BOOM 777 SERVICE MANUAL

4-20 Published 10-01-2012, Control # 045-08

End Lacing Replacement on an Insert (Angle and

Tubular Chords)

1. This procedure can be used for replacing the end lacing

on a top or butt lattice section with angle chords.

2. Pin another lattice section to the end of the section being

repaired. The connectors should be wedged over to

ensure no lateral movement.

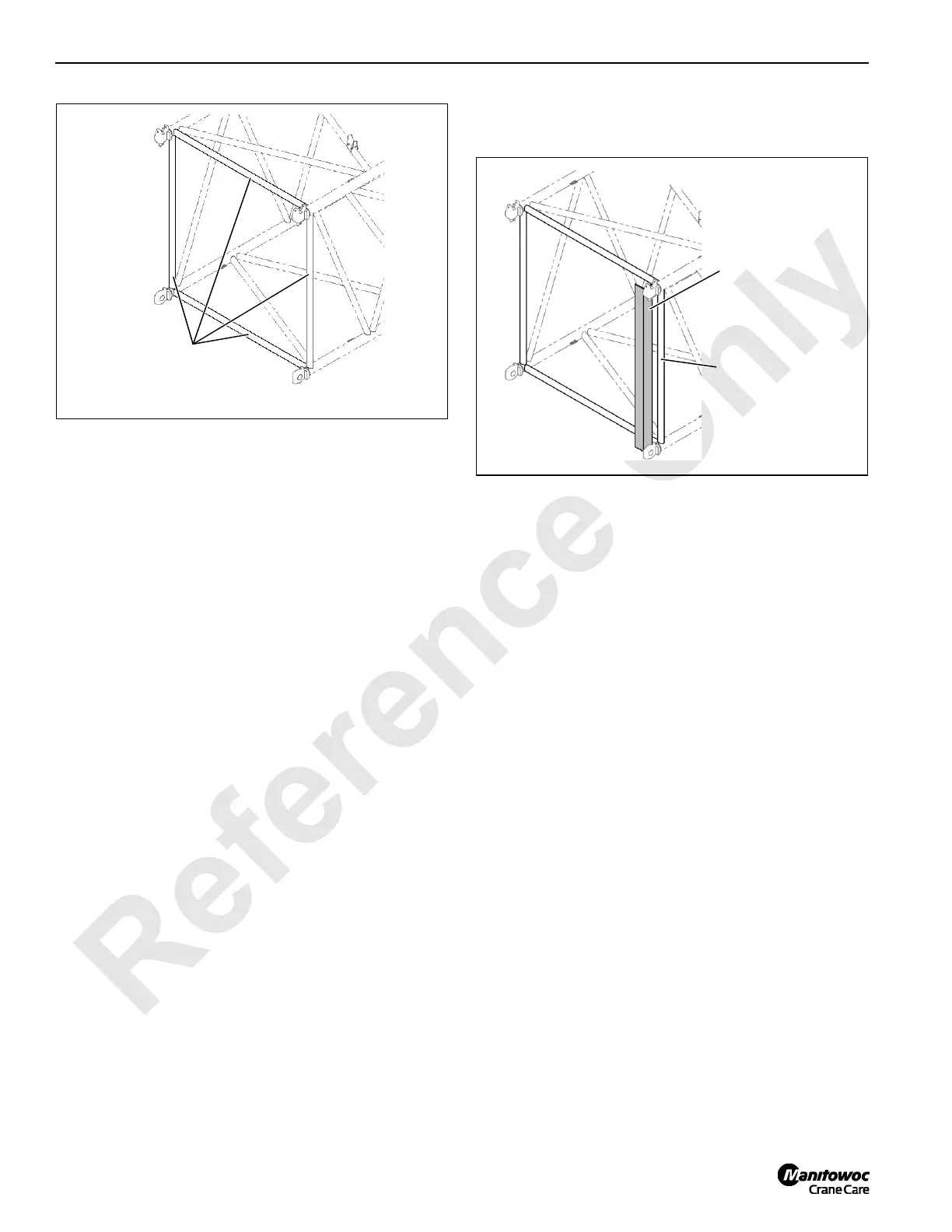

3. If another lattice section is not available, tack weld a

temporary brace to the connectors parallel to the

damaged lacing (see Figure 4-23).

Care must be taken to not damage the machined

surface of the connector.

• The temporary brace will need to be strong enough

to not allow the connectors to move in or out. A

minimum 4 in (102 mm) by 4 in (102 mm) by 3/8 in

(10 mm) angle is required.

• The connectors shall be preheated to a minimum of

150°F (66° C) before tacking.

• Use 3/32 in (2,5 mm) E9018-M stick electrode for

tacking the temporary brace.

• Tacks shall be 1 to 1-1/2 in (25 to 38 mm) long. The

tacks shall be sound with no undercut to the

connector.

• Do not tack to any machined surfaces.

4. Use the same process for removing and replacing lacing

as specified in Lacing Replacement on page page 4-18.

5. Remove the temporary bracing without damaging the

connectors.

Do not cut or gouge the connector. Stop all work if

connector is damaged and contact Manitowoc

Crane Care.

