Manitowoc Published 10-01-2012, Control # 045-08 1-67

777 SERVICE MANUAL INTRODUCTION

1

Auxiliary hoist pressure sender supplies the PC with

pressure development data that the PC compares to the

memorized holding pressure of the auxiliary hoist. When

adequate pressure is available, the PC energizes HS9 to

shift brake valve, releasing the drum brake while de-

energizing the (up) EDC and energizing the (down) EDC.

The regulated voltage to the auxiliary hoist pump (down)

EDC then causes the swashplate to tilt, stroking the pump in

the down direction and directing oil flow from pump port B to

port B of auxiliary hoist motor.

The weight of the load on the auxiliary drum will attempt to

drive the motor faster than return oil is available to the pump.

The auxiliary hoist charge pump maintains the oil supply in

the closed loop circuit at a positive pressure to auxiliary hoist

motor.

The position of the pump swashplate restricts the returning

oil flow and pressure builds on the return side of the closed-

loop circuit, acting as a brake against the auxiliary hoist

motor to control the lowering speed.

The PC governs the lowering speed of the load by varying

the voltage to the pump (down) EDC in proportion to

movement of the control handle. The angle of the pump

swashplate increases as the control handle is moved farther

forward; more oil is allowed to return to the pump, more oil is

pumped to the motor, and the auxiliary drum lowers the load

faster.

As control handle approaches the full handle command

position, and if lifting conditions permit, the PC instructs the

auxiliary hoist motor PCP valve to shift and redirect oil flow to

motor servo cylinder. This allows the servo mechanism to

shift the motor to minimum displacement for maximum motor

speed and less operating torque.

As control handle returns to the off position, the PC

commands the auxiliary hoist pump (down) EDC to decrease

the angle of the pump swashplate, causing a reduction in oil

flow output. The PC also instructs the auxiliary hoist motor

PCP valve to shift auxiliary hoist motor to maximum

displacement in proportion to return handle position for

slower output speed to slow the drum rotation. When the

control handle returns to the neutral handle position, the PC

monitors the system pressure sender while de-energizing

the (down) EDC and momentarily energizing the (up) EDC to

develop the required pressure to support the load. The

monitored load supporting pressure is retained in the

pressure memory bank of the PC. The (up) EDC then de-

energizes while HS9 de-energizes to set the brake after the

control handle neutral switch opens or after receiving a zero

command from drum speed sender.

