Manitowoc Published 10-01-2012, Control # 045-08 1-15

777 SERVICE MANUAL INTRODUCTION

1

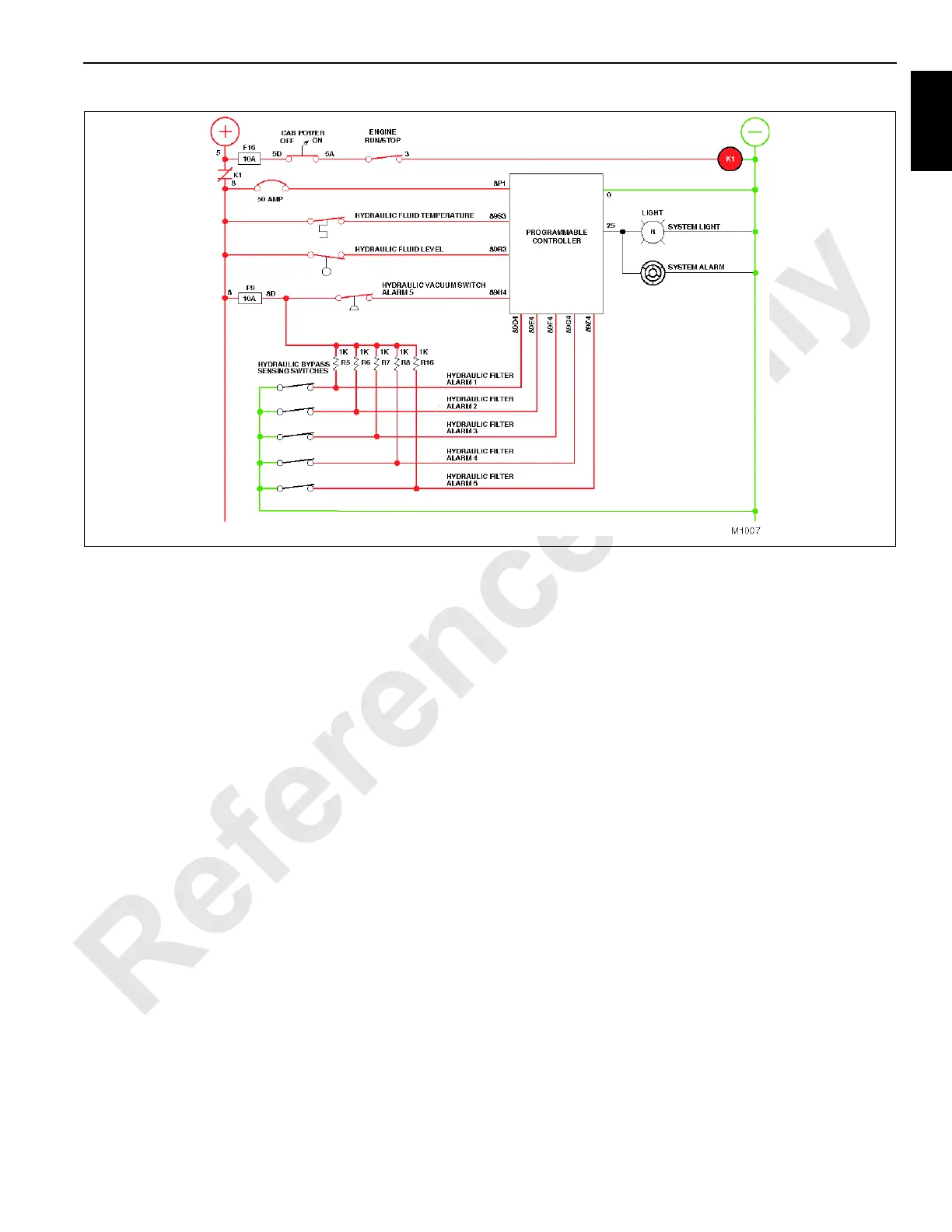

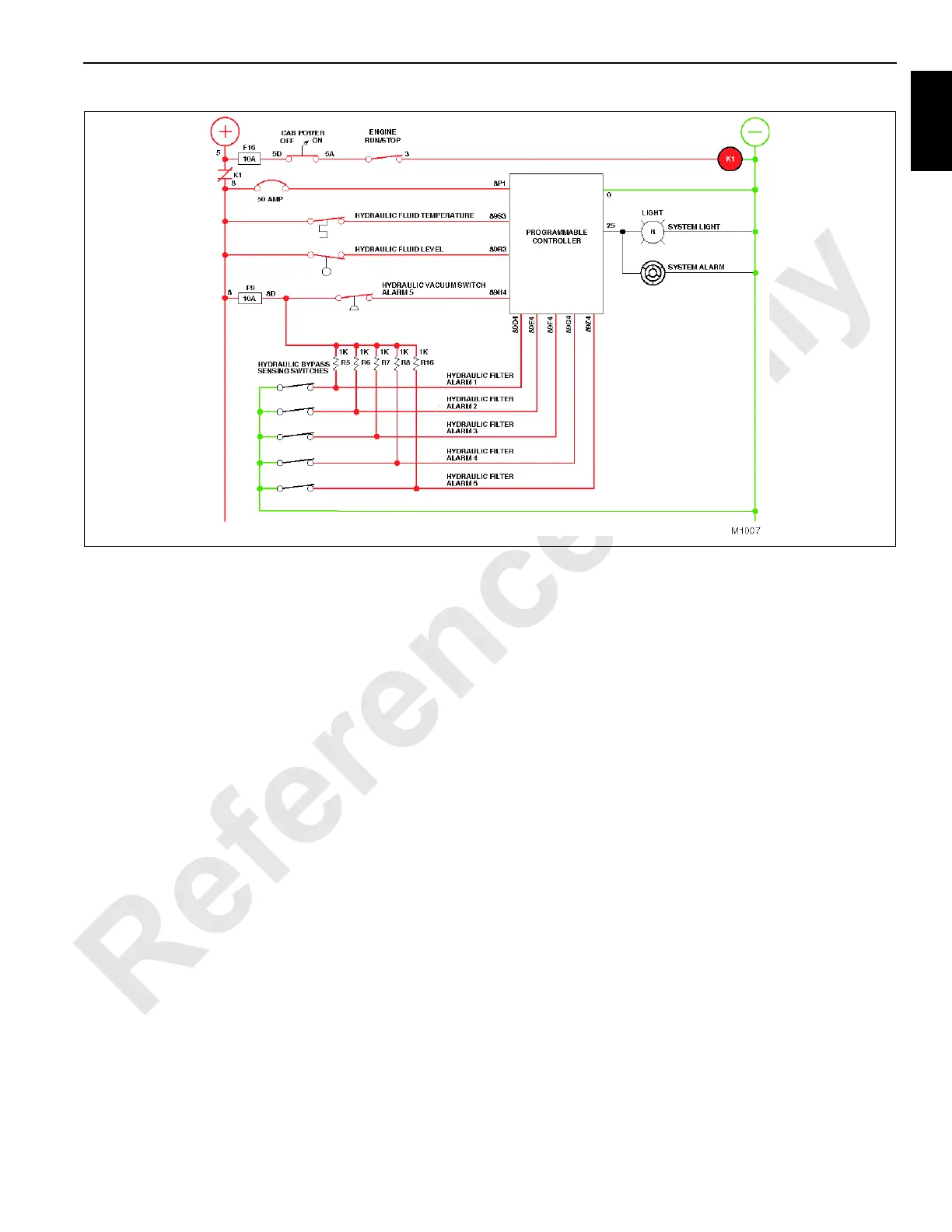

The front, rear, and auxiliary (optional) hoist pumps have

charge pressure filtration to meet the needs of each hoist’s

closed-loop circuit. In this method of filtration, charge pump

section of each pump (14) withdraws oil from the tank and

pumps it through a remote filter adapter into each filter (15)

to be processed. The oil is then routed back into the front,

rear, or auxiliary hoist pump through the remote filter

adapter. Note that the filter element contained in each filter

(15) has a rating of 13. As the element becomes soiled, the

pressure differential between the inlet and discharge flow

ports of the filter increases. When the filter 2, 3, or 6

hydraulic sensing switch on the filter head detects the

pressure differential to be 40 psi (2.8 bar), the switch closes

to complete the circuit to the PC. The PC responds by

sending a diagnostic message HYDRAULIC FILTER 2 for

front hoist, HYDRAULIC FILTER 3 for rear hoist, hydraulic

filter 6 for auxiliary drum) to the operator display, indicating

filter 2, 3, or 6 requires servicing, and activating fault system

light and fault system alarm. The affected filter must be

replaced at this time.

A supercharge filtration circuit supplies filtered oil to the

charge pumps of the boom, swing, and travel systems. This

circuit uses accessory pump (1) to withdraw oil from the tank

