Manitowoc Published 10-01-2012, Control # 045-08 1-7

777 SERVICE MANUAL INTRODUCTION

1

GENERAL OPERATION

Operating System

A safety mechanism that prevents systems operation until

the cab seat is occupied by the operator, governs operation

of the EPIC® Hydraulic-Series crane. When the engine is

running and the operator is not seated, the seat switch circuit

is open, all control handles are inoperable, all park brakes

are applied (including free fall) and travel detent systems are

turned off. The display indicates an operating limit message

FUNCTION IS PARKED.

Hydraulic Components

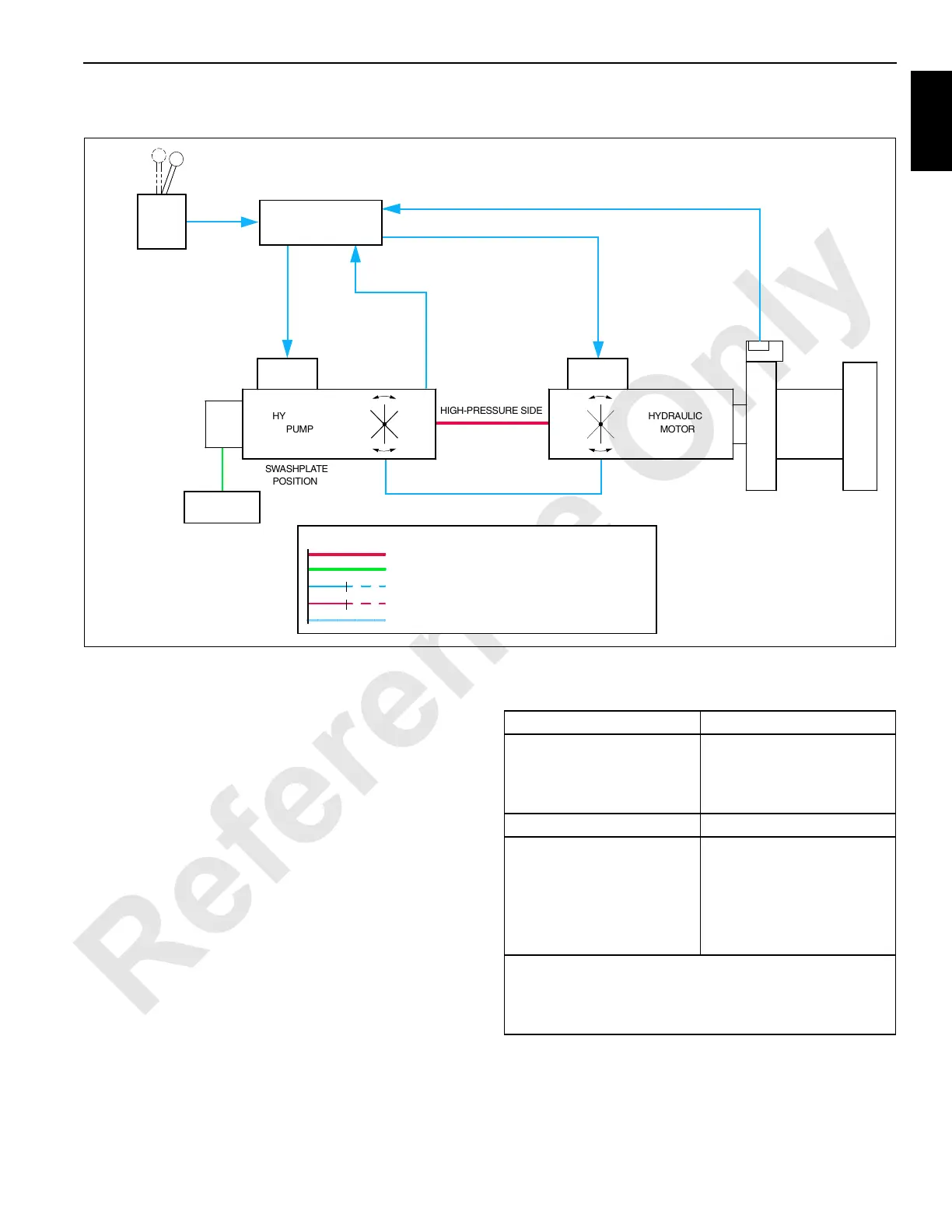

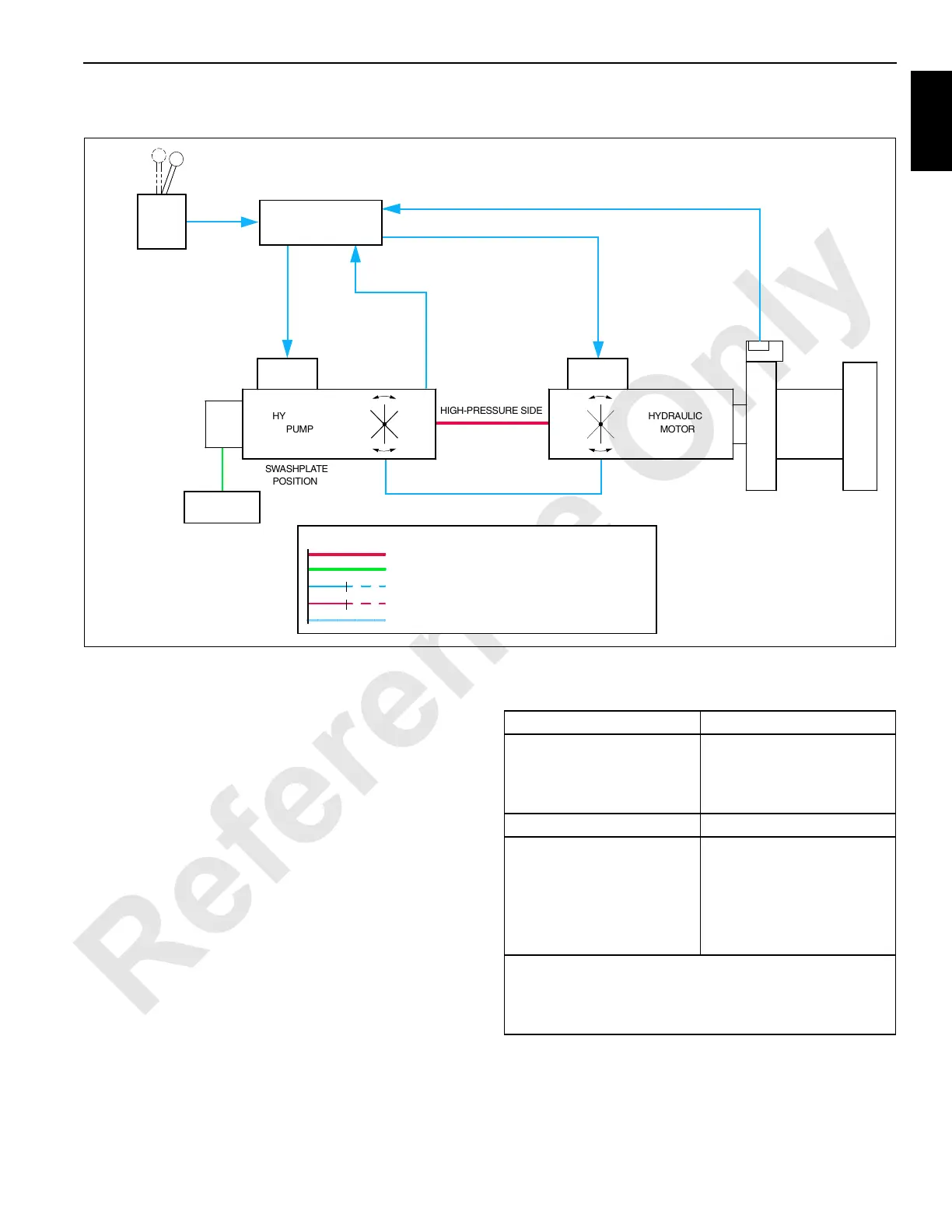

See Figure 1-4 for following procedure.

Each system is controlled through a programmable

controller (PC) and is independently powered by a hydraulic

pump and an actuator in a closed-loop hydraulic system.

See Table 1-1 for the types of pump and actuator in each

system, and to Sundstrand Series 90 Service Manual for an

operational description of a hydrostatic transmission.

In a closed-loop hydraulic system, the oil output from the

system pump drives an actuator, and then returns directly to

the pump’s input instead of returning to the crane’s hydraulic

tank.

Table 1-1

Pump and Actuator Description

A gear pump on each system pump supplies oil at charge

pressure to maintain the closed-loop system’s minimum

pressure requirements. This oil is also used to regulate the

