INTRODUCTION 777 SERVICE MANUAL

1-66 Published 10-01-2012, Control # 045-08

stroke the pump in the up direction. Oil then flows from pump

port A to port A of auxiliary hoist motor.

Auxiliary hoist pressure sender supplies the PC with

pressure information, which the PC compares to the

memorized holding pressure of the auxiliary hoist. When

adequate pressure is available, the PC energizes HS9 to

shift the brake valve. This initiates full release of park brake

and auxiliary hoist motor raises the load.

The PC governs the raising speed of the load by varying the

voltage to the pump (up) EDC in proportion to movement of

the control handle. The angle of the pump swashplate is

increased as the control handle is moved farther backward,

pumping more oil to the motor and raising the load faster.

As control handle approaches the full handle command

position, and if lifting conditions permit, the PC instructs the

auxiliary hoist motor PCP valve to shift in proportion to

handle position and redirect oil flow to motor servo cylinder.

This allows the servo mechanism to shift the motor gradually

toward to minimum displacement for maximum motor speed

at less operating torque.

As control handle returns to the off position, the PC

commands the auxiliary hoist pump (up) EDC to decrease

the angle of the pump swashplate, causing a reduction in oil

flow output. The PC also instructs the auxiliary hoist motor

PCP valve to shift in proportion to handle position, the

auxiliary hoist motor to maximum displacement for slower

output speed to slow the drum rotation. When the control

handle is fully off, the PC memorizes the pressure required to

support the load and de-energizes HS9 to apply the brake

after the control handle neutral switch opens or after

receiving a zero command from drum speed sender.

