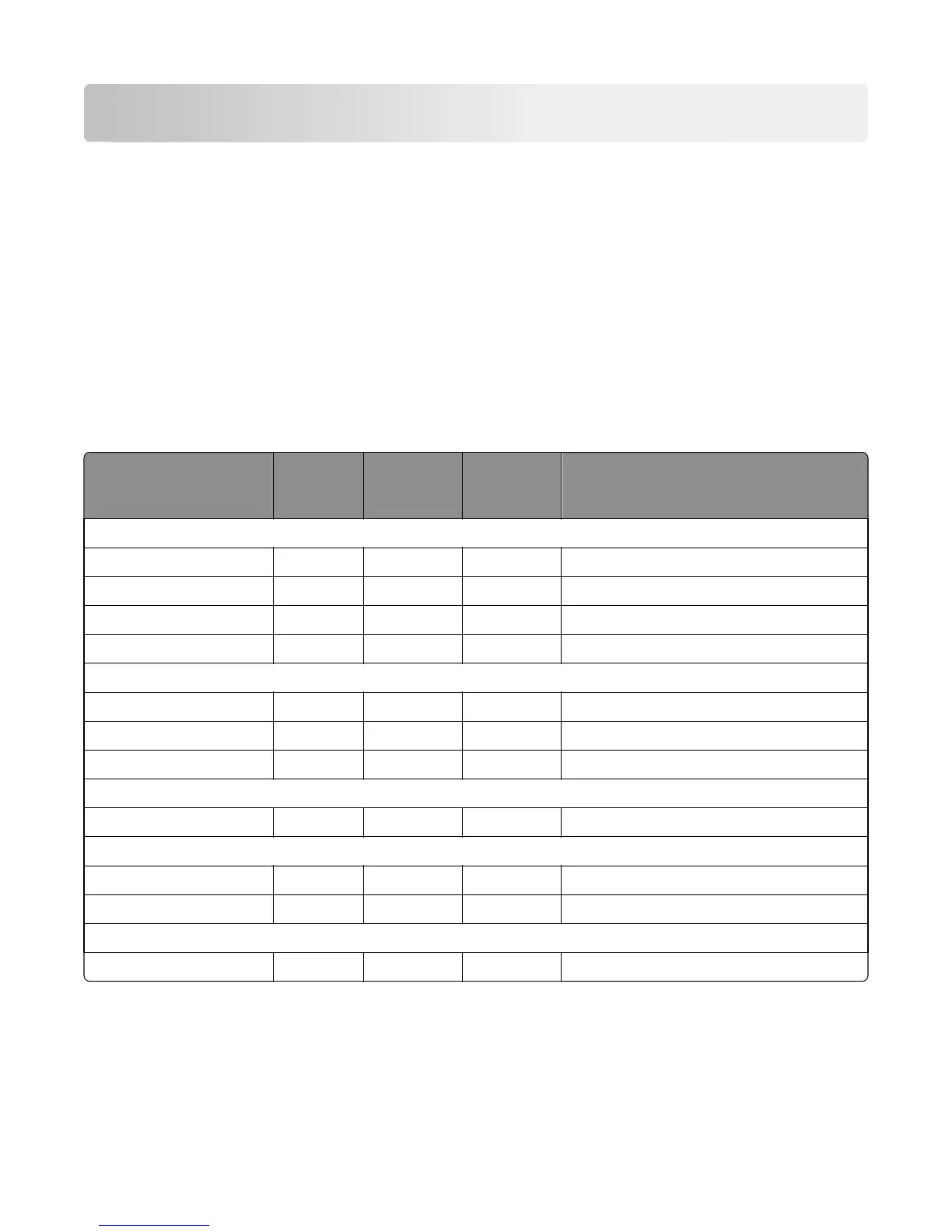

Use the following table to determine when specified parts should be inspected:

EVERY

SERVICE

CALL

EVERY 100K EVERY 200K NOTES

MEDIA TRAY—ALL

Tray insert Inspect Inspect Replace

Media side guides Inspect Inspect Check for correct positioning.

Media end guide Inspect Inspect Check for correct positioning.

Separation pad Inspect Clean Damp cloth

MEDIA FEEDERS—ALL

Pick roller Inspect Inspect Replace Verify page count before replacing.

MPF feed rollers Inspect Inspect Replace

Sensor Clean Clean Brush or blower brush

TRANSFER ROLL

Transfer roll Inspect Inspect Replace

FUSER

Fuser Inspect Inspect Replace

Sensor (fuser exit) Clean Clean Blower brush

REDRIVE ASSEMBLY

Redrive assembly Inspect Replace

Lubrication specification

Lubricate only when parts are replaced or as needed, not on a scheduled basis. Use of lubricants other than those

specified in this service manual can cause premature failure. Some unauthorized lubricants might chemically attack

polycarbonate parts. Use Grease P/N 99A0394 Nyogel 744.

4514-420, -430

Maintenance

223

Loading...

Loading...