Manitowoc Published 10-01-2012, Control # 045-08 5-9

777 SERVICE MANUAL HOISTS

5

Disconnecting Block-Up Limit Control

See Figures 5-6 and 5-7 for identification of the electric cords

and shorting plugs.

Shorting plug SP1 is provided on the left front corner of

rotating bed so the block-up limit controls can be

disconnected for the following reasons:

• Crane setup and rigging.

• Maintenance.

• Operations not requiring use of a block-up limit control

(clamshell and drag-line).

To disconnect the block-up limit controls, proceed as follows:

1. Disconnect electric cord (C2) from cable reel (CR1).

2. Remove the closure cap from shorting plug (SP1).

3. Connect electric cord (C2) to shorting plug (SP1).

4. Reverse the steps to reconnect the block-up limit

control.

Removing Jib or Boom Point

See Figures 5-6 and 5-7 for identification of the electric cords

and shorting plugs.

The junction boxes on the boom and luffing jib points have

shorting plugs.

If the fixed jib point, upper boom point, or luffing jib point has

a block-up limit switch, the electric cord from the limit switch

must be connected to the proper shorting plug when the

corresponding attachment is removed.

Failing to perform this step will prevent the load drum from

hoisting and the boom from lowering. Also the operating limit

alert will come on.

Be sure to reconnect electric cord to proper block-up

limit switch when corresponding attachment is

reinstalled.

Maintenance

See Figure 5-8 for following procedure

Inspect and test the block-up limit controls weekly or every

40 hours of operation, as follows:

1. Lower the boom onto blocking at ground level and

carefully inspect the following items:

a. Inspect each limit switch lever and actuating lever

for freedom of movement. Apply one-half shot of

grease to the fitting on the actuating lever. Wipe

away any excess grease.

b. Inspect each weight for freedom of movement on

the load line.

c. Inspect each weight, each chain, each shackle and

each connecting pin for excessive or abnormal

wear. Make sure cotter pins for shackles are

installed and spread.

d. Inspect the entire length of electric cords for

damage.

e. Check that the electric cords are clear of all moving

parts on the boom and jib and that the cords are

securely fastened to the boom and jib with metal

straps.

f. Check that all plugs are securely fastened.

2. Test the block-up limit controls for proper operation

using either of the following methods:

a. BOOM LOWERED: Manually lift each weight —

one at a time — while the engine is running. The

load drum should not operate in the hoist direction

and the boom/luffing hoist should not operate in the

lower direction.

b. BOOM RAISED: Slowly hoist each load block and

weight ball — one at a time — against the weight.

When the chain goes slack, the corresponding load

drum should stop hoisting and the boom/luffing hoist

should not operate in the lower direction.

