POWER TRAIN 777 SERVICE MANUAL

7-4 Published 10-01-2012, Control # 045-08

ENGINE AIR CLEANER MAINTENANCE

Servicing the engine air cleaner is an important maintenance

function:

• A clogged air cleaner filter will prevent adequate air flow

to the engine, resulting in poor starting and increased

exhaust emissions.

• An improperly installed or damaged air cleaner can

allow dirty air to be drawn directly into the engine.

Either condition can result in engine damage.

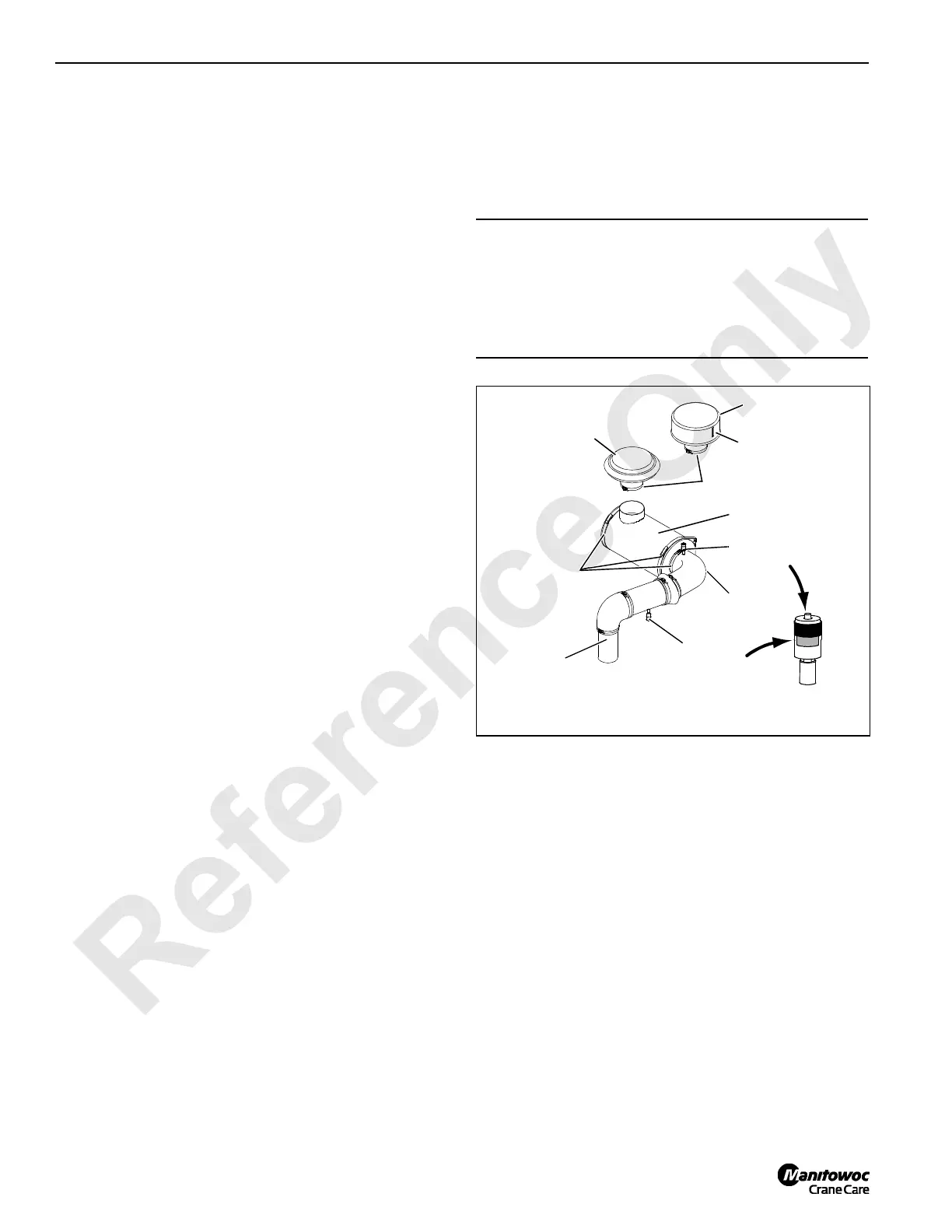

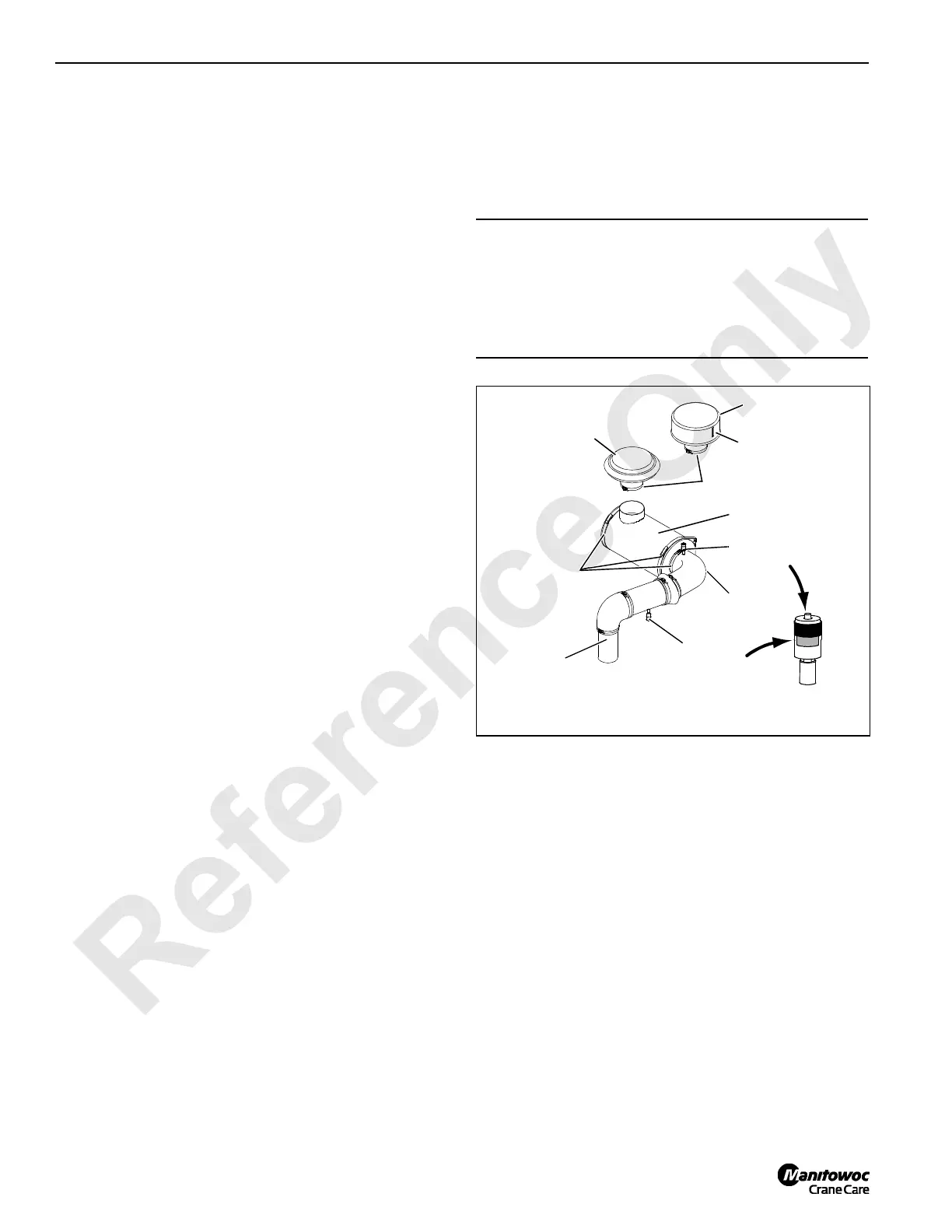

Mounting

The air cleaner is mounted horizontally and fastened to the

engine air intake manifold with rubber elbows and metal

tubes (Figure 7-2).

Inspection

To maintain engine protection and filter service life, inspect

the following areas at regular intervals:

1. Check the service indicator (Figure 7-2) daily with the

engine running.

The indicator gives a visual signal when it is time to

replace the filter.

The red flag in the indicator window rises as the filter fills

with dirt. Replace filter when red flag locks in place at

top of indicator.

When locked in place, the red flag will remain up after

the engine is stopped. When the filter is replaced, push

the button in on the indicator to reset it.

2. Inspect the rubber fittings and the tubes between the air

cleaner and the engine for cracks or other damage

which might allow unfiltered air to enter the engine.

Replace damaged or worn parts.

3. Check the filter body for dents or other damage that may

allow unfiltered air to enter the engine. Replace the filter

if damaged.

