BOOM 777 SERVICE MANUAL

4-4 Published 10-01-2012, Control # 045-08

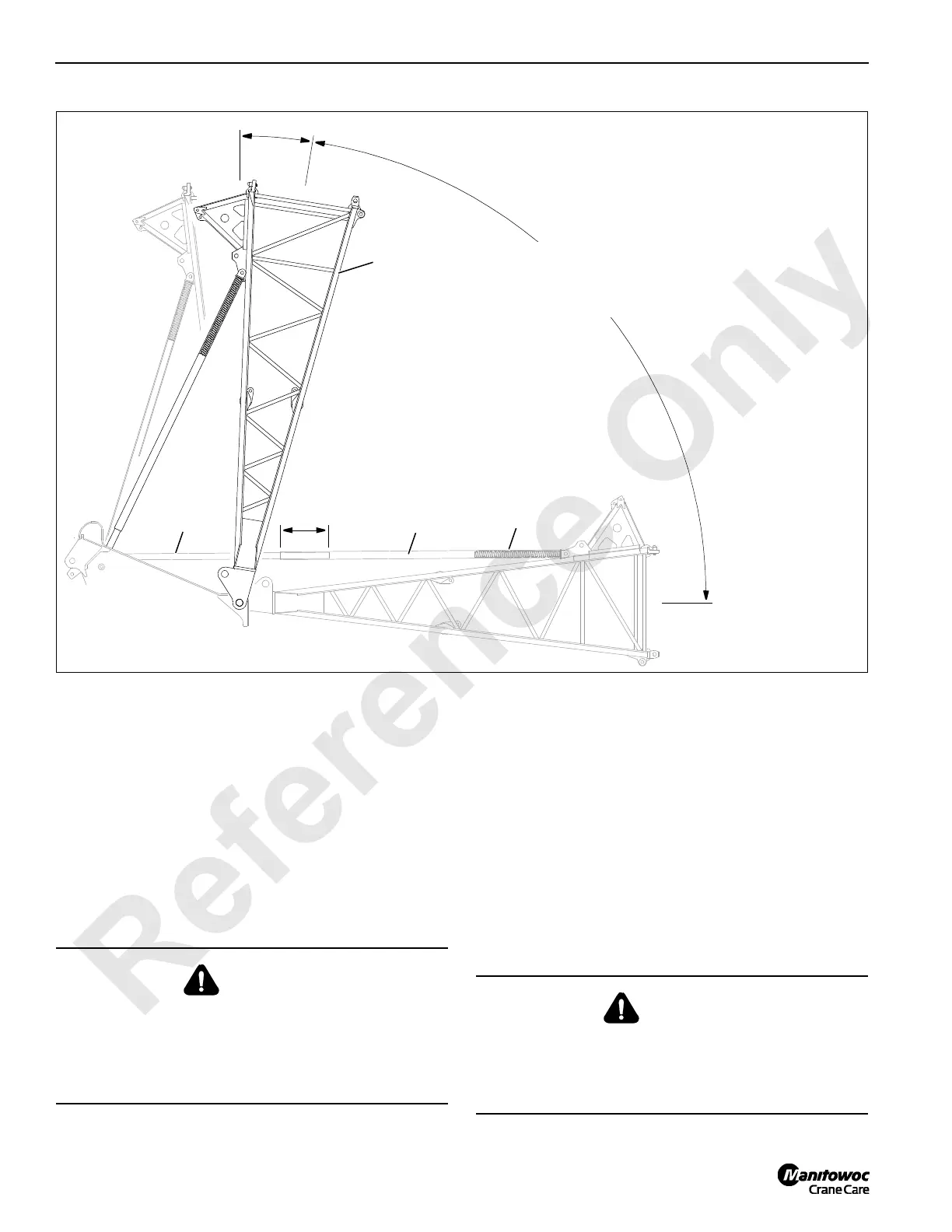

PHYSICAL BOOM STOP

The physical boom stop assembly (Figure 4-3) serves the

following functions:

• Assist in stopping the boom smoothly at any angle

above 81°.

• Assist in preventing the boom rigging from pulling the

boom back when traveling or setting loads with the

boom at any angle above 81°.

• Assist in moving the boom forward when lowering the

boom from any angle above 81°.

• Provide a physical stop at 90°.

Operation

See Figure 4-3 for following procedure.

1. When the boom is raised to 81°, the springs in the boom

stop tube begin to compress.

2. As the boom is raised higher, spring compression

increases to exert greater force against the boom.

3. If for any reason the boom is raised to 90°, the boom

stop springs will fully compress to provide a physical

stop.

Removal

Normally, the boom stop tubes are not removed unless they

need repair or replacement.

FIGURE 4-3

A991

81°

81° Start of

Spring Cushion.

Solid at 90°

32 inch

Overlap

Boom Stop

Upper Tube

Spring

Boom Stop

Lower Tube

Use care when handling boom

stop tubes. Lower tube is not

retained in upper tube.

Boom Butt

Shipping

Position

90°

WARNING

Falling Load Hazard!

Physical boom stop must be installed for all crane

operations. Physical boom stop does not automatically

stop boom at maximum operating angle. Automatic boom

stop must be installed and properly adjusted.

WARNING

Falling Load Hazard!

Use care if boom stop tubes are removed for any reason.

Lower tube is not retained by upper tube and they may

separate when detached.

Loading...

Loading...