6. Send all completed inspection reports to Manitowoc

Crane Care. Digital photographs should be taken and

sent with the inspection reports.

End Lacing Replacement on Tapered Sections

(Tubular Chords)

1. This procedure applies specifically to tapered lattice

sections that have tubular chords. Examples: tops, butts,

and transition inserts.

2. The replacement end lacing cannot be installed into a

tapered lattice section due to clearance issues with the

connector. For this reason, the connectors cannot be

restrained to install the replacement lacing. Therefore

the section being repaired must be pinned to another

section.

3. Perform Lacing Replacement steps 1-7 on page

page 4-18. Do not replace more than one lacing at a

time.

4. The lacing must be installed and not tack welded.

Safety Note: Make sure the lacing cannot fall out and

injure someone.

5. Pin another lattice section to the end of the section being

repaired. The connectors should be wedged to prevent

lateral movement of the sections.

6. Only after the section is pinned to another section can

the replacement end lacing be tack welded into position.

7. Perform Lacing Replacement steps 8-14 starting on

page page 4-18.

8. Send all completed inspection reports to Manitowoc

Crane Care. Digital photographs should be taken and

sent with the inspection reports.

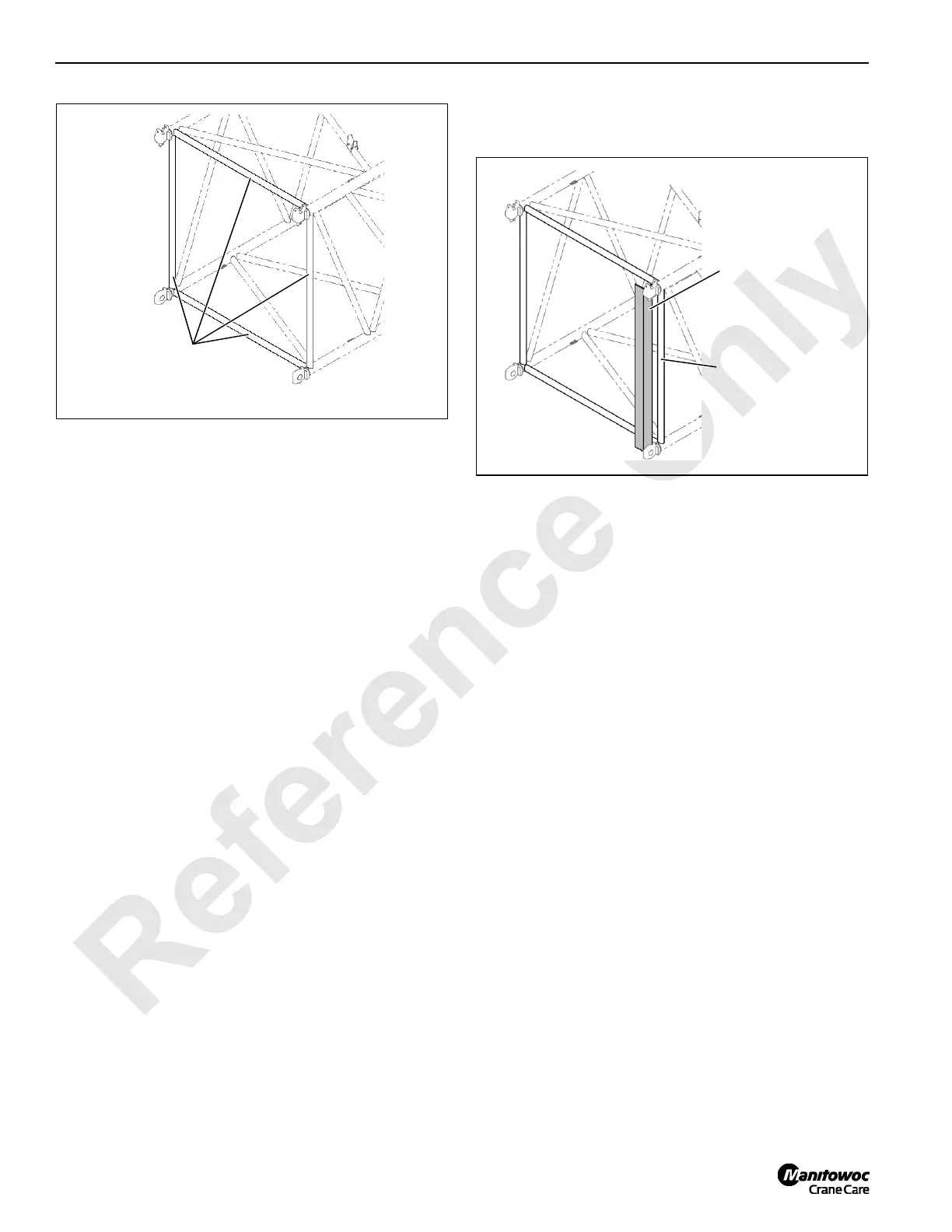

FIGURE 4-22

End Lacings

FIGURE 4-23

EXAMPLE

Damaged

End Lacings

Brace Tack Welded to

Connectors Parallel to

Damaged End Lacing

Loading...

Loading...