Auxiliary Hoist Lower

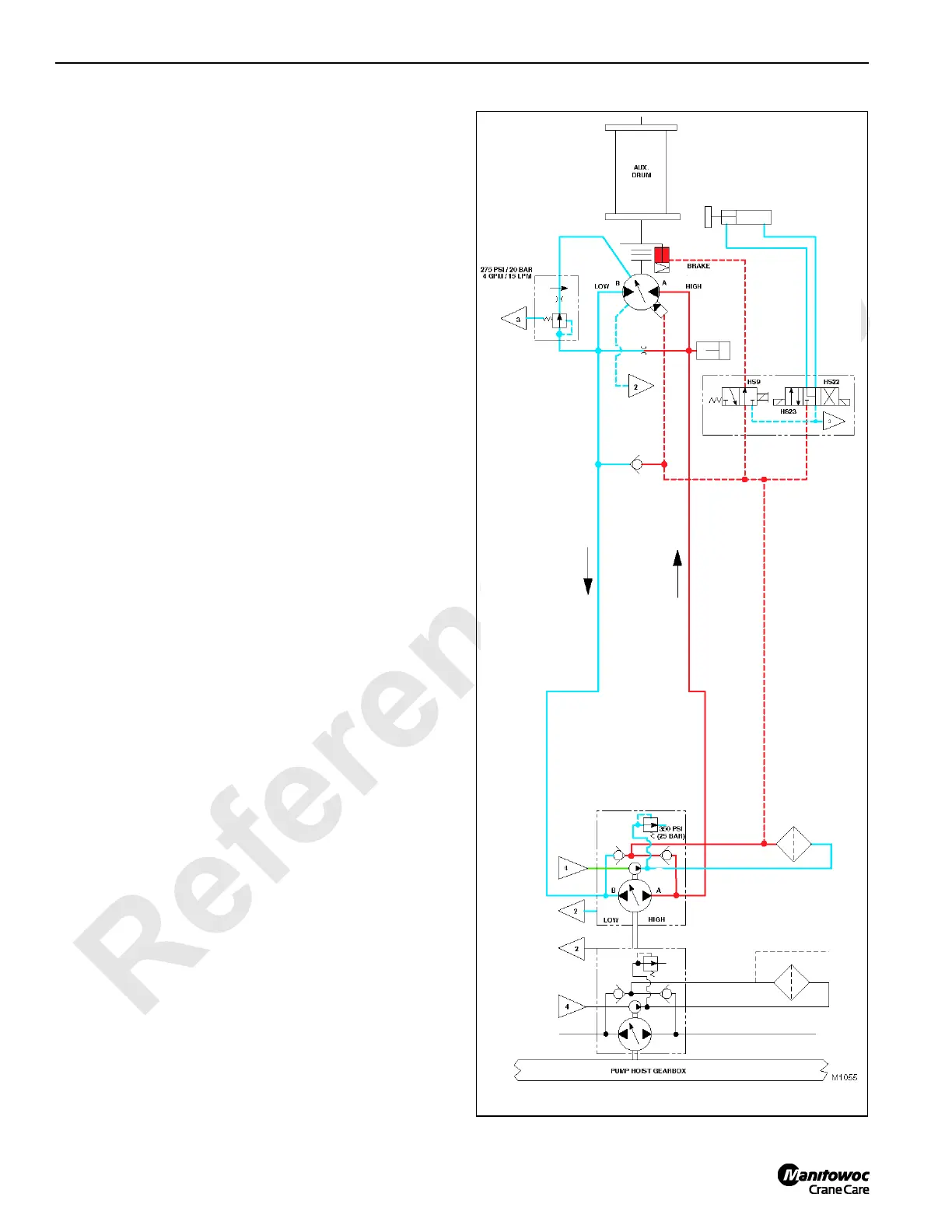

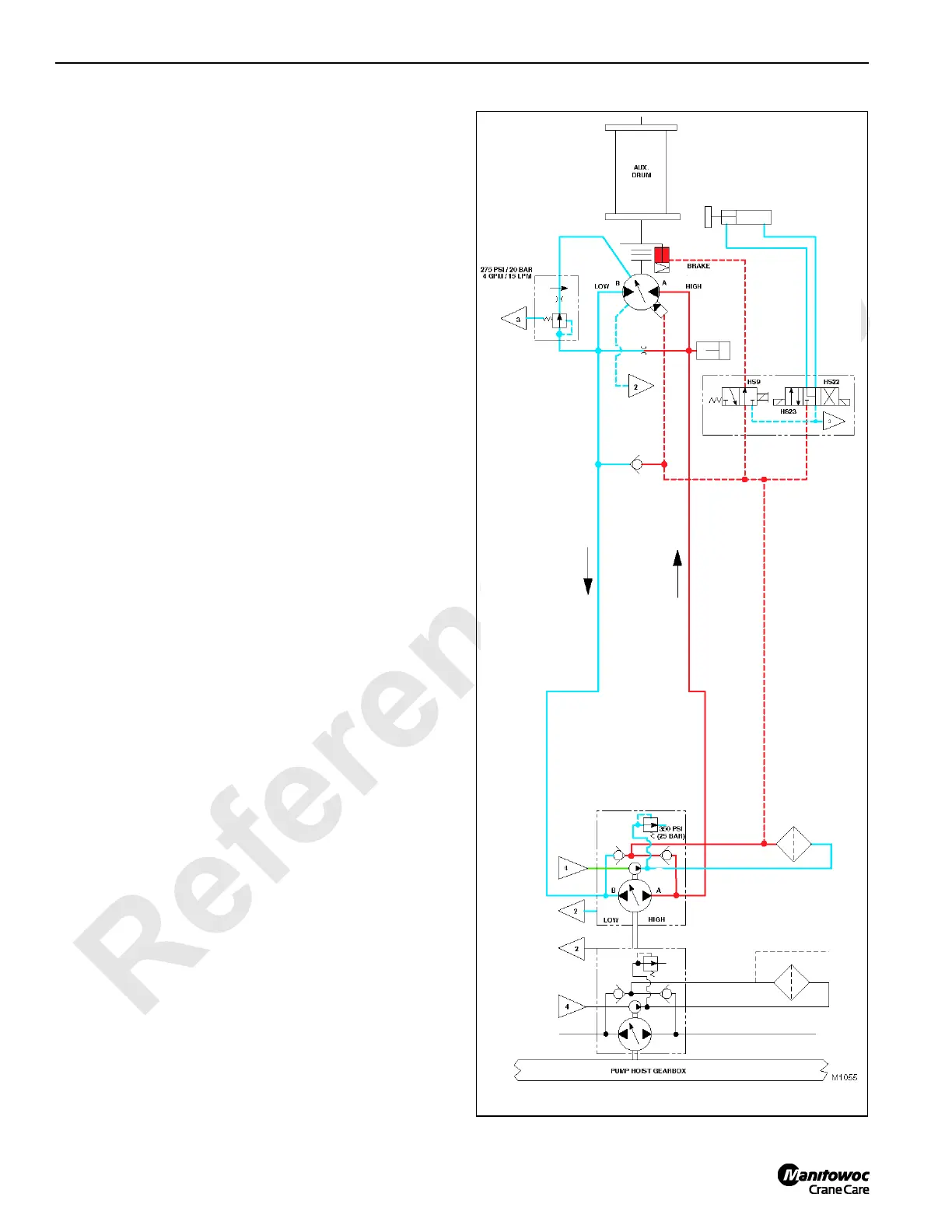

See Figures 1-48 and 1-49 for following procedures.

When control handle is pushed forward for down operation,

the handle neutral switch closes, completing a regulated

voltage circuit from the handle potentiometer to the PC. The

PC interprets the signal for speed and direction and closes

regulated voltage circuits to the auxiliary hoist pump (down)

EDC, auxiliary hoist motor PCP, and auxiliary drum park

brake hydraulic solenoid HS9. These circuits will close only if

the seat switch is closed, if the auxiliary drum park switch is

off, the auxiliary drum pawl switch is disengaged, applicable

operating limit switches are closed, and no system or

operating faults are present.

Before the auxiliary drum brake is released, the PC supplies

regulated voltage to the auxiliary pump (up) EDC. The PC

programming requires auxiliary hoist pump to stroke

momentarily in the hoisting direction to ensure adequate

pressure is present to hold the load after full release of the

brake.

FIGURE 1-48

Loading...

Loading...