777 SERVICE MANUAL HYDRAULIC SYSTEM

Manitowoc Published 10-01-2012, Control # 045-08 2-23

2

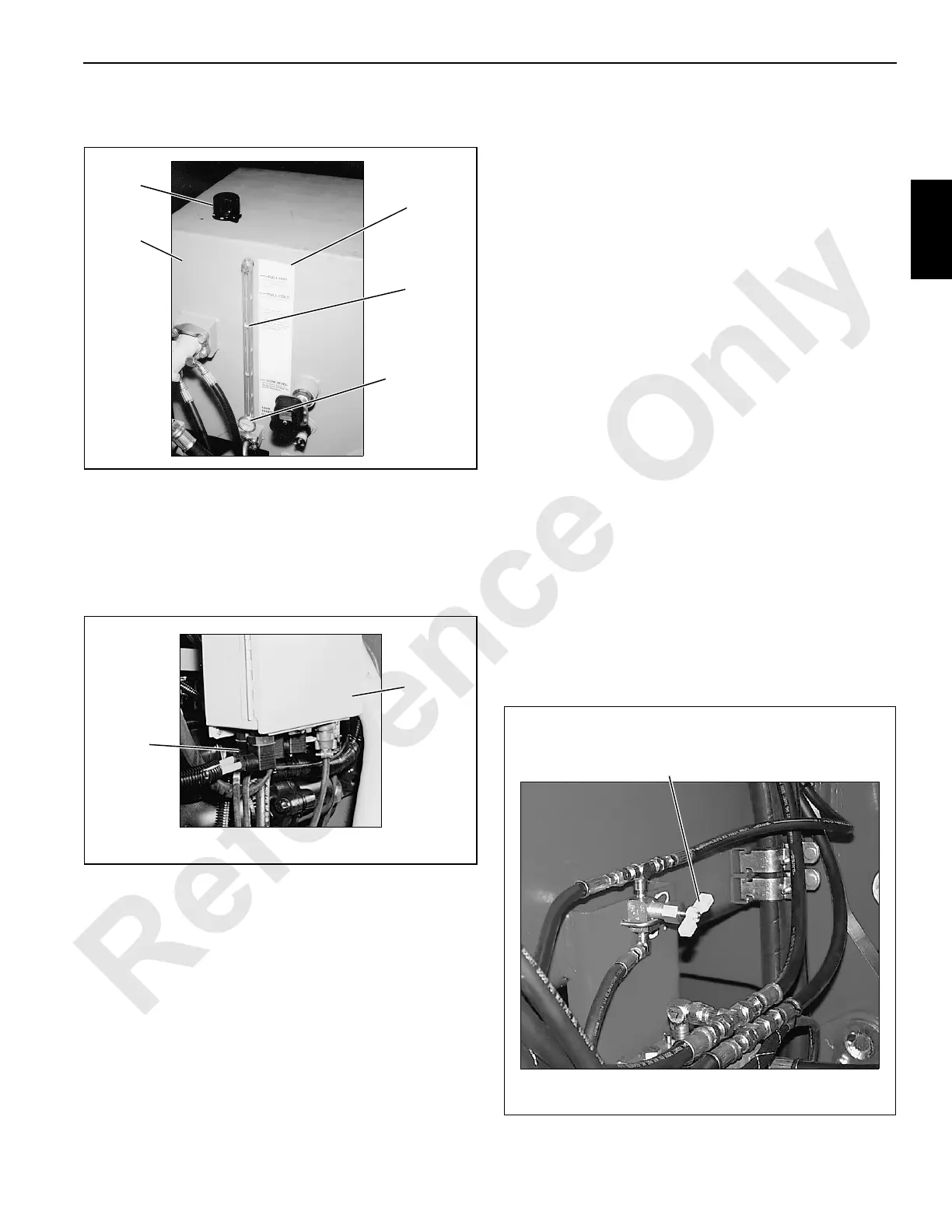

8. Fill hydraulic tank to FULL HOT level mark on sight

gauge (Figure 2-23).

9. As tank is filled, monitor bleed port at Filter 1

(Figure 2-22). Oil will flow by gravity from hydraulic tank

to filter.

Securely install cap on bleed port when clear oil flows.

