Duplex printing

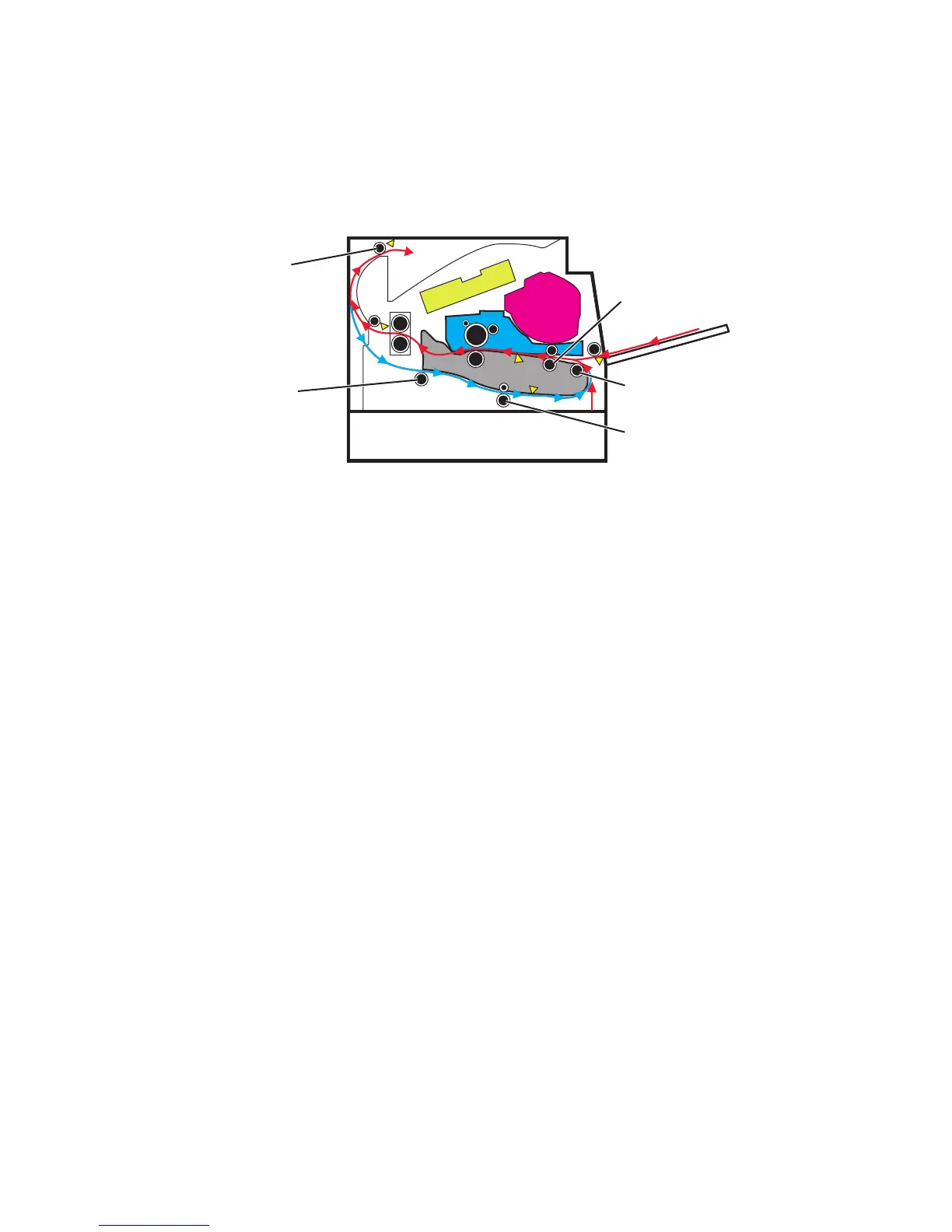

After the first side of the media has been printed on and is partially fed out to the output bin, the duplex solenoid

activates. This causes the exit roller to reverse its rotation and feed the media, with its trailing edge first, back into the

redrive assembly and then to the duplex paper path. The duplex front and rear deliver rollers move the media through

the duplex paper path, the diverter, the first input roller, and back to the primary paper path. The same process for

printing on the first side of the media repeats, this time for the second side of the media.

