HYDRAULIC SYSTEM 777 SERVICE MANUAL

2-10 Published 10-01-2012, Control # 045-08

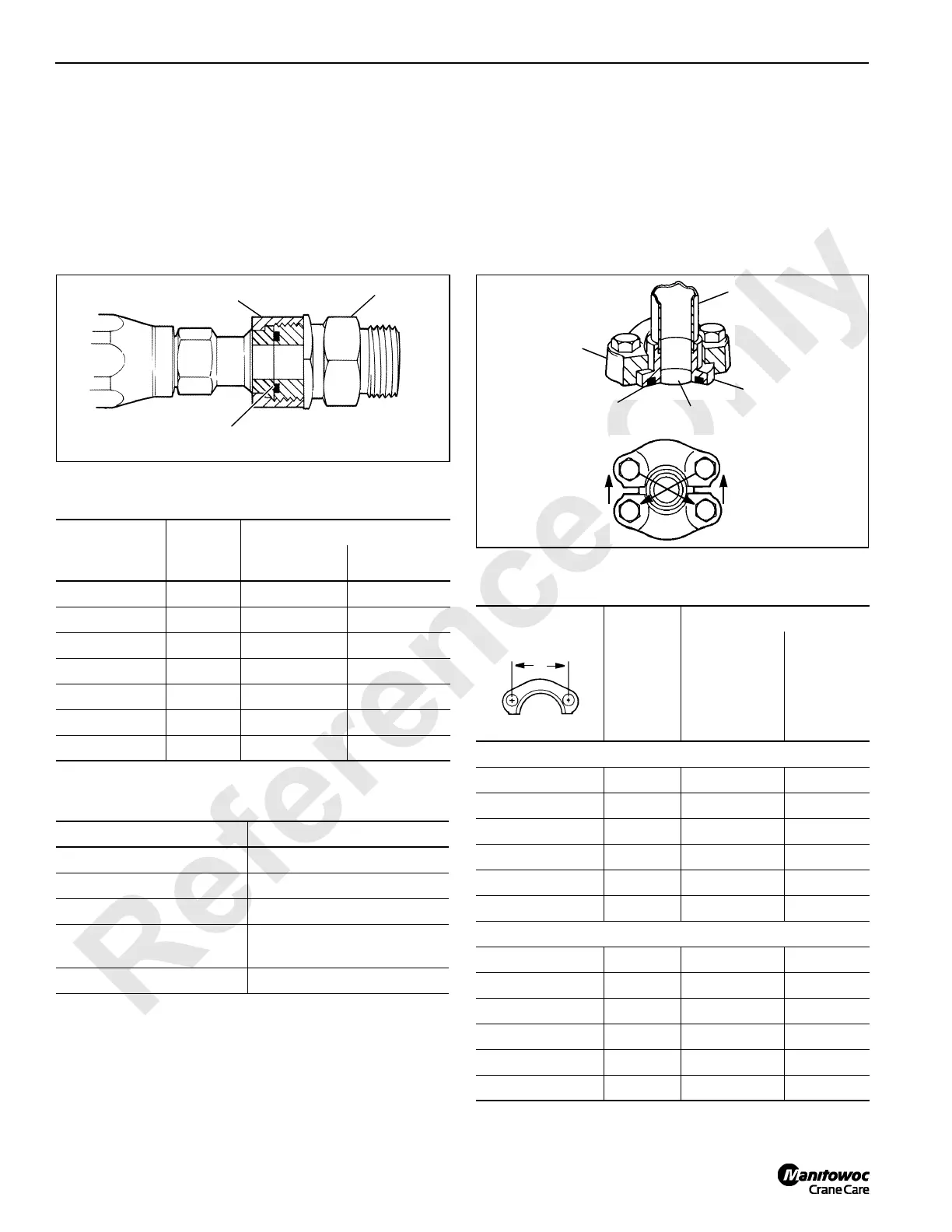

ORS Connection

NOTE: ORS is the registered trade mark for a face-type

seal manufactured by Aeroquip Corporation.

• Lubricate and install O-ring in adapter groove

(Figure 2-9).

• Lubricate threads.

• Tighten nut to torque value given in Table 2-4.