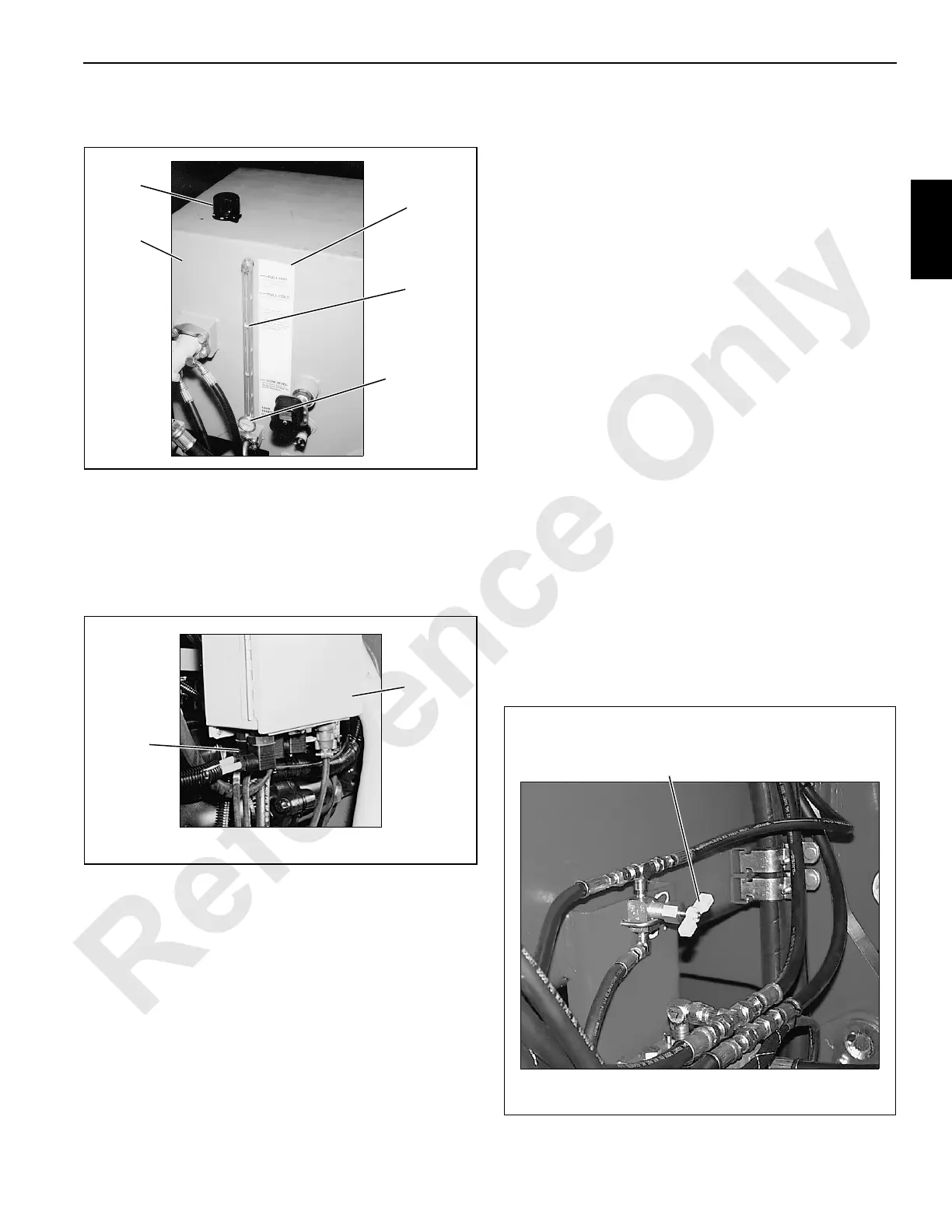

10. Disconnect fuel solenoid electrical plug (Figure 2-24) to

keep engine from starting while filling Filters 3, 4, and 6.

11. Crank engine for 10 seconds or until clear oil flows from

bleed port at Filters 3, 4, and 6 (Figure 2-22). If oil does

not appear, crank engine for 10 more seconds.

Securely install cap on bleed ports when clear oil flows.

12. Reconnect fuel solenoid electrical plug (Figure 2-24).

Pressure Sender Calibration

Perform this procedure before Initial Start-Up.

The following procedure only applies when the crane does

not a boom. When the crane has a boom, use the

procedure contained in Pressure Sender Calibration in

this section.

1. Stop engine.

2. Perform following steps for boom hoist cylinder pressure

sender before proceeding:

a. Securely close shut-off valve for boom hoist cylinder

pressure sender (Figure 2-25) — turn

CLOCKWISE.

b. Connect a bleed line with a shut-off valve to coupler

for boom hoist cylinder pressure sender (item 5,

Figure 2-27).

c. Open valve in bleed line to bleed oil. Use a suitable

container to catch oil flow.

3. Turn ON cab power switch.

4. Turn crane mode selector key counterclockwise to

CONFIRM position and hold.

5. Press engine run/stop switch to RUN position.

6. Continue to hold crane mode selector key in CONFIRM

position for ONE MINUTE after performing step 5.

7. Check for proper calibration — with engine off (key in

RUN), charge pressure on diagnostic screen for each

crane function should be 50 psi (3.4 bar) or less.

8. Remove bleed line from coupler for boom hoist cylinder

pressure sender.

9. Fully open shut-off valve for boom hoist cylinder

pressure sender (Figure 2-25). Erratic boom hoist

operation will occur if this step is not performed.

P454

Hydraulic

Tan k

Fill Cap

Level

Decal

Sight

Gauge

Temperature

Gauge

FIGURE 2-23

P438

Junction

Box

Fuel

Solenoid

Electrical

Plug

Right Side of Engine

FIGURE 2-24

FIGURE 2-25

Shut-Off Valve

for Boom Hoist Cylinder

Pressure Sender

Turn CLOCKWISE to CLOSE

Between Rear Drum

and Hydraulic Tank

P985

Loading...

Loading...