INTRODUCTION 777 SERVICE MANUAL

1-26 Published 10-01-2012, Control # 045-08

Brake Release System

The load drum, travel, swing, and auxiliary hoist disc brakes

are hydraulically released. The load drums also have a

hydraulically released band-type brake.

Hydraulically Released

The PC automatically controls release of the load drum,

travel, and auxiliary hoist brakes once the selected system’s

park switch is placed in the off position and its control handle

is moved from off. The release of the swing brake is

controlled independently when the operator places the swing

brake switch in the off position.

When the rear load drum, travel, or swing, brake hydraulic

solenoid is energized, the applicable valve shifts to block the

tank port and to supply charge pressure from the rear drum

charge pump to the appropriate brake. The brake then

releases. The front load drum brake or auxiliary hoist is

released by pressure from their own system charge pump.

When a brake solenoid is de-energized, the valve closes to

block the pump port and to vent pressure in the brake to

tank. The brake then spring-applies.

If brake pressure or electric current is lost for any reason

during operation, the brakes will spring-apply to stop the

function.

Working Brakes (with free fall)

See Figure 1-17 for following procedures.

When in free fall, the operator can control the lowering of a

load by applying a linear force to the working brake pedal (4)

to control pressure to the working brake (band brake

cylinder) of the selected drum. The working brake pedal can

be described as a reverse modulating valve operating

between the system pressure of 2500 psi (no foot pressure

applied and in unlatched position) to 50 psi (maximum

applied foot pressure or in latched position).

The brake pressure is in direct proportion to brake pedal

movement. When applying manual force, with the foot to the

working brake pedal, a proportional amount of hydraulic

pressure is released from the band brake cylinder through

the working brake valve to tank, causing the release springs

of the cylinder to expand and apply brake band pressure

against the drum. When pedal is fully applied or latched full

brake application is obtained. Conversely, by releasing

manual force to the brake pedal, a proportional amount of

hydraulic pressure is applied to the brake band cylinder

causing the release springs to compress and remove brake

band pressure to the drum. When pedal is fully released, the

release spring is fully compressed, allowing the band brake

to be fully released.