Secondary input

roller

First input roller

Duplex front

deliver roller

Duplex rear

deliver roller

Paper exit

roller

Media handling components

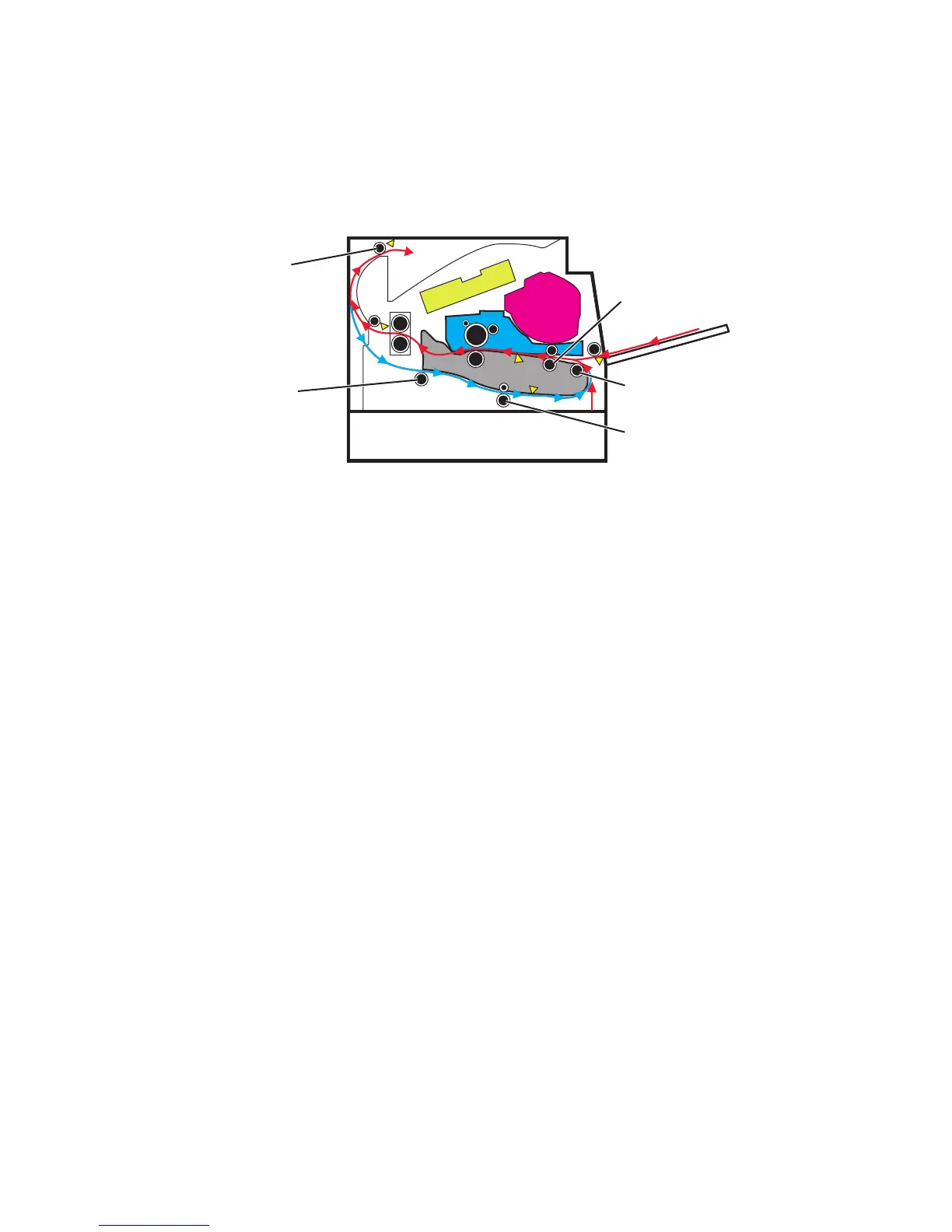

Main drive gearbox

The gearbox supplies all mechanical power requirements of the printer. Its motor, through several gears, transfers

power to following paths: photoconductor drum, transfer roll, fuser, paper exit, input, duplex, and MPF.

Aside from providing rotational motion to rollers and feeders, the gearbox must also ensure that the print image is not

distorted during the whole process. It must also provide easy and effective means to cut or break the transfer of motion

when taking the cartridge unit out of the machine, or when clearing jammed sheets through its linkage system.

Autocompensator mechanism (ACM)

The fundamental function of the ACM is to pick and feed a single sheet of media and accurately deliver it to the

downstream paper path. The pick arm is counterbalanced to provide a priming force throughout the entire range of

paper levels in the tray. When media is picked, a subsequent sheet is not picked until the previous sheet's trailing edge

is detected by the trailing edge sensor. Once the trailing edge of the media is detected, and the minimum interpage

gap is satisfied, the next sheet will be picked.

4514-420, -430

Appendix C: Theory of operation

247

Loading...

Loading...