Manitowoc Published 10-01-2012, Control # 045-08 4-19

777 SERVICE MANUAL BOOM

4

11. Whenever possible, welding shall be done in the

horizontal position.

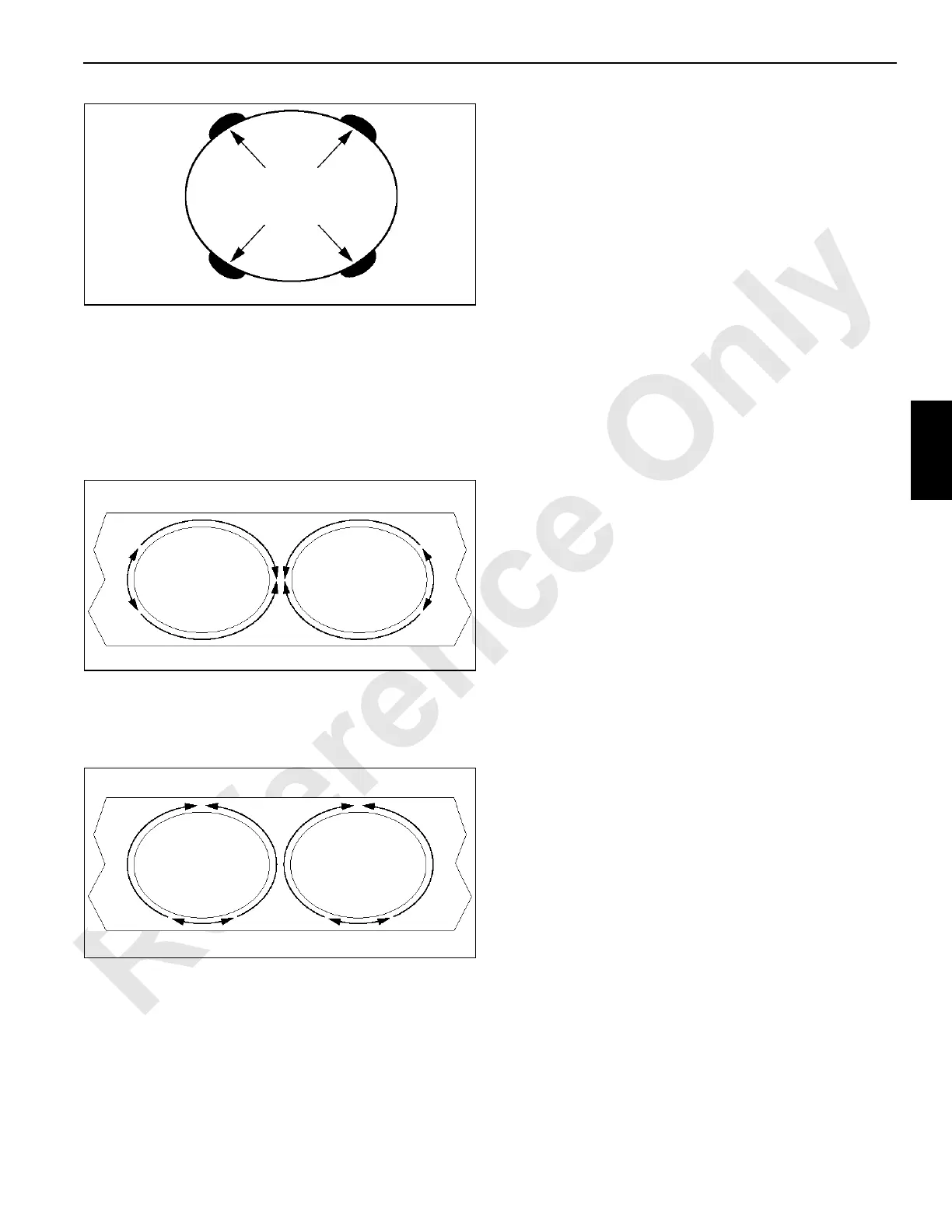

a. Use the following sequence for horizontal and

overhead welding. The weld pass should start at the

heel of the lacing and end on the toe (Figure 4-20).

Pass placement will differ from the horizontal and

the overhead position.

NOTE See Figure 4-24 for pass placement.