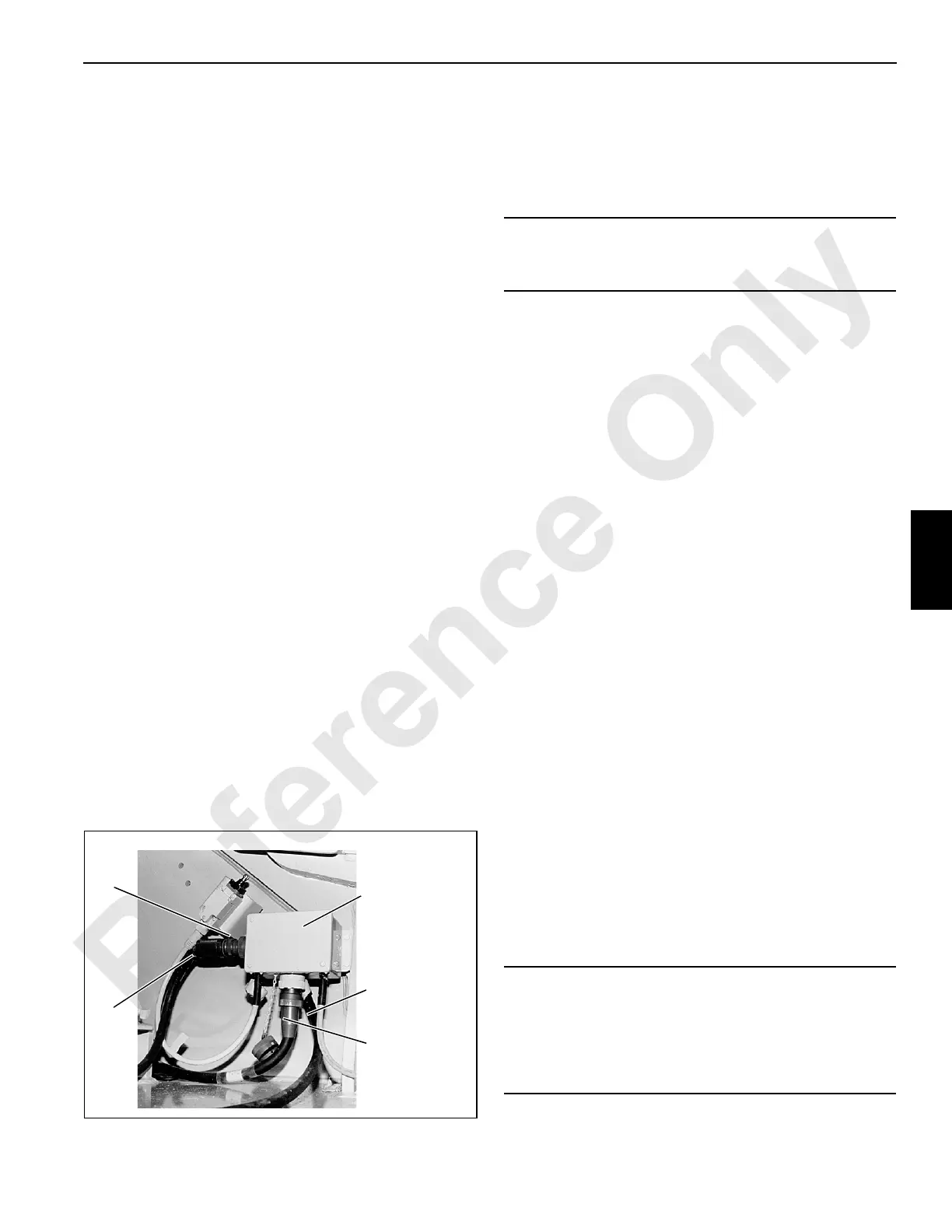

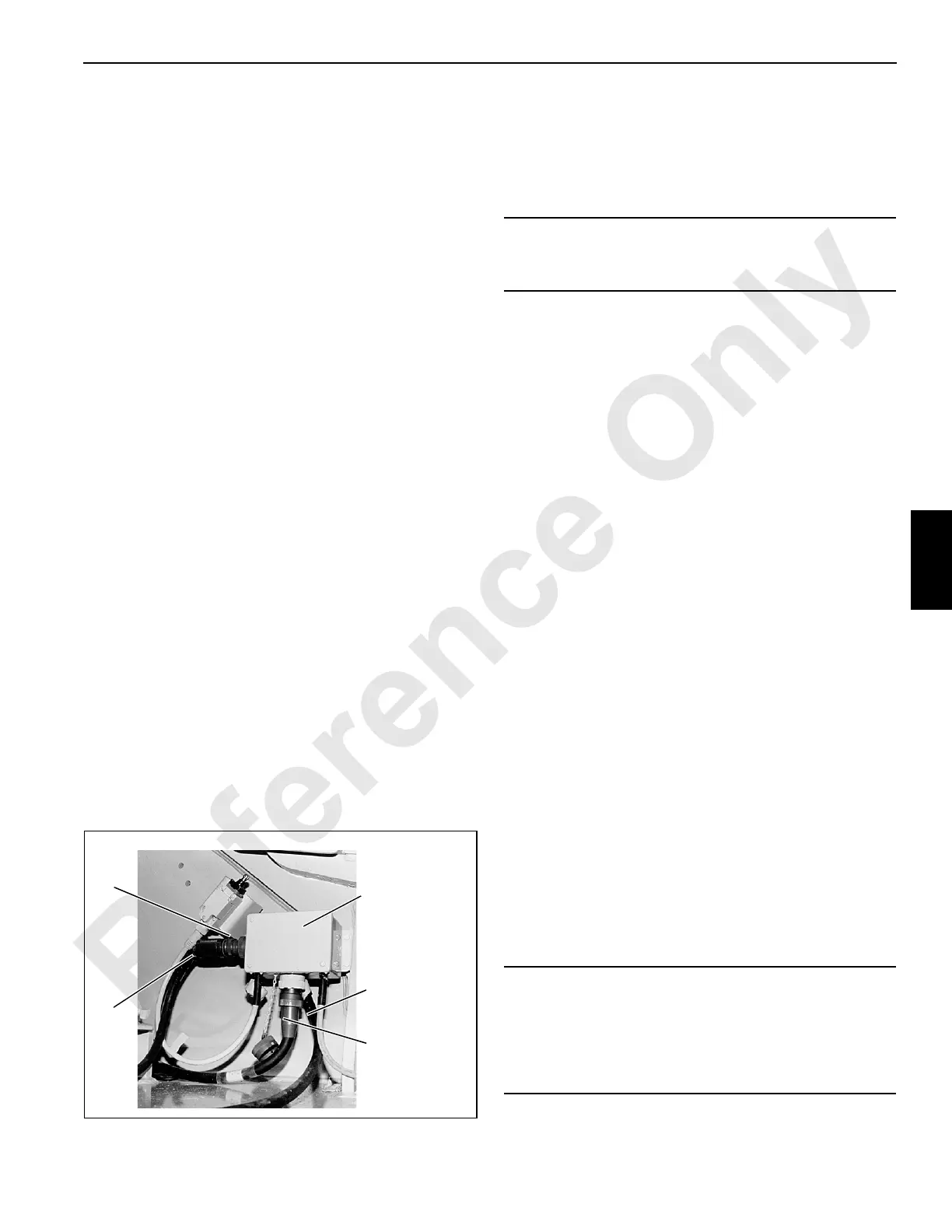

FIGURE 5-7

P440

JB1

Boom Junction Box

C2

Electrical Cord

To Boom Angle

Indicator

on Rotating Bed

SP1

C1

CAUTION

Do not operate crane until cause for improper operation

and all hazardous conditions are found and corrected.

CAUTION

Use extreme care when testing block-up limit controls

when boom is raised. If block-up limit control fails to stop

load, immediately stop load by moving drum control

handle to off or by applying drum working brake;

otherwise, two-blocking may occur.

Loading...

Loading...