TROUBLESHOOTING 777 SERVICE MANUAL

10-36 Published 10-01-2012, Control # 045-08

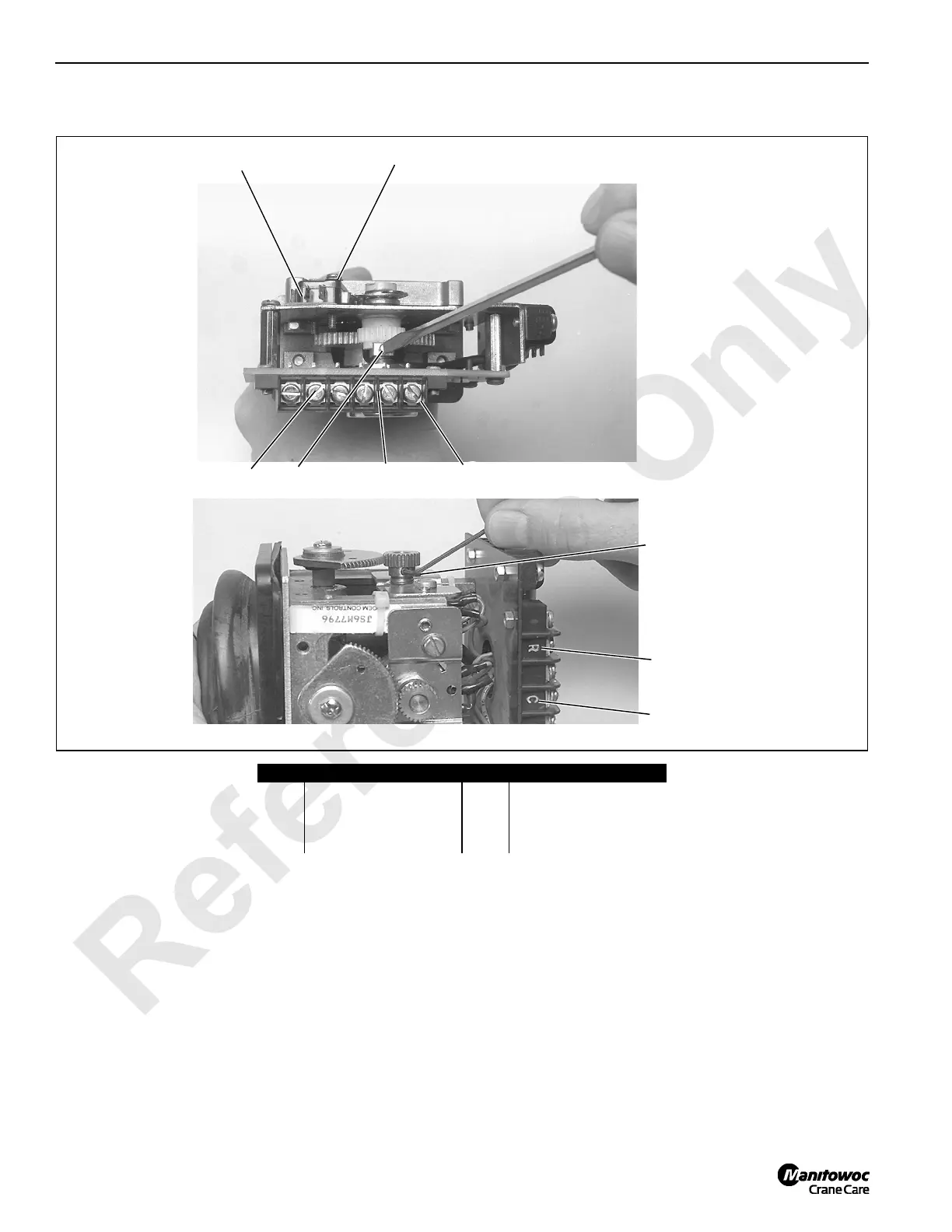

Test 8 – Adjusting the Control Handle Potentiometer

A reaction of a crane system function in relation to hand

control movement may indicate a misalignment of the handle

potentiometer. Adjusting a single axis controller (crawler and

load drum handles) or double axis boom/swing handle

requires aligning the hand lever assembly and the

potentiometer in the neutral position. Neutral is the position

at which 5 volts DC is present from the potentiometer.

With engine off, connect a jumper wire between the normally

open (N/O) terminal on the neutral switch and terminal C on

the handle terminal block. Connect the positive lead of a

digital multimeter to terminal C and the negative lead to a

grounded contact.

