Manitowoc Published 10-01-2012, Control # 045-08 1-43

777 SERVICE MANUAL INTRODUCTION

1

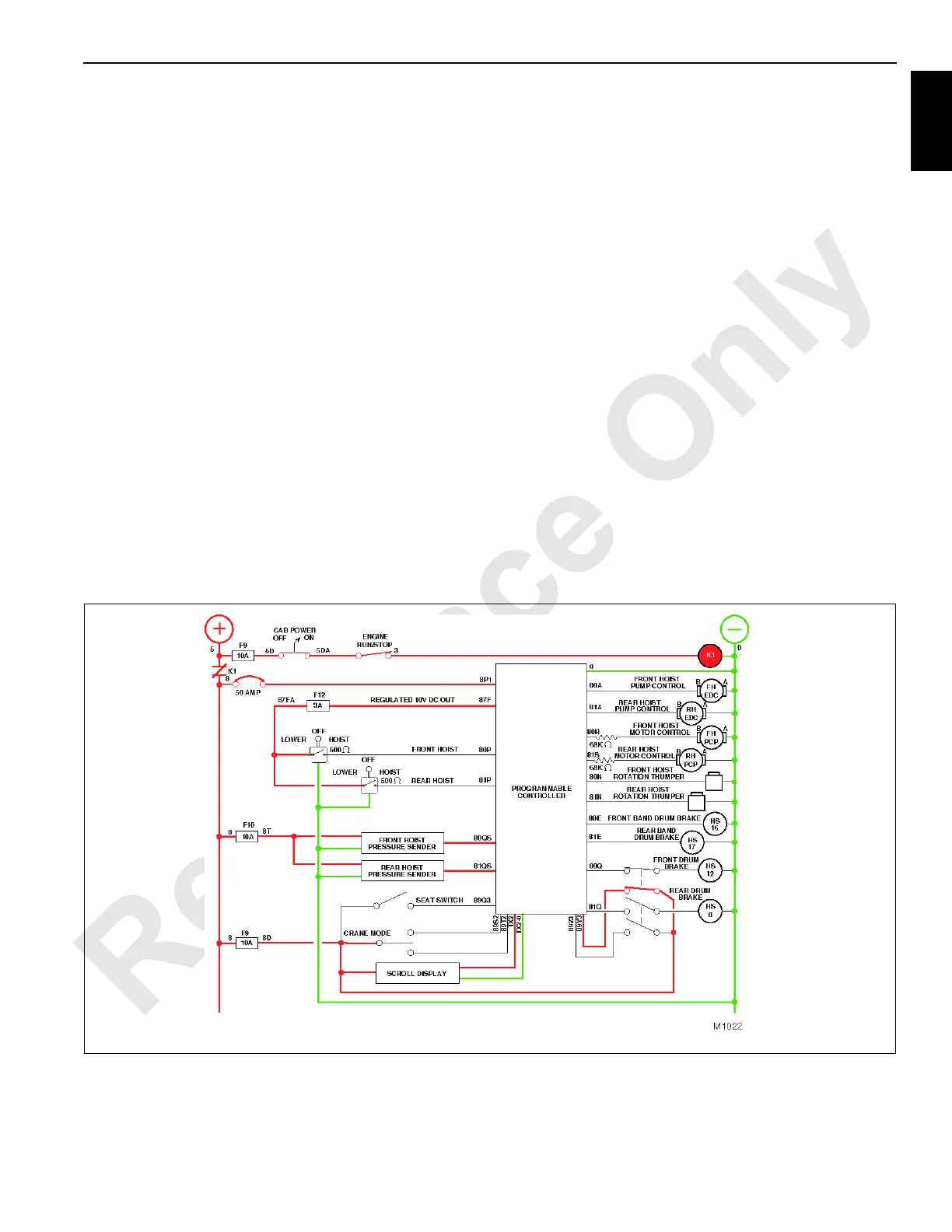

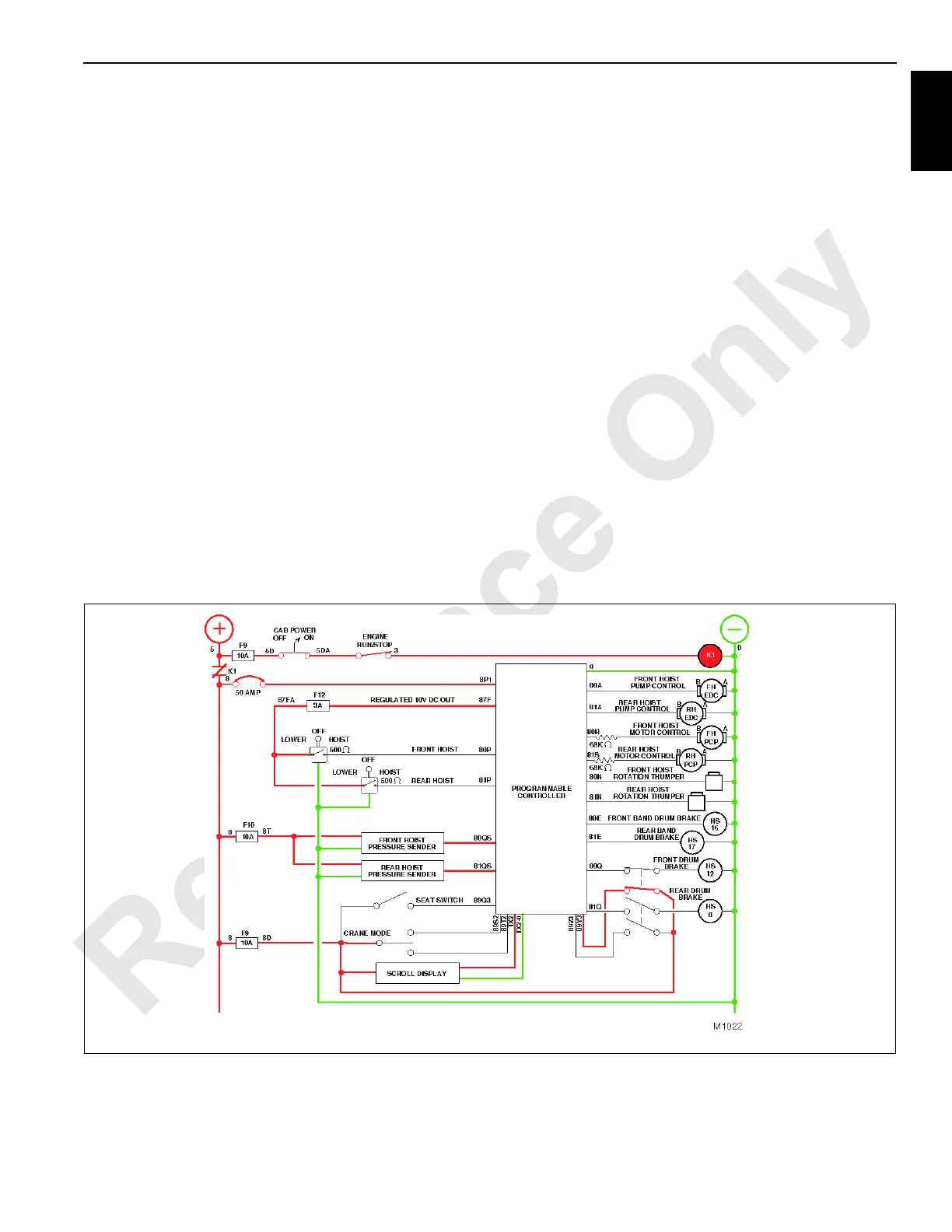

LOAD DRUM (FULL POWER MODE)

See Figures 1-29, 1-30, and 1-31 for following procedures.

The following description is for the front drum without

optional clutch assembly while operating in full power mode.

Function of the rear drum in full power mode is identical. The

clutch assembly is described in the free fall mode section of

this manual.

With free fall, the free fall switch must be closed for brakes to

release and pump to go on stroke.

Front and rear hoist control handles are located adjacent to

one another on right console in the operator’s cab. The

position of these handles may be interchanged depending

on the functional orientation of the front and rear drums.

The hydraulic connection between front hoist pump and front

hoist motor forms a simple closed-loop circuit. Make-up oil

from front hoist charge pump replaces oil in the system that

is primarily displaced due to internal leakage of the pump

and motor assemblies.

If front drum park switch located on the front console in the

operator’s cab, is placed in the ON position, the front hoist

control handle circuit to the PC opens and does not complete

the circuit from the PC to front drum disc brake hydraulic

solenoid HS12 and band brake solenoid HS16. Because

these circuits are open, front drum hydraulic disc and band

brakes remain applied and front hoist pump does not stroke

in response to movement of front hoist control handle.

When performing liftcrane, clamshell, or luffing operations in

full power mode, the brake function employs two

independent brake systems, band brake and hydraulic disc

brake, each hydraulically actuated.

The hydraulic disc brake is spring applied/pressure released

and is controlled automatically by the PC in conjunction with

movement of front drum control handle. Release of brake

during operation of the front drum is sourced from 350 psi

(24 bar) charge pressure pump of the closed-loop circuit.

When releasing brake, charge pressure is directed into

brake valve through HS12. If the charge pressure drops to

below 295 psi (20 bar), hydraulic brake application begins; if

the pressure continues to drop to approximately 220 psi (15

bar) or lower, the brake is fully applied.

The band brake is actuated when heavy duty coil spring is

decompressed and the brake band applies a holding

resistance against the drum flange. The PC automatically

energizes the band brake hydraulic solenoid HS16 opening

a path of flow from auxiliary pump to band brake release

cylinder. The brake cylinder piston extends, causing the

heavy duty coil spring to compress, releasing the holding

resistance applied to the drum flange.

FIGURE 1-29

Loading...

Loading...