oil flow from the pump by moving a swashplate

servomechanism within the pump in response to an external

electric displacement control (EDC).

FIGURE 1-4

COMMAND

SIGNAL

PILOT

CONTROL

PRESSURE

PCP

EDC

LINE LEGEND (FOR ALL SCHEMATICS)

CASE RETURN PRESSURE HYDRAULIC

CONTROL OR PILOT PRESSURE HYDRAULIC

LOW-PRESSURE HYDRAULIC, SIGNAL ELECTRICAL

NEGATIVE ELECTRICAL (GROUND), SUCTION MANAFOLD

HIGH-PRESSURE HYDRAULIC, POSITIVE ELECTRICAL

0000000000000000000000000000000000000000000000000000

POSITION

SWASHPLATE

HIGH-PRESSURE SIDE

MOTOR

HYDRAULIC

PUMP

HYDRAULIC

DRUM

CONTROLLER (PC)

MANIFOLD

SUCTION

PUMP

CHARGE

LOW-PRESSURE SIDE

FEEDBACK

FEEDBACK

PRESSURE

(MOTOR STROKE)

CONTROL SIGNAL

(PUMP STROKE)

CONTROL SIGNAL

CONTROL

DISPLACEMENT

ELECTRONIC

HANDLE

CONTROL

PIPING

HYDRAULIC

PROGRAMMABLE

HANDLE

RF-01

SPEED SENSOR

Pump System Description

Front and Rear Hoists (Load

Drums), Auxiliary Hoist,

Boom, Swing, and Travel.

Accessory

Variable Displacement, Axial

Piston

Fixed Displacement, Gear

Actuator System Description

Front and Rear Hoists (Load

Drums), Auxiliary Hoist,

Travel.

Boom Hoist

Swing

Variable Displacement, Bent-

Axial Piston Motor

Two Bi-Directional Cylinders

Fixed Displacement, Axial/

Piston Motor

Travel motors are normally in minimum displacement position

(low torque, high speed).

Travel motors start to shift to maximum displacement position

at approximately 3,500 psi (241 bar) (high torque, low speed).

Loading...

Loading...