BOOM 777 SERVICE MANUAL

4-18 Published 10-01-2012, Control # 045-08

6. Proper safety equipment for working at heights above

the ground.

7. Proper safety apparel.

8. Safe and proper hand tools (wire brush, clamps, grinder,

etc.).

9. Oxy-fuel cutting and preheating torch.

10. Heat resistant blankets for covering the weld repairs and

protecting the lattice section from sparks and spalls.

Repair Procedures and Processes

Manitowoc Crane Care will supply the following

documentation when required:

1. Welding instructions.

2. Modification drawings.

3. Non-destructive testing and inspection requirements.

4. Straightening requirements and processes.

5. Machining requirements.

6. Paint requirements and recommendations.

Lacing Replacement

1. The lacing/lacings will need to be identified prior to

removal. Do not remove more than one lacing at a time

on a panel to ensure straightness of the chords. Use a

fillet weld gauge to measure the toe/heel of the weld and

record the dimension for reference.

NOTE Always replace diagonal lacings first. Diagonal

lacings run from one corner to another (for

example, from upper left chord to lower right

chord).

Always replace the center lacing first in a series of

damaged lacings. This will assist in maintaining the

cross sectional dimensions of the section. Then

replace the remaining lacings, first on one side and

then on the other side of center.

Special instructions are provided starting on

page page 4-19 for removing:

• End lacing.

• Lacings on a tapered lattice section.

• Lacings on a lattice section with a bent or bowed

chord member.

2. Use a paint marker to reference the location of the

damaged lacing on the chord member (Figure 4-18).

Transfer the marks out of the repair area so they are not

removed during the lacing replacement process. These

marks will help locate the replacement lacing.

3. Use the following settings for the carbon arc electrode

size being used:

Table 1 Carbon Arc Parameters

4. Leave a minimum of 1/8” (3,2 mm) of material and grind

the remaining material to match the existing chord

profile. Take care not to damage the chord or reduce the

wall thickness.

5. A cutting torch may be used to remove the lacing. Leave

at least 1/4 in (6 mm) of material and grind the remaining

material to match the existing chord profile. Take care

not to overheat or gouge the chord when using a torch

for removal.

6. Gouge marks on the chord are unacceptable. Stop all

work if chord is damaged and contact Manitowoc

Crane Care via your Manitowoc Distributor.

7. M.T. or P.T. inspect the chord for soundness prior to

fitting the new lacing.

NOTE Manitowoc recommends the N.D.T personnel be

certified to A.S.N.T. Level ll.

8. Remove all grease, paint and oil from the weld zone on

the replacement lacing.

9. Fit and tack the new lacing using the reference marks

and existing lacings on both sides for location.

The gap between the chord and lacing must not exceed

1/16 in (1,6 mm) at either end.

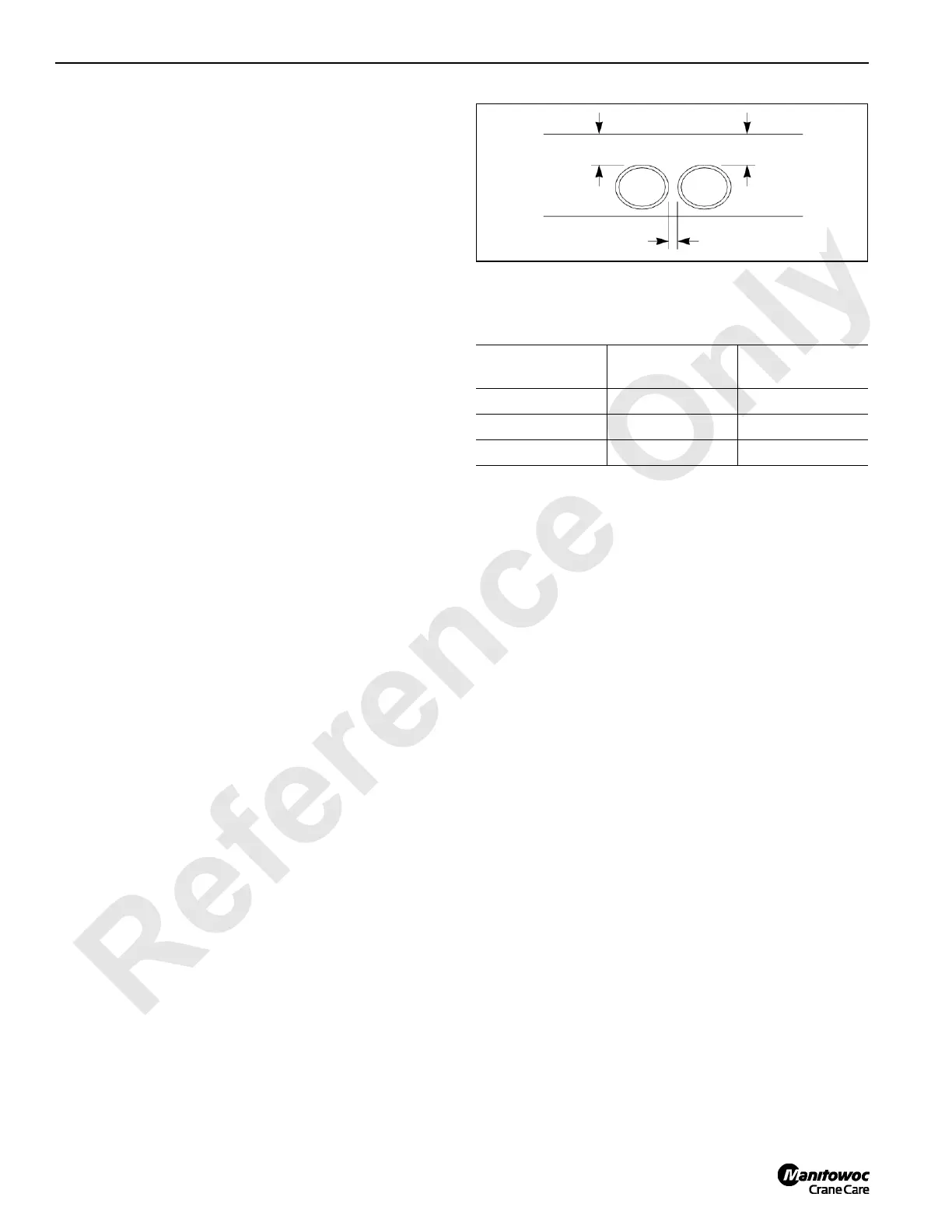

10. Use S.M.A.W. for tacking (Figure 4-19). All tack welds

must be crack free and small enough to weld over. Use

3/32 in (2,4 mm) diameter stick electrode for tacking the

lacing.

• A total of two tack welds are to be made only in the

locations shown in Figure 4-19. Do not tack weld

toe or heel of lacing.

• The tacks should be 1-1/2 in (38,1 mm) long and

located on the sides of the lacing.

Electrode Size

Minimum

Amperage

Maximum

Amperage

5/32 in (4,0 mm) 90 amps 150 amps

3/16 in (4,8 mm) 200 amps 250 amps

1/4 in (6,4 mm) 300 amps 400 amps

FIGURE 4-18

Loading...

Loading...