TROUBLESHOOTING 777 SERVICE MANUAL

10-48 Published 10-01-2012, Control # 045-08

Test 18 – Testing for Pump and Motor Leakage

Testing for pump and motor leakage requires a 3,000 psi

(207 bar) in line flow meter with minimum flow rated capacity

of 10 gpm. Flow meters can be ordered from Manitowoc

Cranes, Inc.

Flow from individual pump and motor drains depend on

several operational factors and settings. Acceptable leakage

is based on the combined case flow of the pump and motor.

The combined case flow from load drum pump and motor

should be equal to a charge pump flow of 8.9 gpm per 1,000

rpm of the engine. The combined case flow from swing or

travel pump and motor should be equal to a charge pump

flow of 4.8 gpm per 1,000 rpm of the engine.

For load drum or travel motor begin by connecting flow meter

between motor case drain hose and port L1 or L2 (use

highest port for testing). To test swing motor, connect the

flow meter between motor case drain hose and case outlet 1.

(See Test 10 for location of motor test ports.) With engine

running at 1,000 rpm, measure motor flow rate. Swing and

travel motors should not exceed 1 gpm case flow at neutral.

At heavier loads and higher rpm, case flow may increase to 4

or 5 gpm. Record results at neutral and reconnect motor

case drain hose to motor port. The difference between circuit

charge pump flow and case flow at neutral is the acceptable

pump case flow at neutral for circuit being tested.

Connect flow meter between pump case drain hose and

pump port L1 or L2 (use highest port for testing). (See Test 9

for location of or pump test ports.) With engine running at

1,000 rpm, measure pump flow rate at neutral and compare

to calculated acceptable pump case flow.

Changes from normal or major changes with increasing

system pressure more than ±1 gpm are indicators or pump

or motor problems.