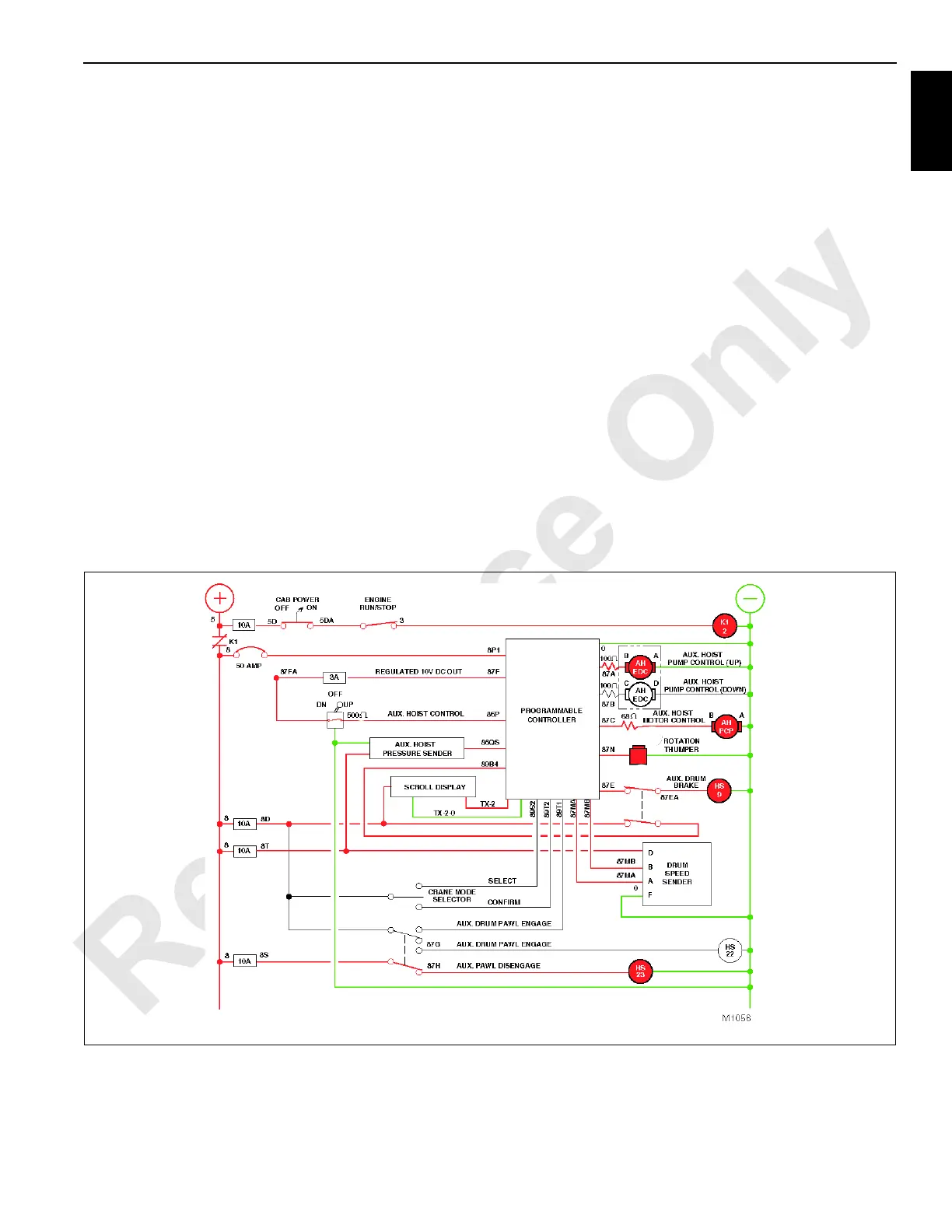

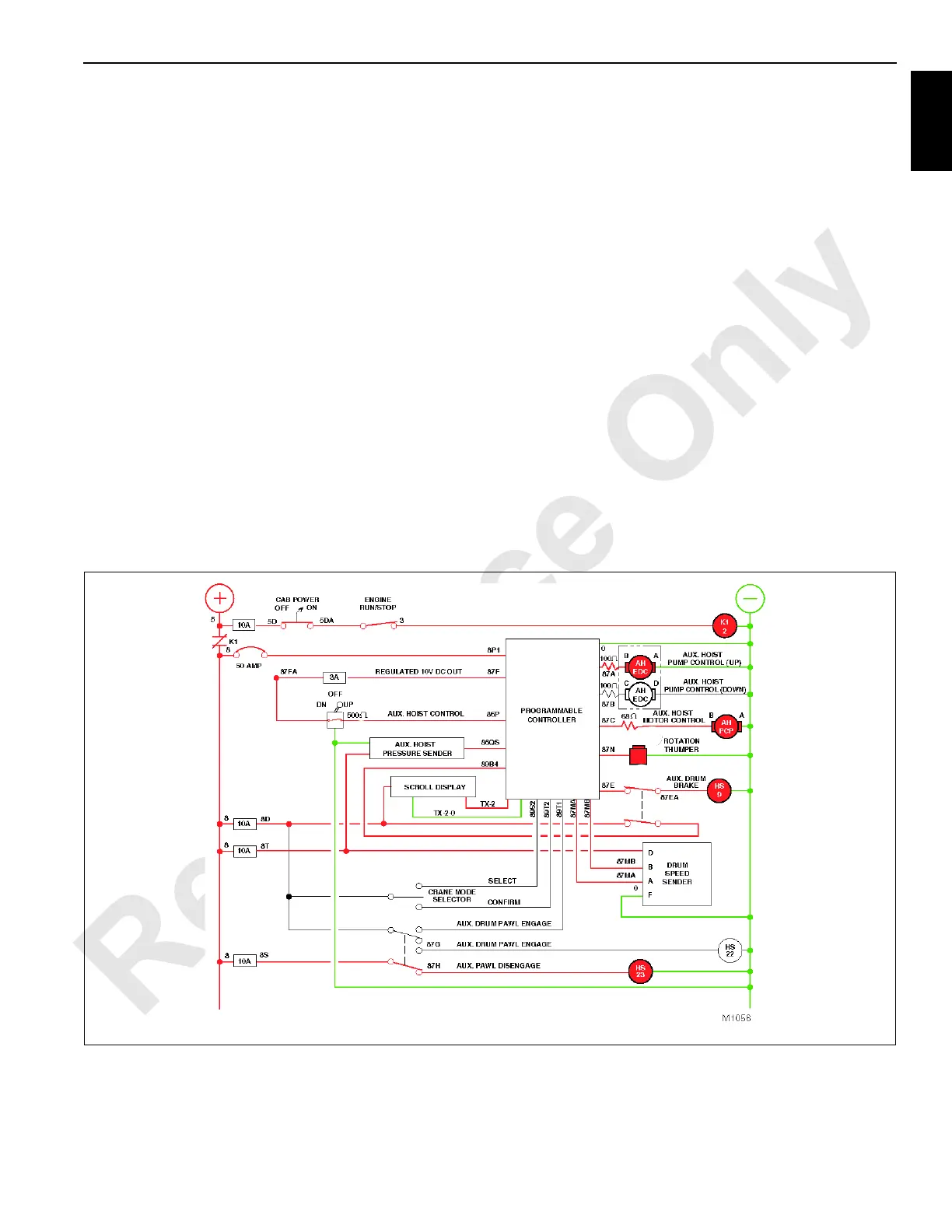

FIGURE 1-49

Loading...

Loading...