4. Check for loose tubing clamps, flange bolts, filter straps,

and clamping brackets. Tighten loose parts.

5. Check that the inlet cap or pre-cleaner is free of

obstructions.

6. If crane has a pre-cleaner, check that discharge hole is

open.

Service

See Figure 7-2 for following procedure.

1. Loosen the clamp securing the air inlet cap or pre-

cleaner and pull it off.

2. Inspect the air inlet cap or pre-cleaner for dirt and

obstructions. Install a new inlet cap or pre-cleaner if it is

damaged.

3. Wash the air inlet cap or pre-cleaner in warm soap and

water and blow it dry with compressed air.

4. Remove the four bolts securing the cover to the engine

enclosure and lift it off.

5. Loosen the clamp securing the rubber elbow to the air

cleaner.

6. While holding the air cleaner, open the clamps securing

it to the engine enclosure.

7. Remove and discard the old air cleaner. Do not reuse

old filter. Do not to allow foreign matter to enter

tubing or air inlet hole to the engine.

8. Slide the new filter into the rubber elbow and close/

tighten the clamps.

9. Reinstall air inlet cap or pre-cleaner and tighten its

clamp.

CAUTION

Engine Damage!

STOP ENGINE before servicing air cleaner, or unfiltered

air will be drawn directly into engine.

Do not attempt to clean and reuse old filter. Discard old

filter and install a new one.

Rubber

Elbow

Clamp

Engine Air

Intake Manifold

Air Cleaner

Service Indicator

(current production)

Clamp

Make sure discharge

hole is open.

Pre-cleaner

Inlet Cap

FIGURE 7-2

A964

Air Cleaner is Mounted Outside Engine Enclosure

Service Indicator

(past production)

Loading...

Loading...