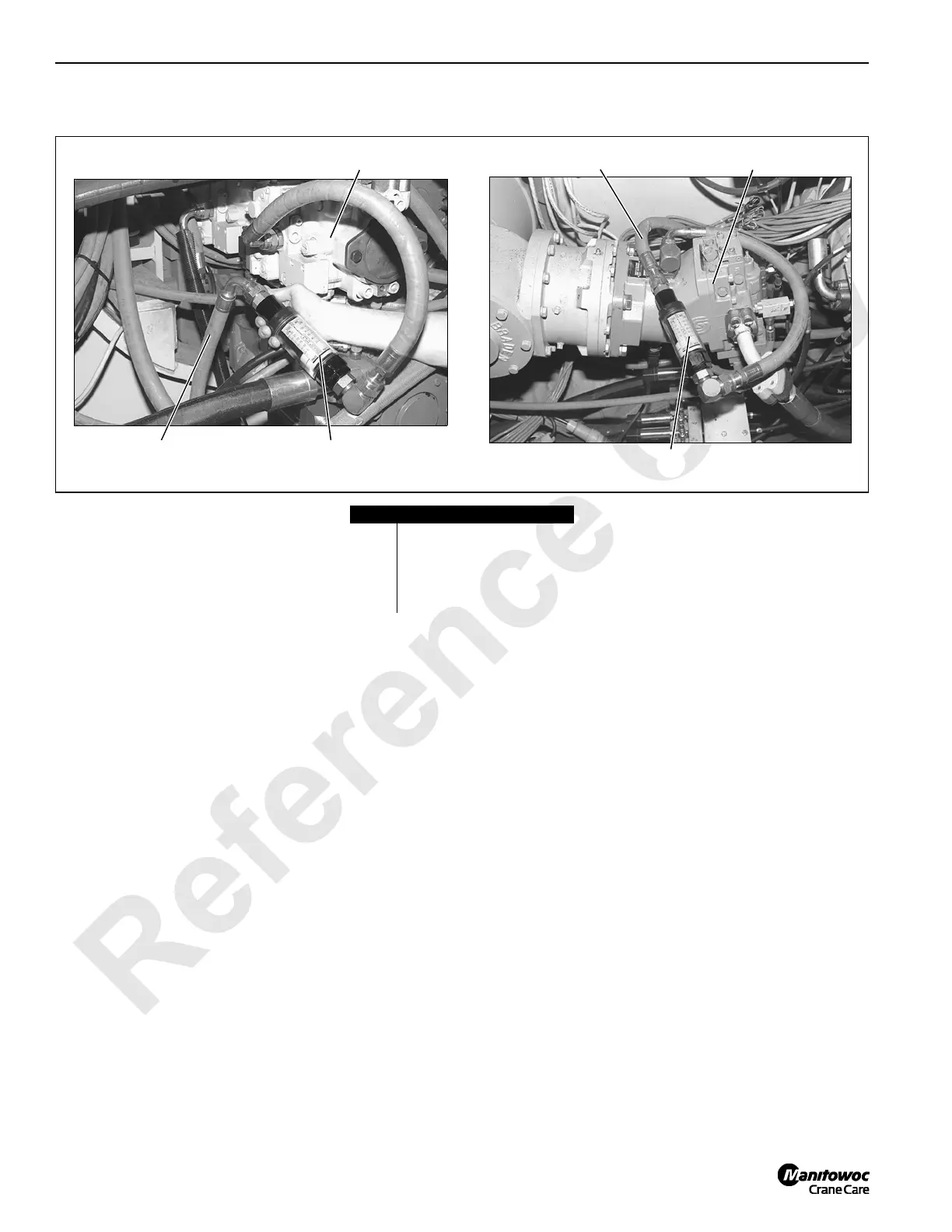

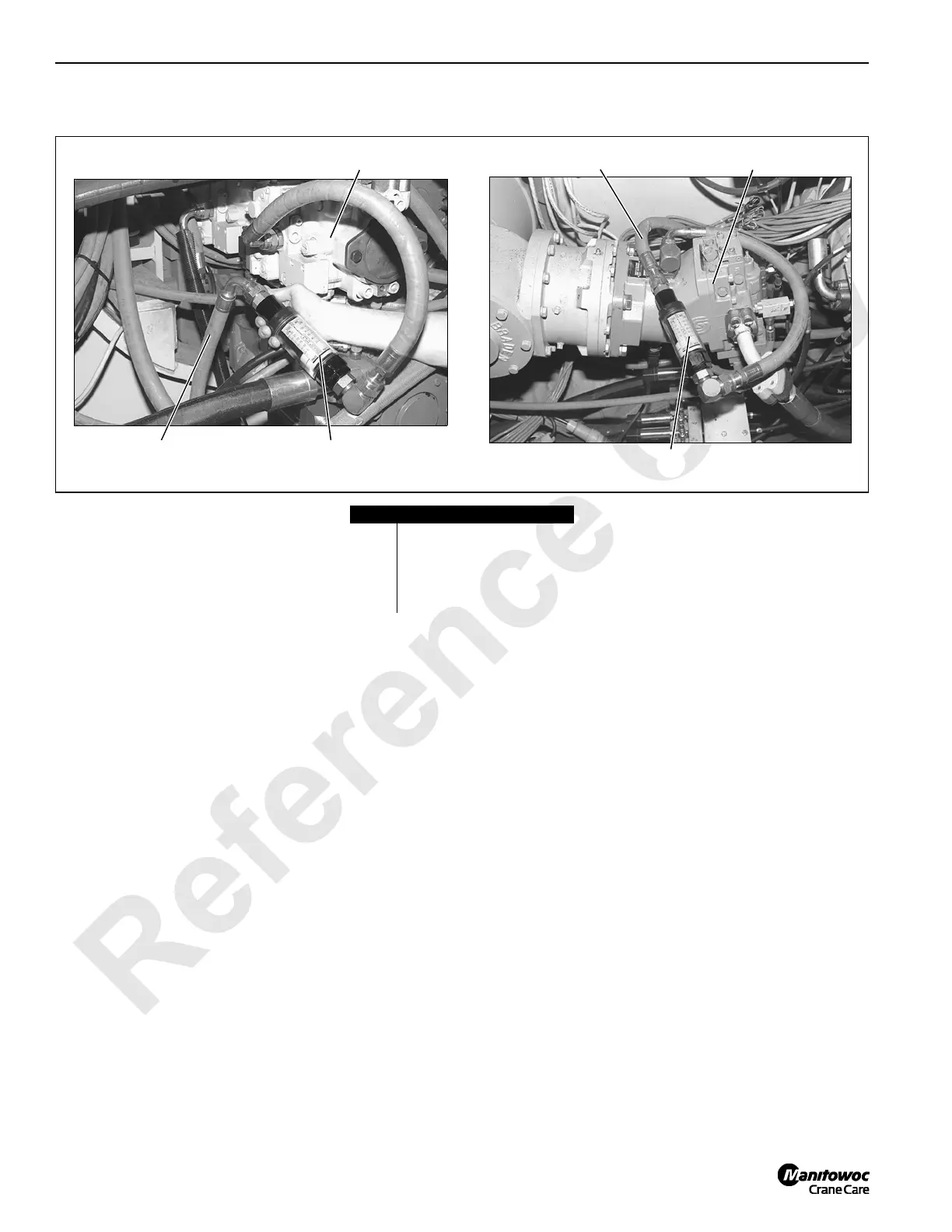

Item Description

1 In line flow meter

2 Pump case drain hose

3Pump

4 Motor case drain hose

5 Motor

FIGURE 10-23

P697

P697

2

1

3

5

4

1

Loading...

Loading...