777 SERVICE MANUAL HYDRAULIC SYSTEM

Manitowoc Published 10-01-2012, Control # 045-08 2-11

2

Table 2-7

Split Flange Leakage

SAE Flare Connection

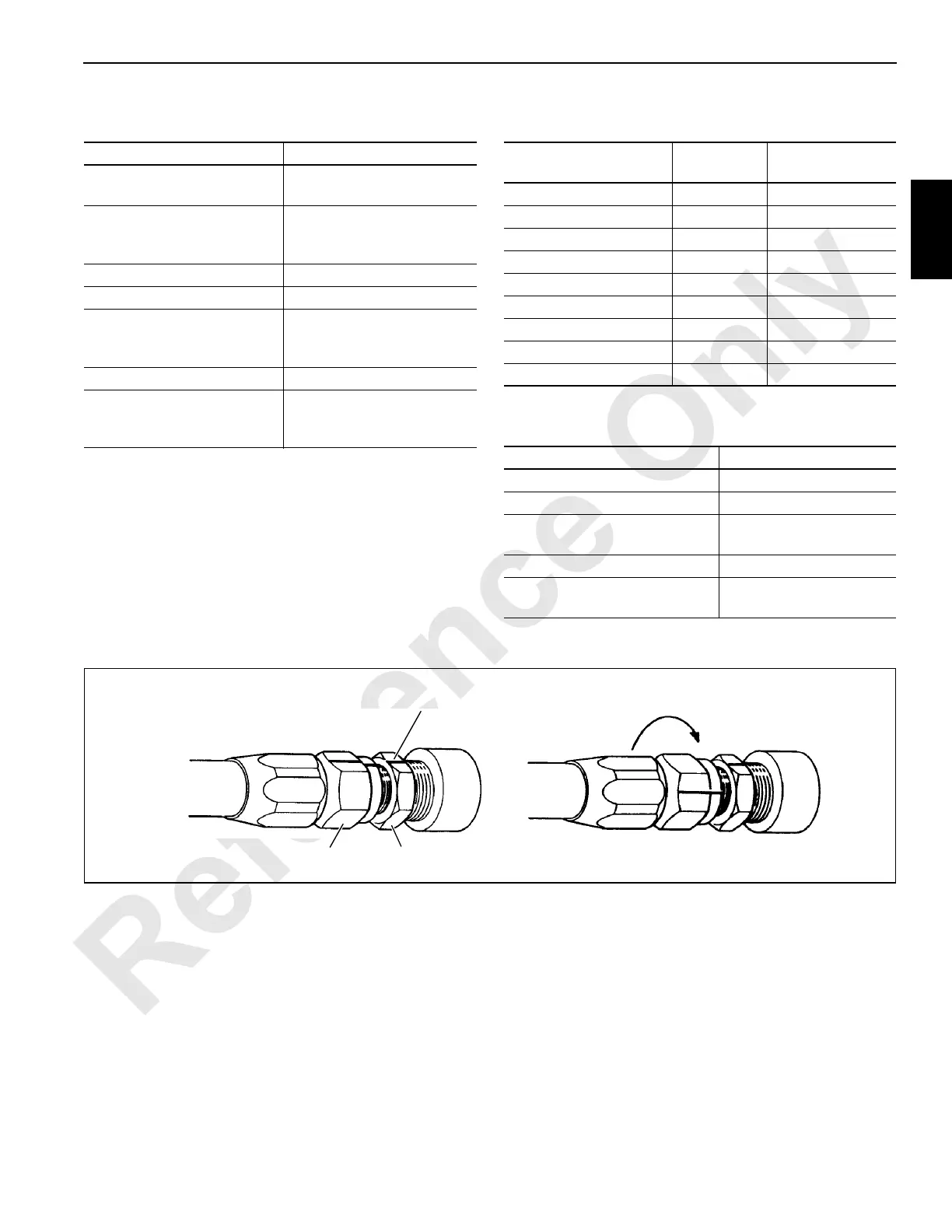

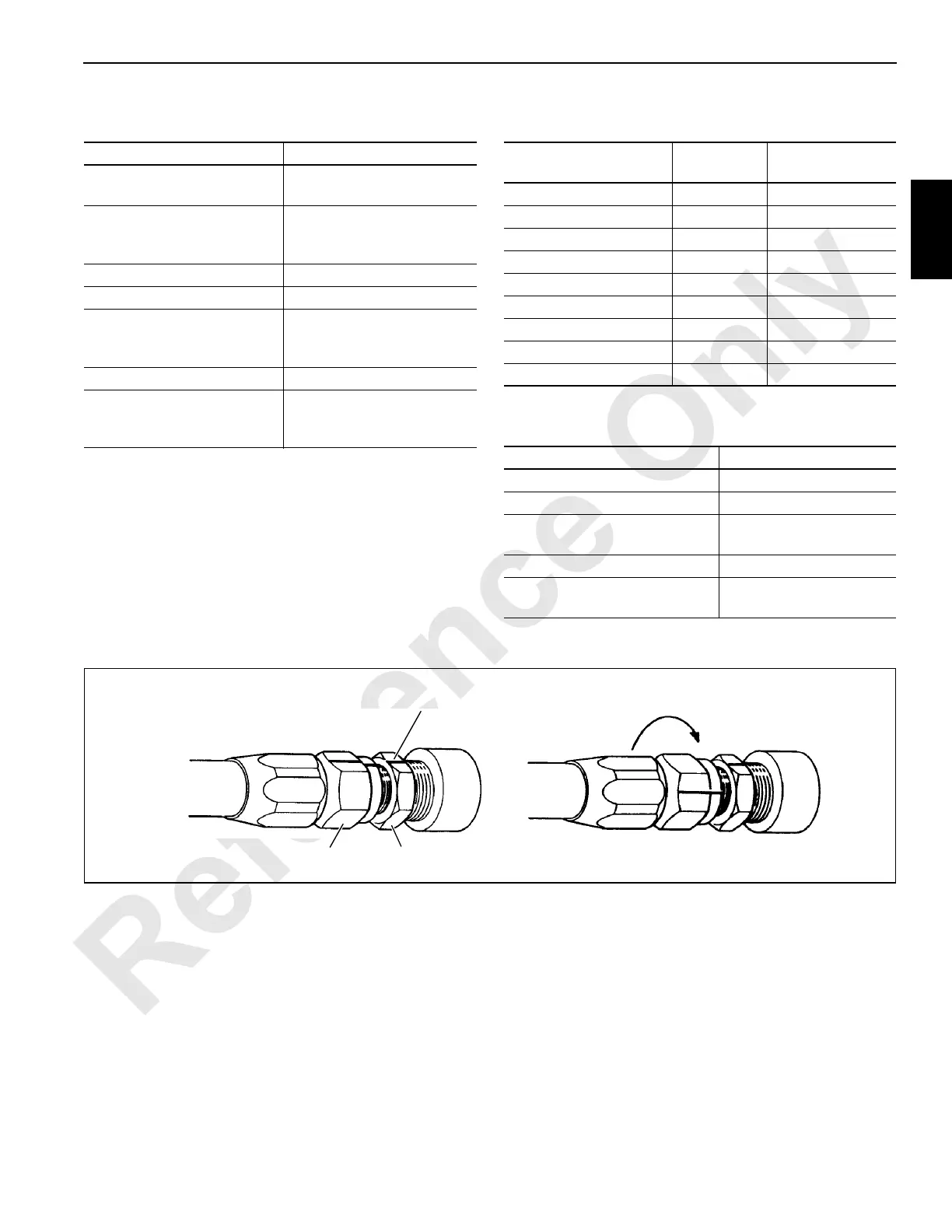

1. Tighten nut finger tight until sealing surfaces touch.

2. Mark a line (use felt pen or marker) on adapter and

extend it onto connector nut (Figure 2-11, View A).

3. Using wrenches, tighten connector nut the number of

flats shown in Table 2-8 (Figure 2-11, View B).

4. Misalignment of marks will show how much nut has

been tightened, and that it has been tightened.

Table 2-8

SAE 37° Flare Tightening

Table 2-9

SAE 37° Flare Leakage

Causes Cures

Flanges not tight.

Tighten bolts evenly to

proper torque.

Flanges tightened unevenly

causing extrusion of O-ring.

Replace O-rings. Tighten

bolts evenly to proper

torque.

O-ring cut. Replace.

O-ring wrong size. Replace with proper size.

Sealing surfaces not

smooth; scratched or

gouged.

Repair if possible or

replace parts.

Sealing surfaces dirty. Clean.

Flanges keep getting loose

in service.

Use SAE grade 5 bolts or

better. Retighten bolts after

system is hot.

Connector Nut Size

inch across flats

Fitting

Size

Adapter Flats

to Rotate

9/16 -04 2-1/2

5/8 -05 2-1/2

11/16 -06 2

7/8 -08 2

1 -10 1-1/2 – 2

1-1/4 -12 1

1-1/2 -16 3/4 – 1

2 -20 3/4 – 1

2-1/4 -24 1/2 – 3/4

Causes Cures

Joint loose. Tighten properly.

Sealing surfaces dirty. Clean.

Sealing surfaces not smooth;

scratched or gouged.

Replace faulty parts.

Sealing surfaces cracked. Replace faulty parts.

SAE 45° parts used with SAE

37° parts.

Use only SAE 37° parts.

Turn connector nut required

number of flats (Table 2-8)

S108

FIGURE 2-11

Connector

Nut

Adapter

Line

View A

View B

Loading...

Loading...