Manitowoc Published 10-01-2012, Control # 045-08 5-25

777 SERVICE MANUAL HOISTS

5

Load Block and Hook-And-Weight Ball

Maintenance and Inspection

The operating condition of the load block and the hook-and-

weight ball can change daily with use. They must be

inspected daily (at start of each shift) and observed during

operation for any defects which could affect their safe

operation. Correct all defects before using the load block or

the hook-and-weight ball.

Daily inspection and maintenance will include the following

points (see Figure 5-23 and 5-24):

1. Clean load block or the hook-and-weight ball.

2. Lubricate sheaves (if fittings provided), hook trunnion,

hook swivel, and any other part with a grease fitting at

the intervals specified in Lubrication in Section 9 of this

manual.

3. Tighten loose tie-bolts, cap screws, and set screws.

Check that all cotter keys are installed and opened.

4. Check sheaves for uneven wear in the grooves and on

flanges. Check for loose or wobbly sheaves. These

conditions indicate faulty bearings or bushings.

5. Check the fit of wire rope in the groove of each sheave.

An oversize wire rope can crack the lip of sheave flange

causing rapid wear of wire rope and sheave. The groove

must be larger than wire rope, and the groove must be

free of rough edges and burrs.

6. Check that hook, trunnion, and swivel rotate freely

without excessive play. Faulty operation indicates faulty

bushings or bearings or inadequate lubrication.

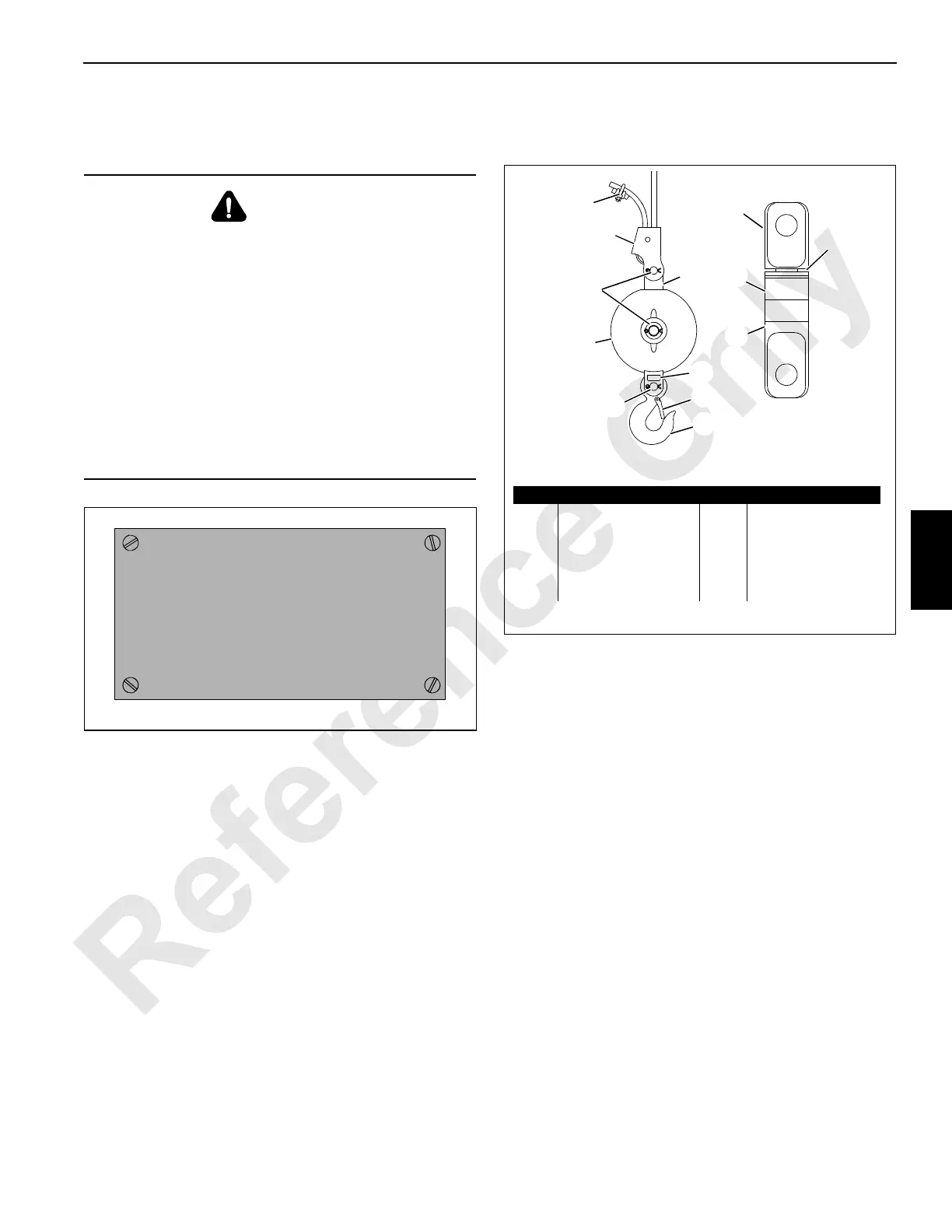

7. Check swivel of hook-and-weight ball for the following

conditions:

• Overloading: Spin swivel by hand; if the motion is

rough or has a ratchet-like effect, swivel bearings

are damaged.

• Side loading: Swivel will turn freely in one spot and

lock-up in another. This condition can also be

checked by looking at the gap (see Figure 5-23)

between barrel and shank (swivel must be removed

from weight ball to check); if the gap is wide on the

side and closed on the other, damage is present.

The gap between barrel and shank is normally 0.020 to

0.050 inches. If the gap increases, swivel-bearing failure

is indicated.

WARNING

Falling Load Hazard!

To prevent load from dropping due to structural failure of

load block or hook-and-weight ball:

• Only use a load block or a hook-and-weight ball

which has a capacity equal to or greater than load to

be handled.

• Do not remove or deface nameplate (Figure 5-22)

attached to load blocks and hook-and-weight balls.

• See “Duplex Hook” topic in Section 4 of Operator’s

Manual for recommended sling angles and capacity

restrictions when load block has duplex or

quadruplex hook.

FIGURE 5-22

CAP.

WT.

MANITOWOC

U.S. TON

LB’s.

NO.

SERIAL NO.

Maximum

Capacity

Weight

of Unit

Manitowoc Part Number

of Unit

Hook-and-Weight Ball

Check

Gap

Here

FIGURE 5-23

A923

Swivel

Item Description Item Description

1 Dead End Clip

6

Hook Latch

2 Socket and Wedge

7

Nameplate

3Tie Bolts

8

Shank

4 Weight Ball

9

Hook Swivel

5Hook

10

Barrel

1

2

3

4

5

6

7

8

9

10

3

9

Loading...

Loading...