and deliver it at a pressure up to 75 psi (5 bar) through filter 1

and into supercharge manifold (16). The pressure differential

between the inlet and discharge flow ports of the filter

increases as the element becomes soiled, causing the filter 1

hydraulic sensing switch on the filter head to close and

complete the circuit to the PC. The PC responds by sending

a diagnostic message HYDRAULIC FILTER 1 to the operator

display, indicating filter 1 requires servicing, and activating

fault system light and fault system alarm. The filter must be

replaced at this time.

System filtration does not transform oil that has deteriorated

from prolonged use into a purified fluid. Factors affecting the

service life of hydraulic fluid include high operating

temperatures, excessive exposure to moisture or dust in the

work area, high concentrations of contaminant particles in

the oil, or admixtures to the oil of unlike viscosity or chemical

composition. A program to test or replace the hydraulic oil at

timely intervals should be established in order to ensure

efficient operation of the crane’s hydraulic system.

See the Lubrication Guide in Section 9 if this manual for

recommended replacement oil for the hydraulic system.

Suction Manifold

Supply oil to load drum and auxiliary hoist pumps (14) and

accessory pump (1) is obtained from suction manifold (17).

Suction manifold has a 3-inch service shut-off valve (18).

During hydraulic system maintenance operation, the valve

can be closed.

FIGURE 1-9

Loading...

Loading...