BOOM 777 SERVICE MANUAL

4-8 Published 10-01-2012, Control # 045-08

SERVICING BOOM HOIST CYLINDER

1. Lower boom onto blocking at ground level (Figure 4-7).

2. Fully lower mast and pin to boom butt as shown in

Figure 4-7.

3. Move boom hoist control handle to off and park boom

hoist.

4. Stop engine.

5. Exhaust pressure from cylinder valve blocks, as follows:

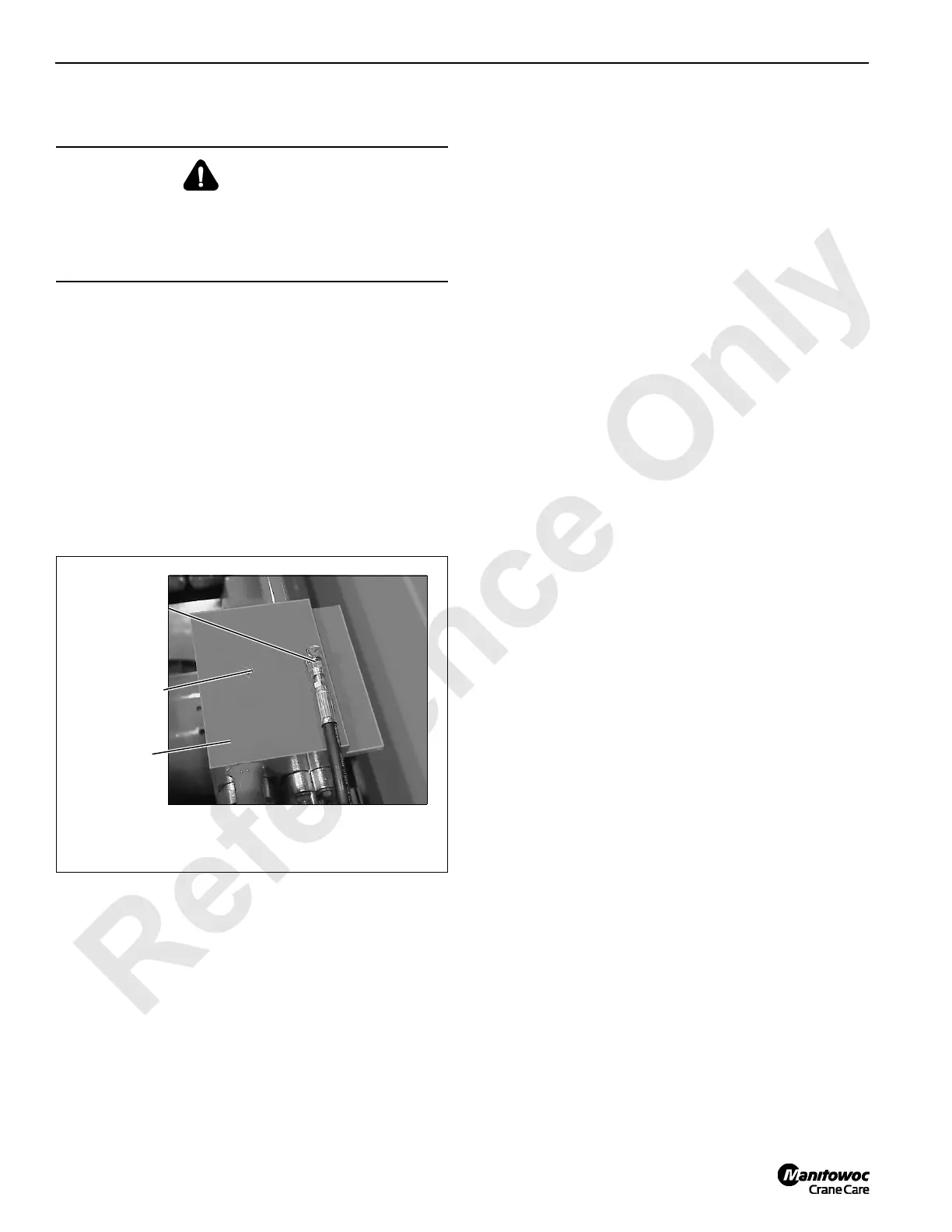

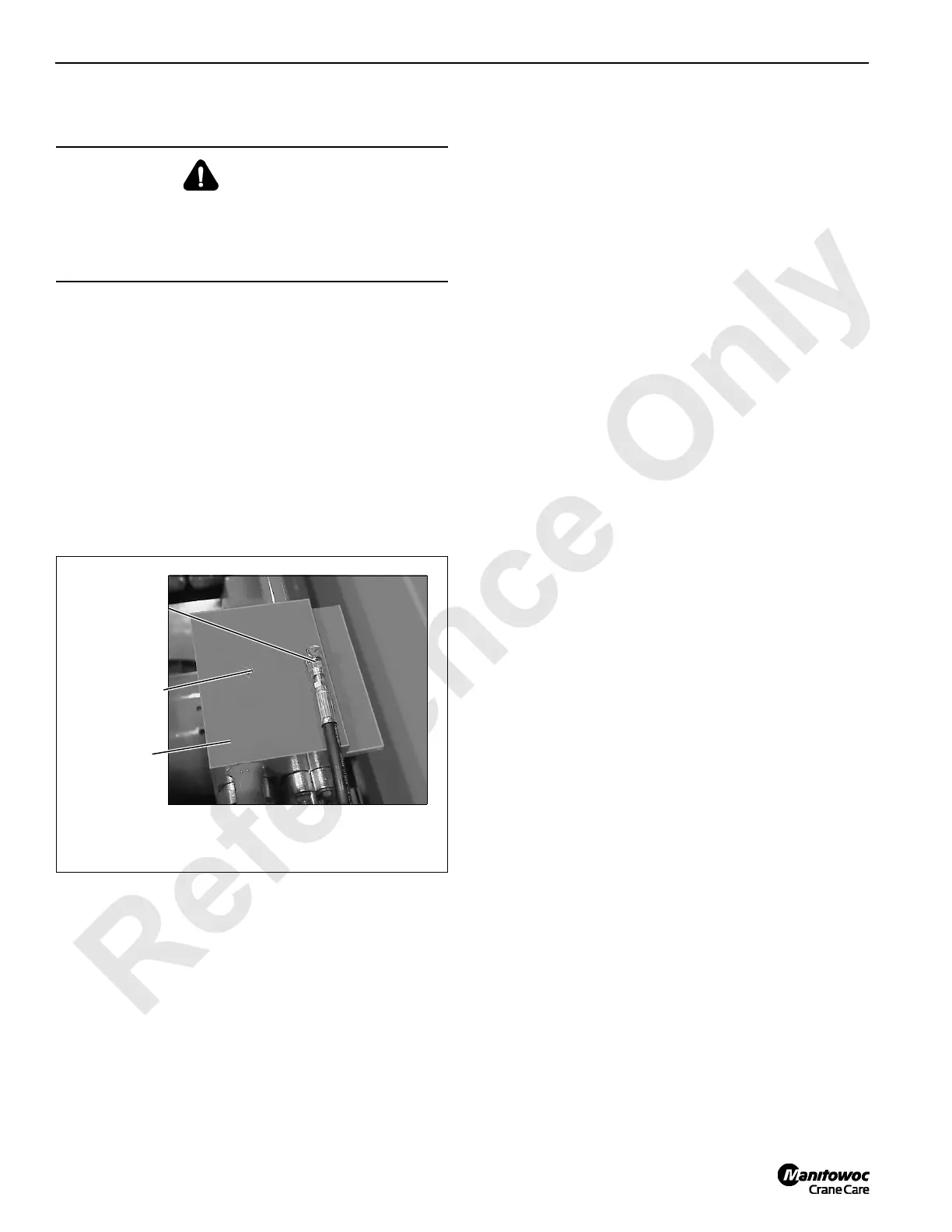

a. Slowly unscrew and remove vent plug from valve

block (Figure 4-8).

b. Slowly unscrew and disconnect pressure sender

line from elbow in valve block (Figure 4-8).

6. It is now safe to remove holding valves, disconnect

remaining hoses, and remove cylinders as required.

7. If boom hoist cylinders were removed, install them at this

time:

a. Pin head end of cylinders to rotating bed. Block

valves on cylinders must face inward.

b. Securely block cylinder bodies on mast (see

Figure 4-7). Do not connect rod end pins to mast.

Both cylinders must be free to extend and retract

when bleeding air.

8. Install holding valves and connect hoses as required:

a. Thoroughly clean all fittings.

b. Make sure all O-rings are properly installed.

c. Apply thread sealant to vent plug threads and

securely install vent plugs.

d. Install and securely tighten holding valves, fittings,

and hoses.

9. Bleed air from boom hoist cylinders as follows:

a. Both cylinder rod ends must be disconnected from

mast. Perform step 7b if not already done.

b. Start and run engine at high idle.

c. Fully extend and retract boom hoist cylinders twice.

Use care not to allow cylinder rod ends to