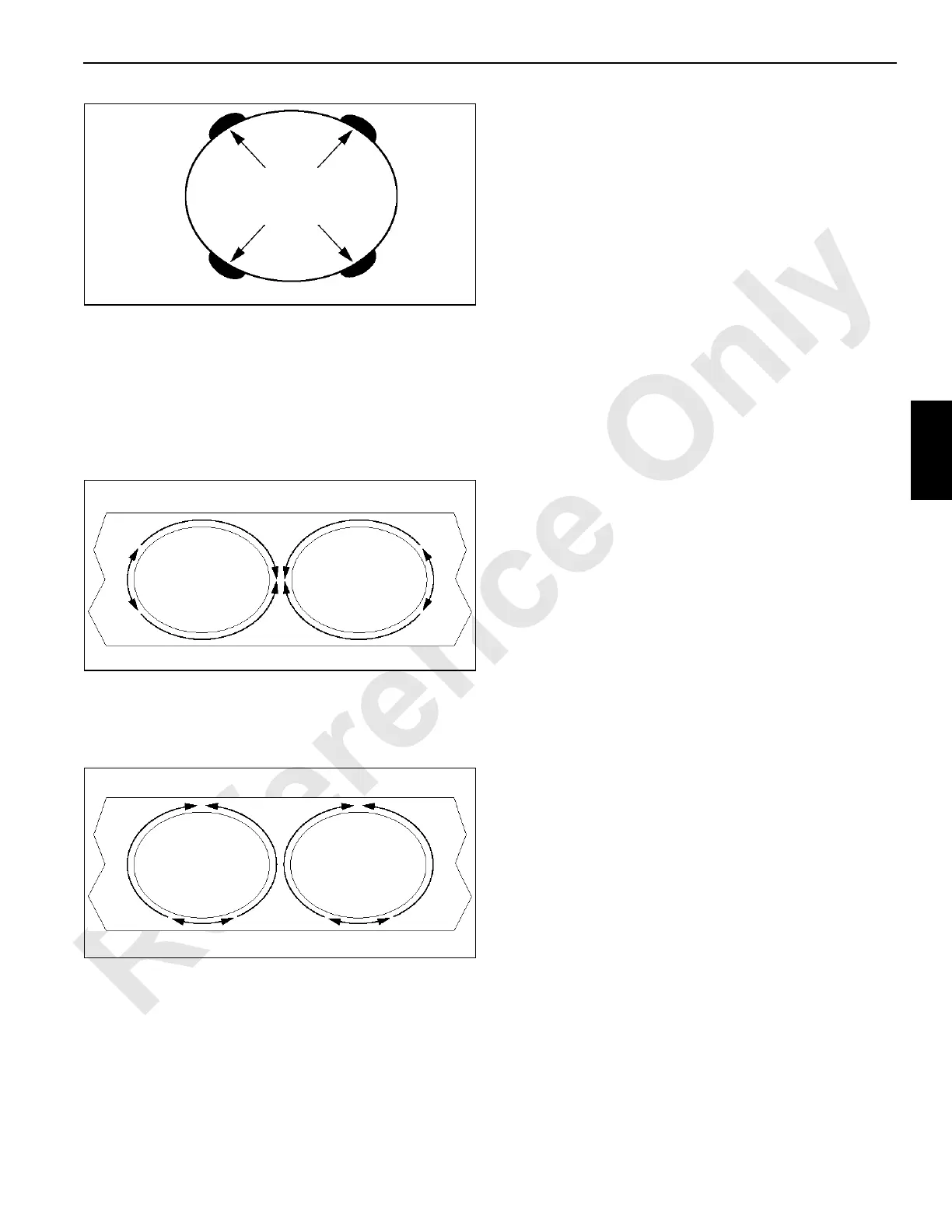

b. Use the following sequence for vertical welding. The

weld pass shall start at the 6:00 O’clock position and

end at the 12:00 O’clock position (Figure 4-21).

NOTE See Figure 4-24 for pass placement.

Weld profiles shall be smooth and blend gradually into

the base metal. Undercut shall not exceed 0.010 in (0.25

mm) deep on any lacing-to-chord joint. No piping

porosity is allowed in any weld repairs.

12. Use the following preheat and interpass temperatures:

• Minimum of 150°F (66° C)

• Maximum of 350°F (177° C)

NOTE All welders are required to monitor minimum and

maximum interpass temperatures by use of

temperature sticks. Apply heat evenly to avoid spot

heating any one area.

13. Use the weld size dimensions recorded during Lacing

Replacement step 1 on page page 4-18 to determine the

weld size for the replacement lacings. Refer to

Figure 4-24 for weld size and pass placement. The

finished weld must match the profile and size of the

corresponding lacings.

No excessive weaving is allowed. The Maximum bead

width is 5/16 in (8 mm).

14. Allow all finished welds to cool slowly to ambient

temperature.

15. Visually inspect for proper workmanship and correct

weld size. M.T. or P.T. inspect for soundness 48 hours

after welding is completed.

Do not use the lattice section during the 48 hour wait

period.

NOTE The 48 hour wait period prior to the final M.T. or P.T.

inspection can be waived if welding was performed

by a qualified Manitowoc representative.

Any welder that has taken and passed

Manitowoc’s Boom Lacing Replacement Class

is considered qualified by Manitowoc

.

Manitowoc recommends the N.D.T personnel be

certified to A.S.N.T. Level ll.

16. Prime and paint the welded area.

17. Send all completed inspection reports to Manitowoc

Crane Care. If possible, digital photographs should be

taken and submitted with the inspection reports.

End Lacing Replacement

End Lacings are the lacings that are closest to the

connectors and run perpendicular to the chords as shown in

Figure 4-22.

The end lacings hold the back-to-back and diagonal

dimensions of the chords and connectors. It is critical that the

original manufacturing connector tolerance be maintained.

Removing these lacings without properly bracing the lattice

section will make it extremely difficult to pin the repaired

section to another section.

Only one lacing should be replaced at any given time to help

hold the dimensions of the chords and connectors. The

procedure for removing the end lacings from an insert is

different from the procedure for a top or butt lattice section.

FIGURE 4-19

Tack Weld these Locations Only

Tack Welds Must be

1-1/2 in (38,1 mm) Long

FIGURE 4-20

Horizontal and Overhead Welding Sequence

FIGURE 4-21

Vertical Welding Sequence

Loading...

Loading...