Manitowoc Published 10-01-2012, Control # 045-08 1-59

777 SERVICE MANUAL INTRODUCTION

1

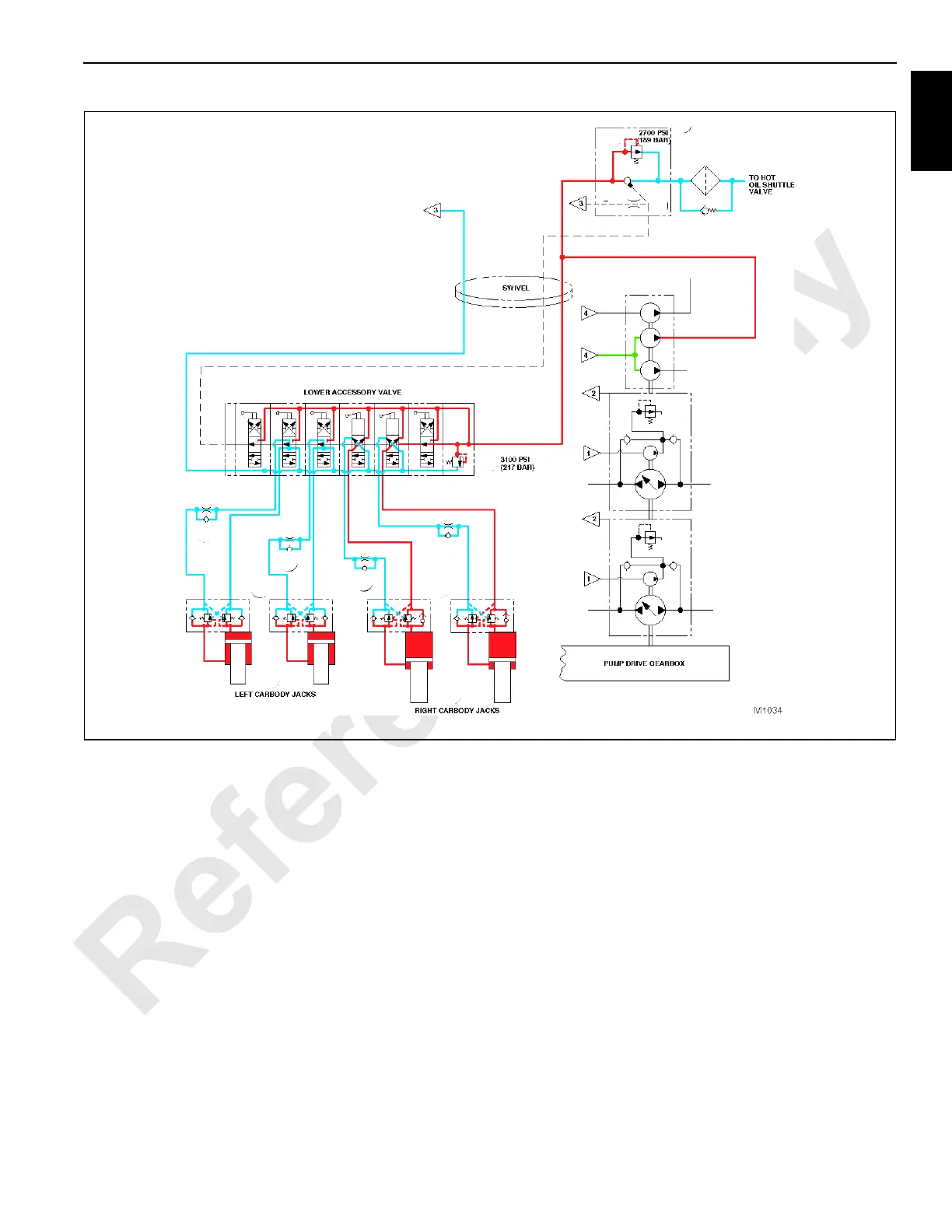

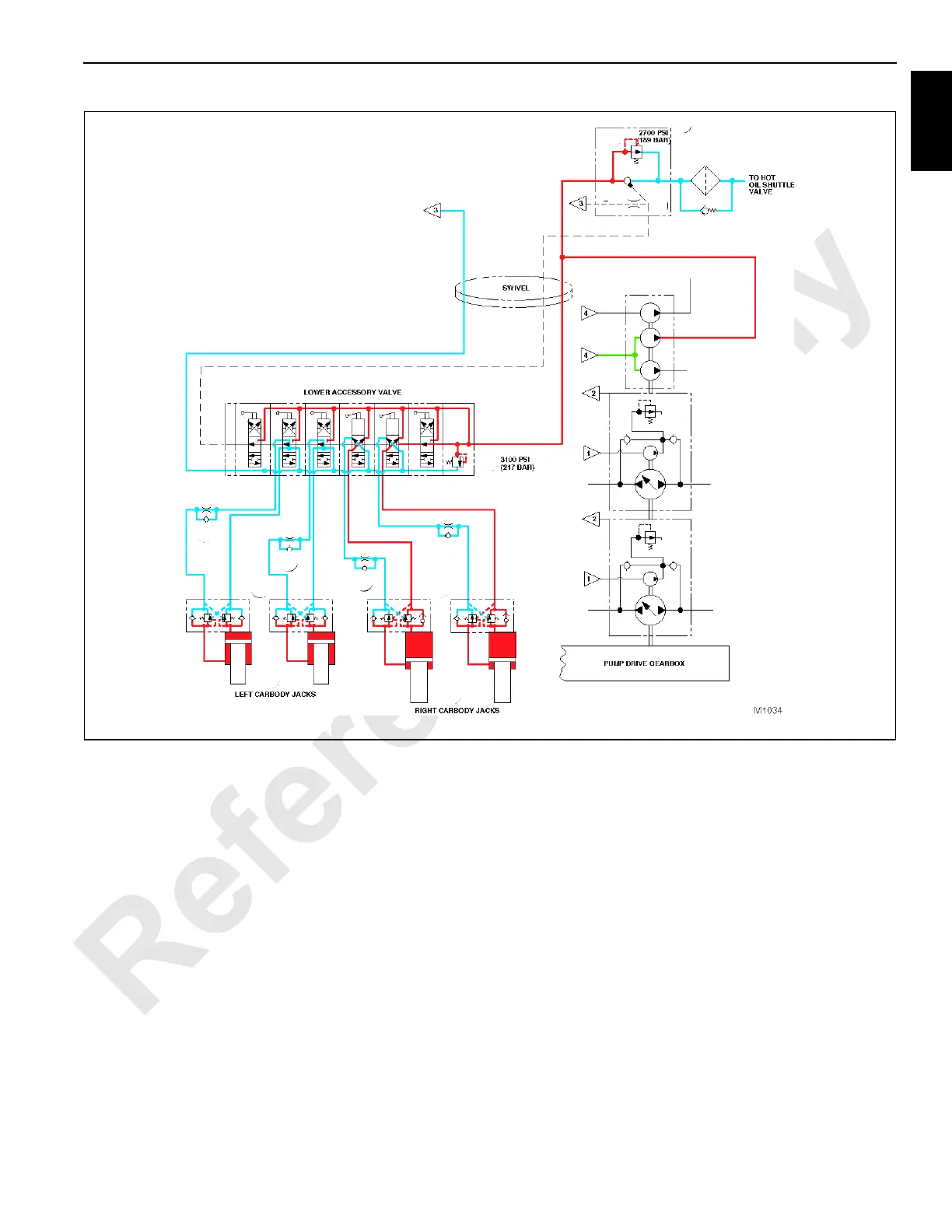

Jacking Cylinder Retract

See Figure 1-43 for following procedures.

When a jacking cylinder control valve handle is held in the

retract position, moving the lever upward on lower accessory

valve, the valve section shifts to direct oil flow from the setup

pump section of accessory pump and into relief valve (preset

to 3,100 psi / 214 bar) section of lower accessory valve. Note

the system pump flow pressure is limited by relief valve in

system disable valve which is preset to approximately 2,700

psi (186 bar).

The oil exits the desired function valve section of lower

accessory valve and flows through the restraining section of

flow control valve that controls the speed at which the

cylinder retracts by limiting the velocity of oil flow before

passing through the free-flow poppet (check valve) section of

counterbalance valve. The oil then proceeds into the rod end

of carbody jacking cylinder.

NOTE: Hydraulic pressure entrapped by the cylinder

counterbalance valve at the head end of the

carbody jacking cylinder supports the weight and

gravitational force of the carbody.

Oil exhausting from the head end of the carbody jacking

cylinder is blocked by the free-flow poppet (check valve)

section of counterbalance valve and flows through the

valve’s load restraining section which is preset to 3,500 psi

(241 bar). The counterbalance valve serves as a

deceleration control and functions with a 3:1 pilot ratio of the

pressure setting, permitting the valve to open when the

pressure in the rod end of the cylinder is approximately 1,170

psi (81 bar). The restraining section of counterbalance valve

opens which controls oil flow out of the carbody jacking

cylinder to lower accessory valve. The oil leaving the lower

accessory valve returns to tank.

FIGURE 1-41

Loading...

Loading...