INTRODUCTION 777 SERVICE MANUAL

1-64 Published 10-01-2012, Control # 045-08

When luffing jib has been selected and confirmed at crane

mode selector, and rear drum park brake switch, located on

the front console in the operator’s cab, is placed in the off

position, the PC is prepared for any luffing commands

received from rear hoist control handle. With control handle

in the off position, the regulated voltage circuit for all luffing

commands to the PC remains open. Rear drum park brake

solenoid HS8 and rear drum band brake solenoid HS17 are

not energized and the rear hoist pump does not stroke until

the control handle is moved in either direction from off.

The description of all normal load handling operations with

the rear drum in luffing mode are identical to those described

for the front drum while performing liftcrane operations in full

power mode.

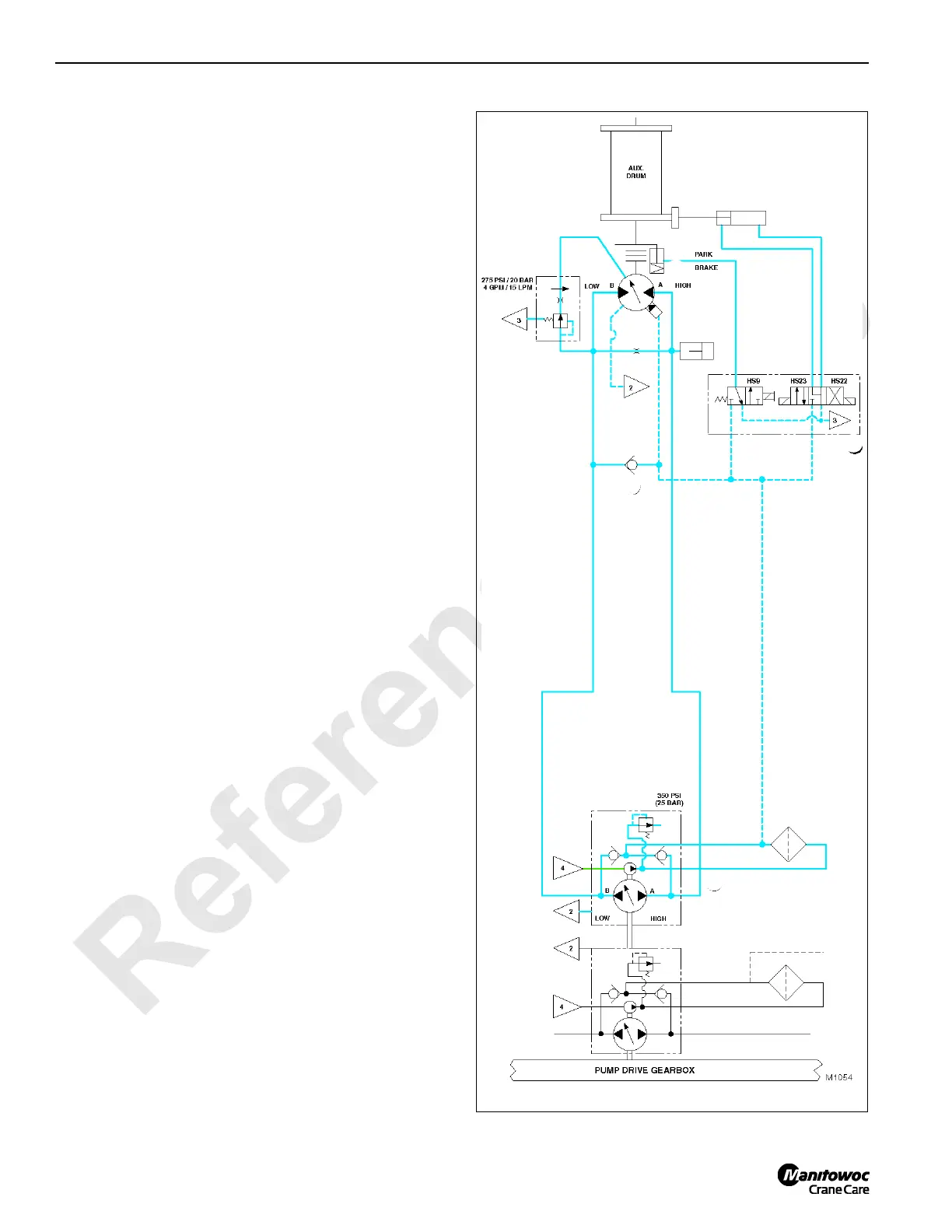

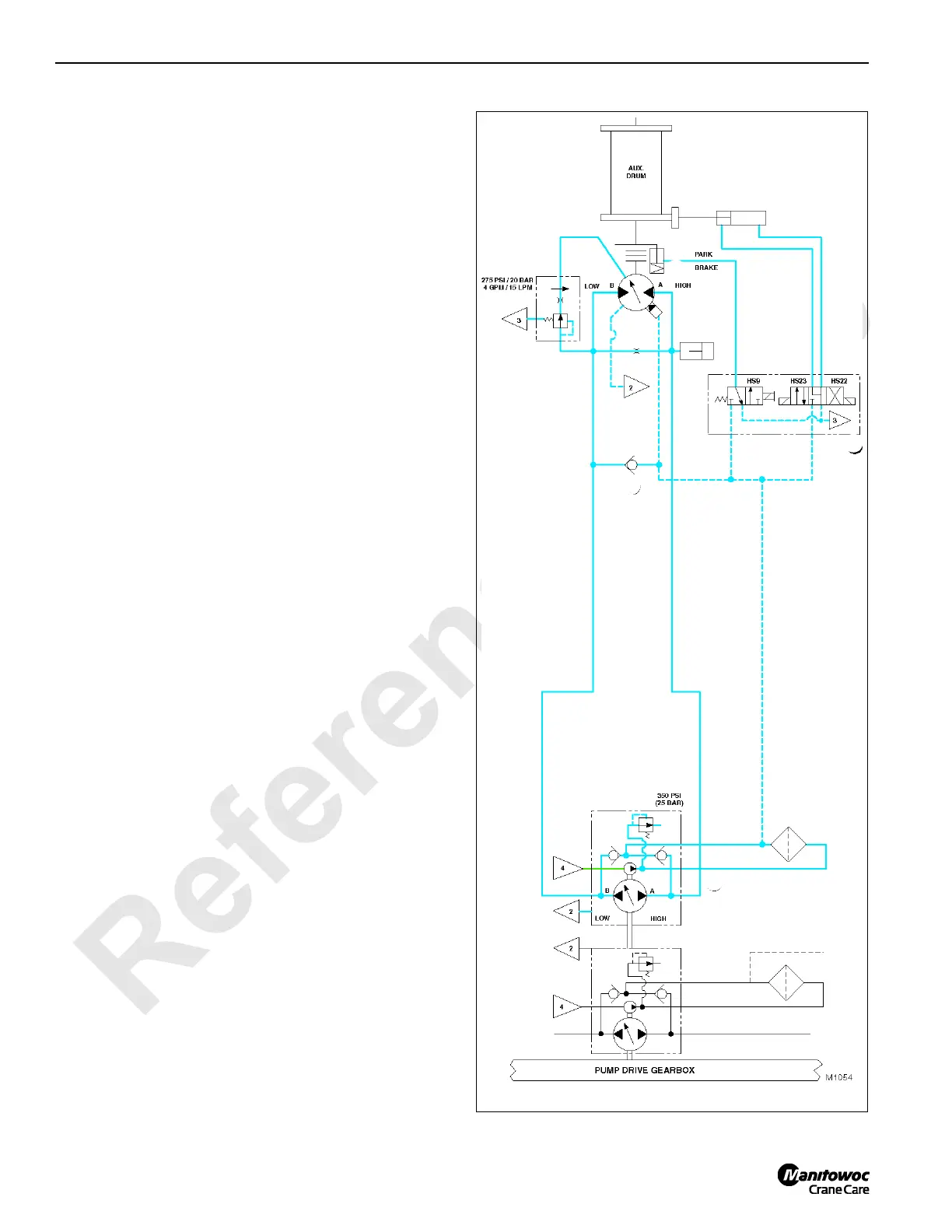

Auxiliary Hoist System

See Figures 1-46 and 1-47 for following procedures.

If crane has an auxiliary hoist, its drum is located in boom

butt.

Unlike all other system pumps, displacement in the auxiliary

hoist pump is controlled by both coils in the EDC valve and

function only with straight current rather than straight and

reverse polarity.

If auxiliary hoist charge pressure is lost for any reason,

auxiliary hoist park brake will apply to stop the hoist since the

brake is directly sourced from this pressure.

Like all other crane systems, the hydraulic connection

between auxiliary hoist pump and auxiliary hoist motor forms

a simple closed-loop circuit. Make-up oil from auxiliary hoist

charge pump replaces oil in the system that is primarily

displaced due to internal leakage of the pump and motor

assemblies.

If auxiliary drum park switch, located on the front console in

the operator’s cab, is placed in the on position, the auxiliary

hoist control handle circuit to the PC opens and does not

complete the circuit from the PC to auxiliary drum brake

hydraulic solenoid HS9. Because these circuits are open,

auxiliary drum park brake remains applied and auxiliary hoist

pump will not stroke in response to movement of auxiliary

hoist control handle.

The hydraulic actuation of auxiliary drum park brake is

spring-applied/pressure released and controlled

automatically by the PC in conjunction with movement of

auxiliary hoist control handle. Release of brake is with

auxiliary charge pressure and from low pressure side of its

closed-loop circuit through check valve.

When releasing brake, charge pressure is directed into

brake valve chamber through HS9. If the charge pressure

drops to below 250 psi (17 bar), brake application begins,

and if the pressure continues to drop to approximately 165

psi (11 bar) or lower, the brake is fully applied.

FIGURE 1-46

Loading...

Loading...