Table 2-4

ORS Assembly Torque

Table 2-5

ORS Leakage

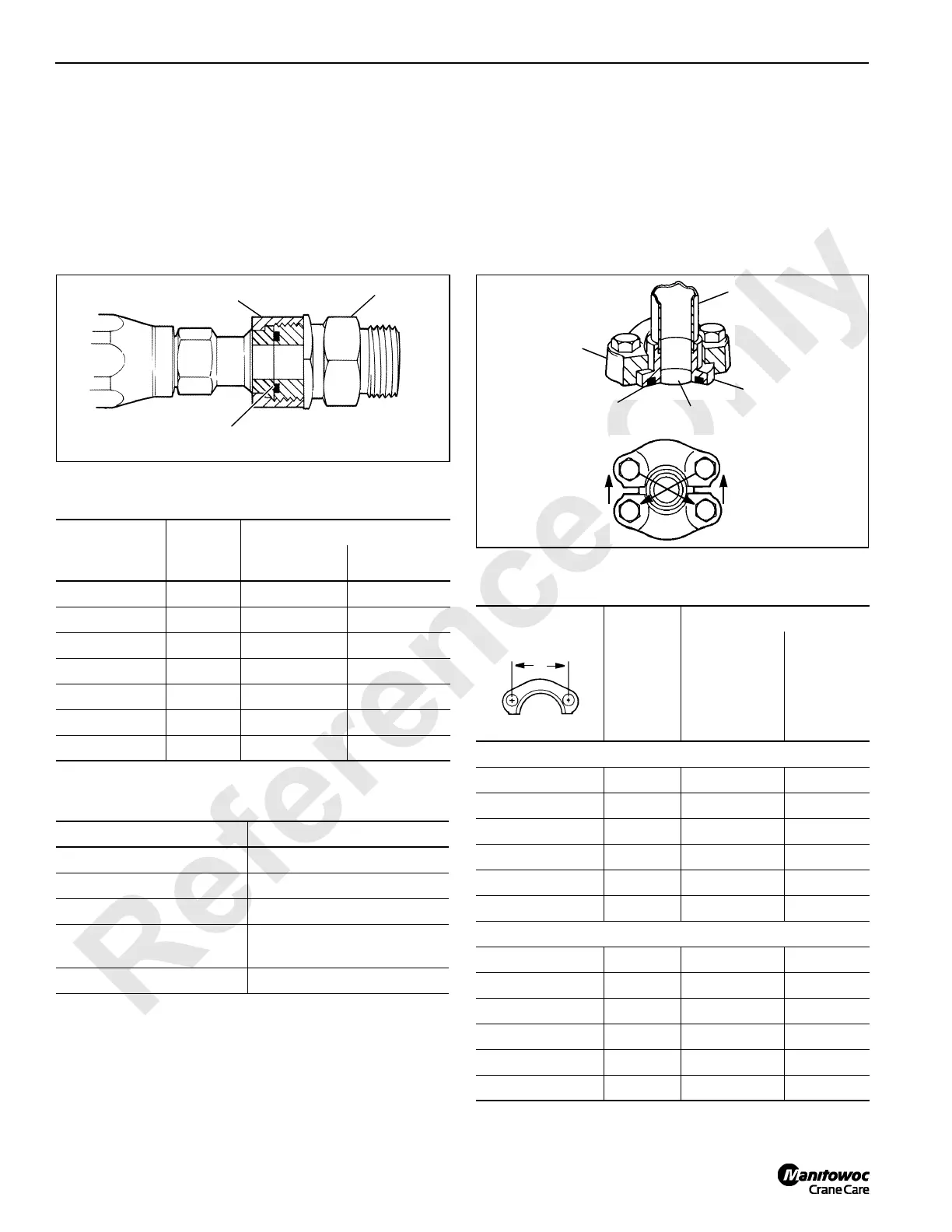

Split Flange Connection

Lubricate and install O-ring in shoulder groove (see

Figure 2-10).

1. Align shoulder with port and assemble flanges over

shoulder.

2. Bolts used must be grade-5 or better. Grade-5 bolt has

three dashes in head.

3. Snug bolts in a diagonal manner (see Figure 2-10) to 1/3

of torque given in Table 2-6.

4. Repeat step 3 to 2/3 of final torque. Repeat step 3 to

final torque.

Table 2-6

Split Flange Assembly Torque

Nut Size

inch across

flats

Fitting

Size

Torque

in-lb Nm

5/8 -04 120 – 145 14 – 16

13/16 -06 203 – 245 23 – 28

15/16 -08 380 – 470 43 – 53

1-1/8 -10 550 – 680 62 – 77

1-3/8 -12 763 – 945 86 – 107

1-5/8 -16 1110 – 1260 125 – 142

1-7/8 -20 1500 – 1680 170 – 190

Causes Cures

Nut Loose. Tighten to proper torque.

O-ring cut. Replace.

O-ring wrong size. Replace with proper size.

Sealing surfaces gouged

or scratched.

Repair if possible or replace

damaged parts.

Sealing surfaces dirty. Clean and lubricate.

Nut

Adapter

O-Ring

FIGURE 2-9

S105

"A" Dimension

(inch)

Flange

Size

Torque

in-lb Nm

Standard Pressure Series

1-1/2 -08 175 – 225 20 – 25

1-7/8 -12 225 – 350 25 – 40

2-1/16 -16 325 – 425 37 – 48

2-5/16 -20 425 – 550 48 – 62

2-3/4 -24 550 – 700 62 – 79

3-1/16 -32 650 – 800 73 – 90

High Pressure Series

1-9/16 -08 175 – 225 20 – 25

2 -12 300 – 400 34 – 45

2-1/4 -16 500 – 600 57 – 68

2-5/8 -20 750 – 900 85 – 102

3-1/8 -24 1400 – 1600 158 – 181

3-13/16 -32 2400 – 2600 271 – 294

Port

Shoulder

Flange

O-Ring

FIGURE 2-10

S104

1

2

3

4

S101

Tube

A

Loading...

Loading...