For single axis controller adjustment, fully loosen the slotted

set screw with a screwdriver and allow the hand lever to

return to its inactivated position. Retighten the set screw and

move the hand lever until a reading of 5 volts DC is obtained

on the digital multimeter. Keeping the hand lever in the 5 volt

DC position, fully loosen the set screw, allow the hand lever

to return to its inactivated position, and retighten the set

screw.

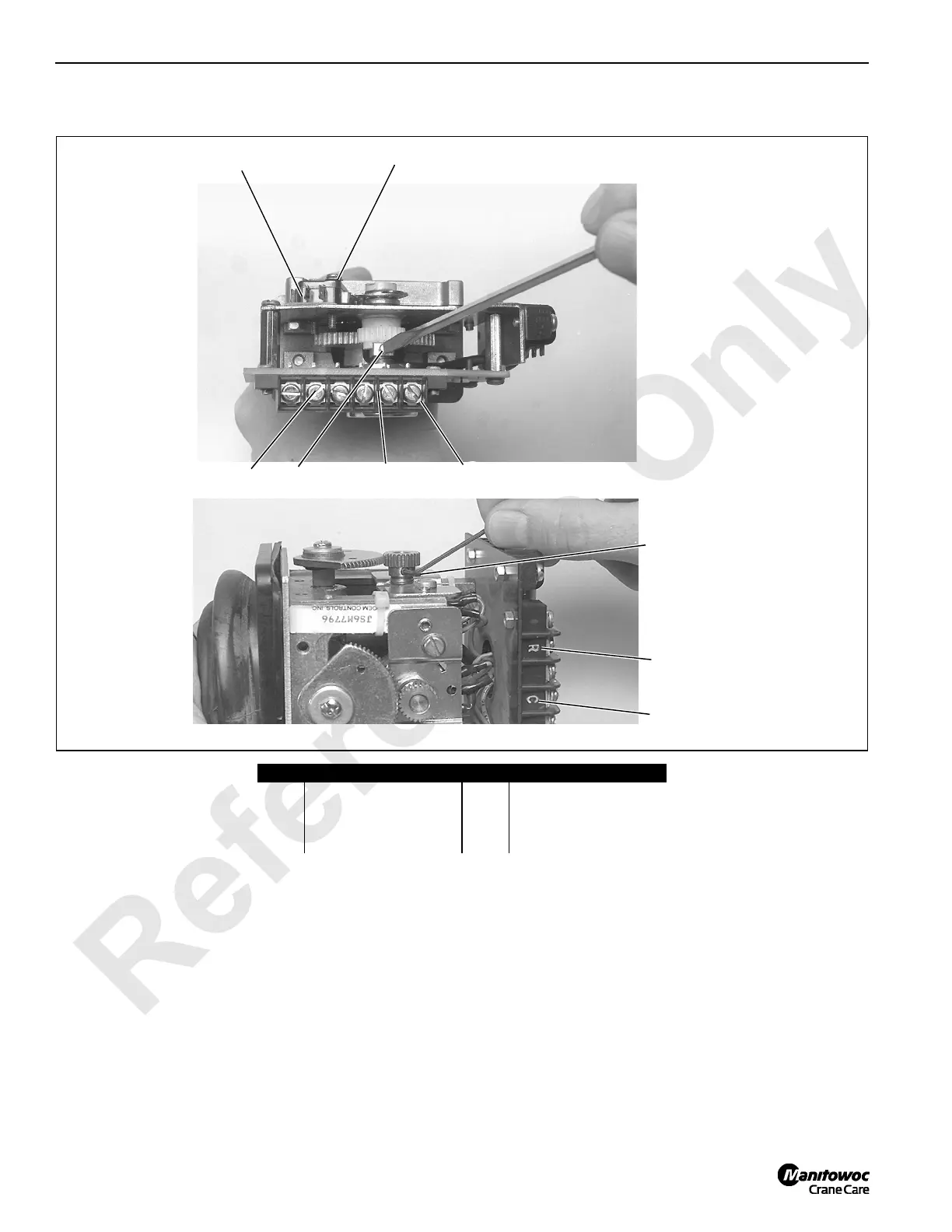

The double axis boom/swing handle is adjusted in the same

manner but involves loosening and tightening two socket set

screws on the gear collar instead of the slotted set screw on

the single axis controller.

Item Description Item Description

1 Neutral (snap) switch 5 Terminal C center

2 Jumper connection (N/O) 6 Potentiometer

3 Ground terminal R 7 Socket set screw (1 of 2)

4 Slotted set screw

2

1

3

7

Single Axis

Controller

Double Axis

Controller

AA318

FIGURE 10-10

5

4

5

AA318

6

3

Loading...

Loading...