INTRODUCTION 777 SERVICE MANUAL

1-36 Published 10-01-2012, Control # 045-08

SWING SYSTEM

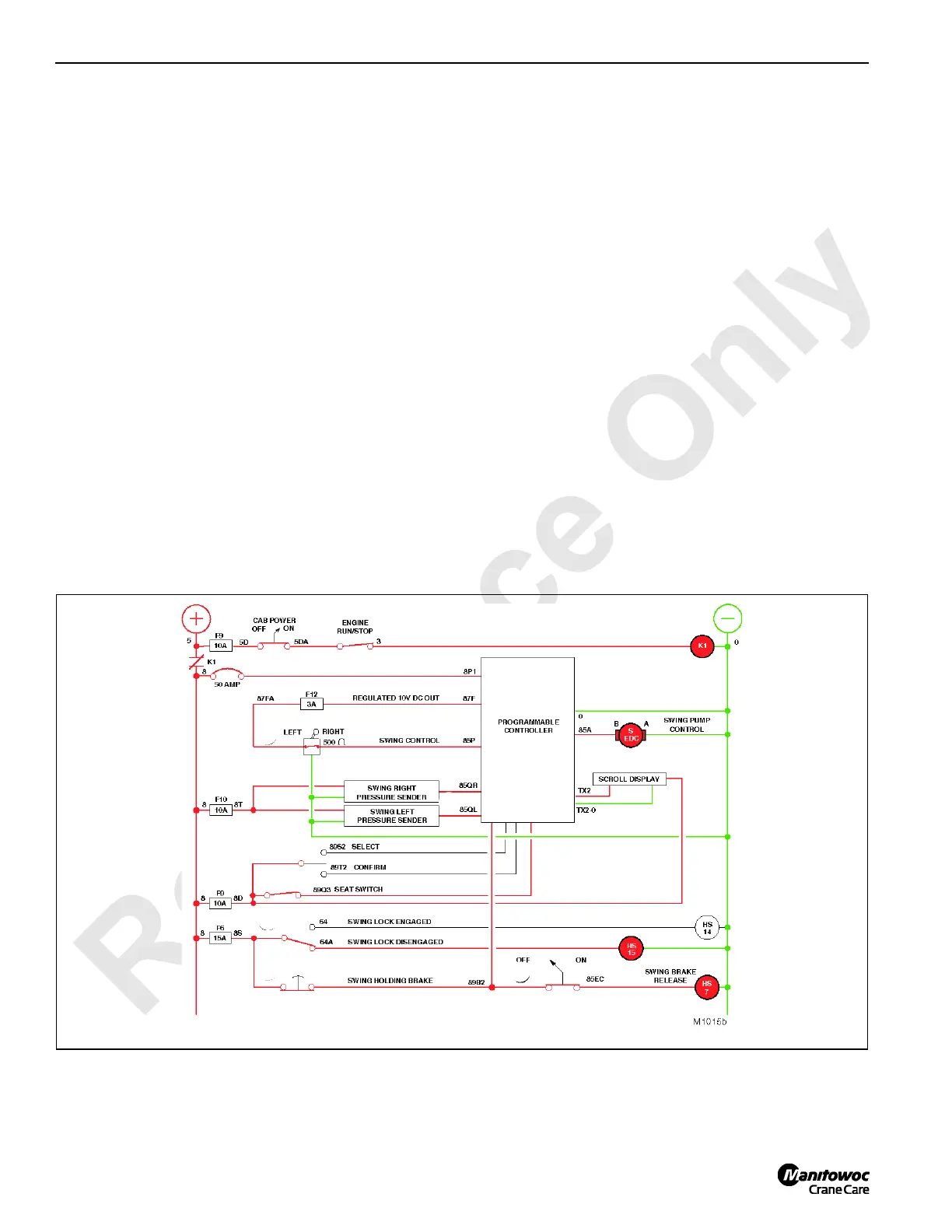

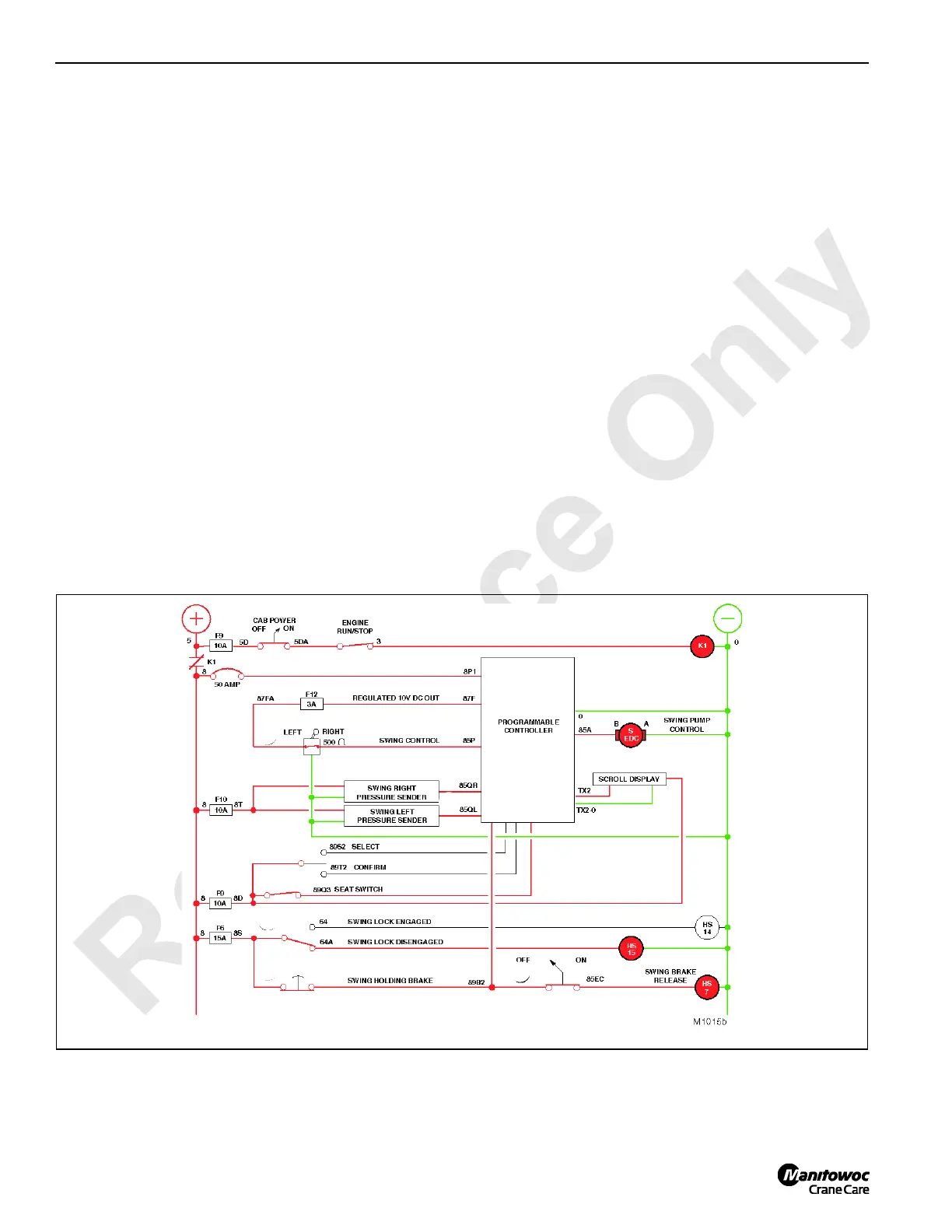

See Figures 1-22 and 1-23 for following procedures.

In order for normal swing operation to occur, the rear load

drum charge pressure must be about 232 psi (16 bar). If the

charge pressure drops below this amount, the hydraulic

brake will begin to partially or fully apply.

After startup, swing park switch, located on the right console

in the operator’s cab, is placed in the off position, closing the

circuit to swing park brake hydraulic solenoid HS7. Swing

brake control valve is shifted against its spring, opening a

path for oil supply from the rear load drum charge pump to

flow through to swing park brake. The pressure compresses

the brake spring to release the brake.

When swing park switch is placed in the on position, the

circuit to swing brake hydraulic solenoid HS7 is opened.

Spring force shifts swing brake valve, closes the path of oil

supply from the rear load drum charge pump and the

pressure in swing park brake is vented to tank so the brake

spring-applies.

Swing holding brake switch, located on the side of swing

control handle, provides the operator with a means of

preventing swing movement. Depressing switch opens a

circuit to the PC. The PC then opens this circuit to the swing

pump EDC, which places swing pump in neutral and applies

the brake by closing the circuit to swing park brake hydraulic

solenoid HS7.

To prevent damage to the swing system components, swing

holding brake switch should only be applied when the

machine is in a stand-still position. When in a swinging

motion, the preferred method of stopping or slowing the

crane is to move swing control handle beyond center in the

opposite direction of movement. This action causes a

hydrodynamic slowing of the rotating bed.

Swing Lock

See Figures 1-22 and 1-24 for following procedures.

The swing lock mechanism is located between the swing

motor and swing brake on the swing motor planetary.

When the swing lock switch, located on the right console in

the operator’s cab, is placed in the disengaged position, the

circuit to swing lock disengage hydraulic solenoid HS15

closes, and the circuit to swing lock engage hydraulic

solenoid HS14 opens. Swing lock valve shifts, opening a

path for oil supply from the rear load drum charge pump to

extend side of the swing lock mechanism piston while oil

from the retract side of the swing lock piston exhaust to tank

through swing lock valve.

FIGURE 1-22

Loading...

Loading...