contact mounting lugs on mast.

d. Check for oil leaks at cylinder valve blocks as

cylinders are operated. Stop engine and correct

leaks if found.

e. Remove blocking and connect cylinder rod ends to

mast.

10. Bleed boom hoist cylinder pressure sender and calibrate

pressure senders (see Pressure Sender Calibration

procedure in Section 2 of this manual).

11. Disconnect mast from boom butt.

12. Slowly raise boom to desired operating position. Then

slowly lower boom approximately 20°. Continue this

procedure until operation is smooth in both directions.

BOOM HOIST CYLINDERS — WELDING

When welding on the subject cranes, weld current can arc

from the boom hoist cylinder barrels to the pistons or rods.

This action can cause damage to the pistons and rods,

causing premature seal failure. Leakage will occur, and the

boom may lower on its own.

Before Welding on Crane

Take the following precautions to prevent damage to the

boom hoist cylinders (and other crane parts such as

bearings, swivels, slewing ring, computers, etc.):

• Disconnect all cables from batteries.

• Disconnect output cables at engine junction box.

• Attach ground cable from welder directly to part being

welded and as close to weld as possible.

• Do not weld on engine or engine mounted parts (per

engine manufacturer).

WARNING

Falling Boom Hazard!

Do not attempt to service boom hoist cylinders (remove

holding valves or disconnect hoses) until following steps

are performed. Boom will lower uncontrolled.

FIGURE 4-8

Valve

Block

P986

Right Side Cylinder Shown (Left Side Cylinder Similar)

Pressure

Sender Line

Vent

Plug

Loading...

Loading...