The working brake section of the auxiliary systems pump

provides an adequate hydraulic fluid supply at a maximum

system pressure of 2,500 psi for band brake actuation. The

system flow pressure is controlled by relief valve preset to

2,500 psi (175 bar) and is regulated in pressure operating

range of 50 to 2,500 psi as it passes through the reverse

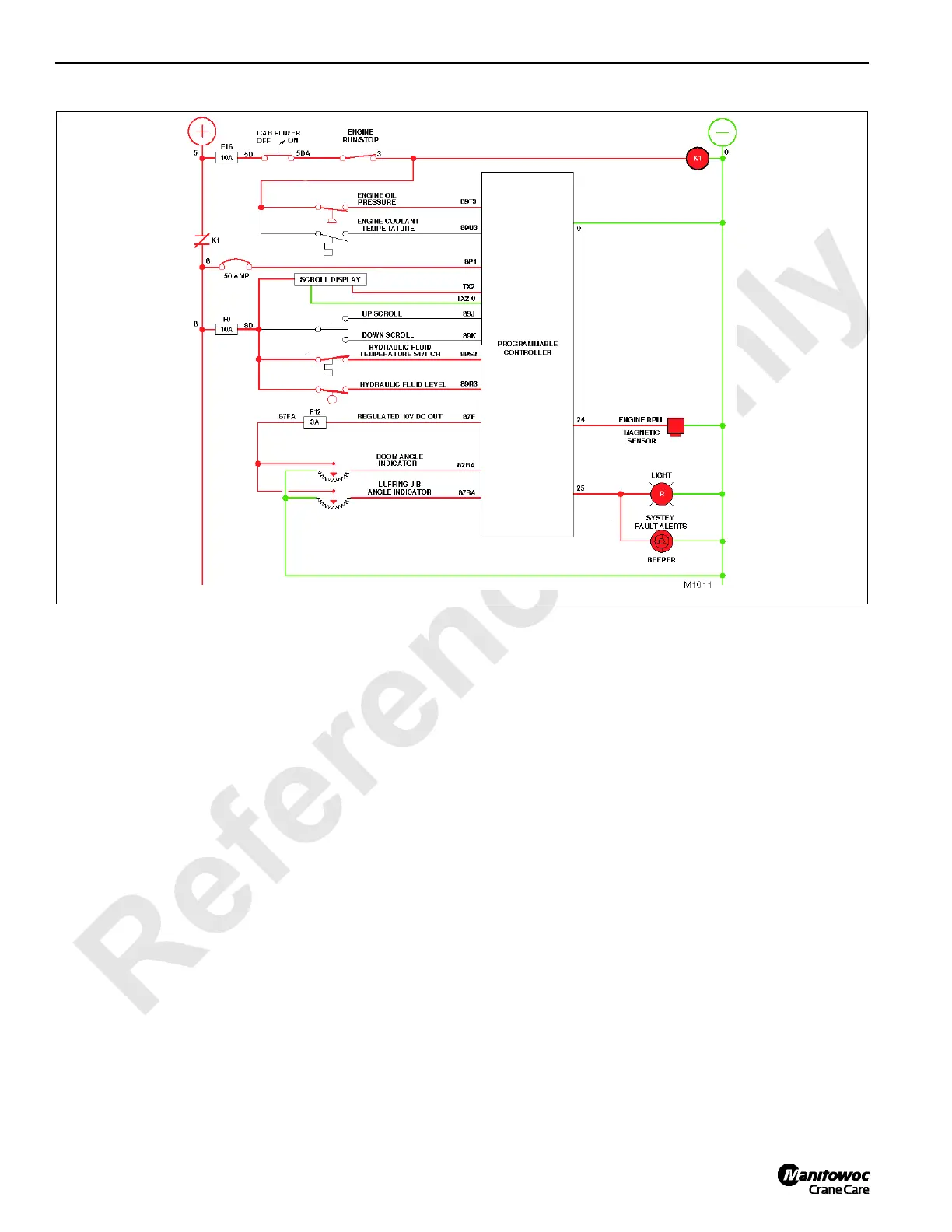

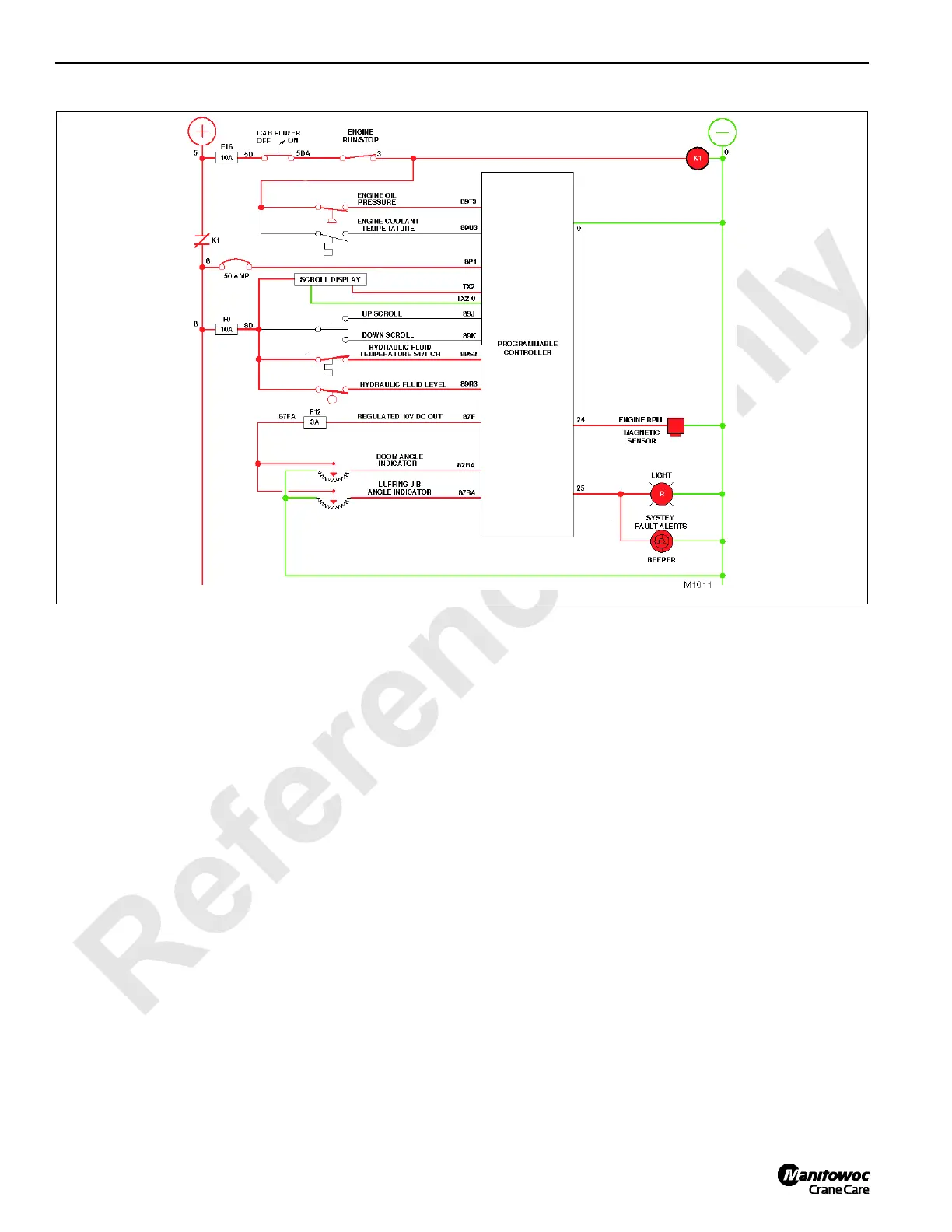

FIGURE 1-16

Loading...

Loading...