Manitowoc Published 10-01-2012, Control # 045-08 1-65

777 SERVICE MANUAL INTRODUCTION

1

Auxiliary Hoist Rotation Indicator

Whenever the auxiliary drum rotates, auxiliary drum speed

sender completes a circuit to the PC that activates rotation

thumper in control handle. This causes rotation thumper to

move up and down with a varying frequency that conveys the

rotational speed of the drum to the operator.

Auxiliary Drum Pawl System

The ratchet and pawl mechanism provides a positive means

of locking the position of auxiliary drum. The pawl system

operates independently and is controlled by a 2-position

double throw switch located on the front console.

The pawl should be used to maintain loadline locations,

especially when the crane is in the park position or left

unattended. Likewise, the front and rear drums should be

used for locking the corresponding drum in position when not

in use. The auxiliary drum pawl when selected to be

operated must be disengaged before it can be rotated

downward because the PC will not command release of the

brake by energizing HS9 and command the auxiliary pump

EDC to stroke the auxiliary pump in the down direction.

Should the pawl switch be accidentally activated, the PC

program opens the circuits to the auxiliary drum brakes. The

auxiliary drum brakes then apply.

Auxiliary Hoist Off

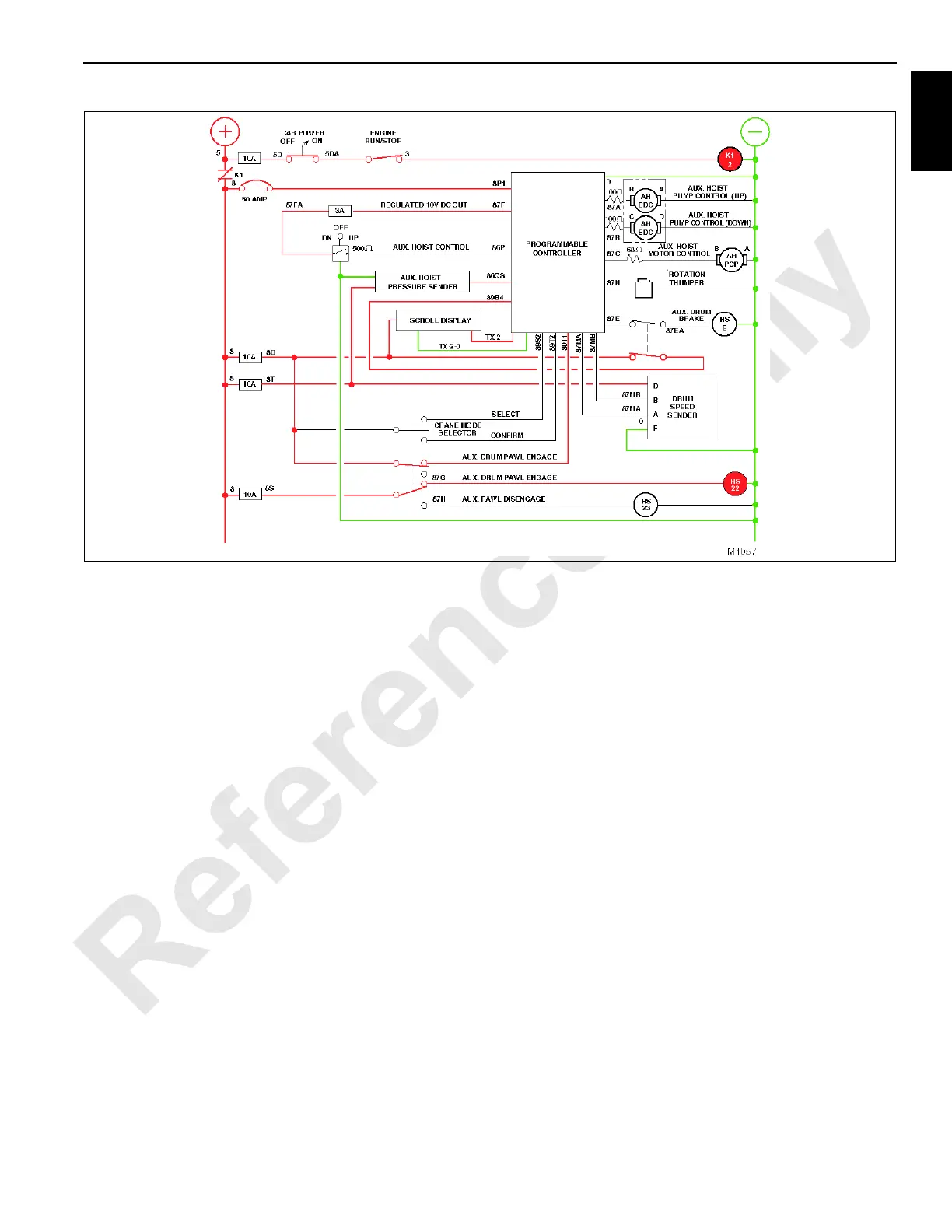

See Figures 1-46 and 1-47 for following procedures.

When auxiliary hoist control handle, located on the right

console in the operator’s cab, is in the off position, the handle

neutral switch is open, the PC receives no voltage from the

handle, and the PC opens the circuits to the auxiliary hoist

pump EDC, auxiliary hoist motor PCP valve, and auxiliary

drum brake hydraulic solenoid HS9. Because these circuits

are open, auxiliary hoist pump does not stroke, auxiliary

hoist motor remains at low speed, and auxiliary drum park

brake remains spring-applied to prevent the auxiliary drum

from turning.

Auxiliary Hoist Raise

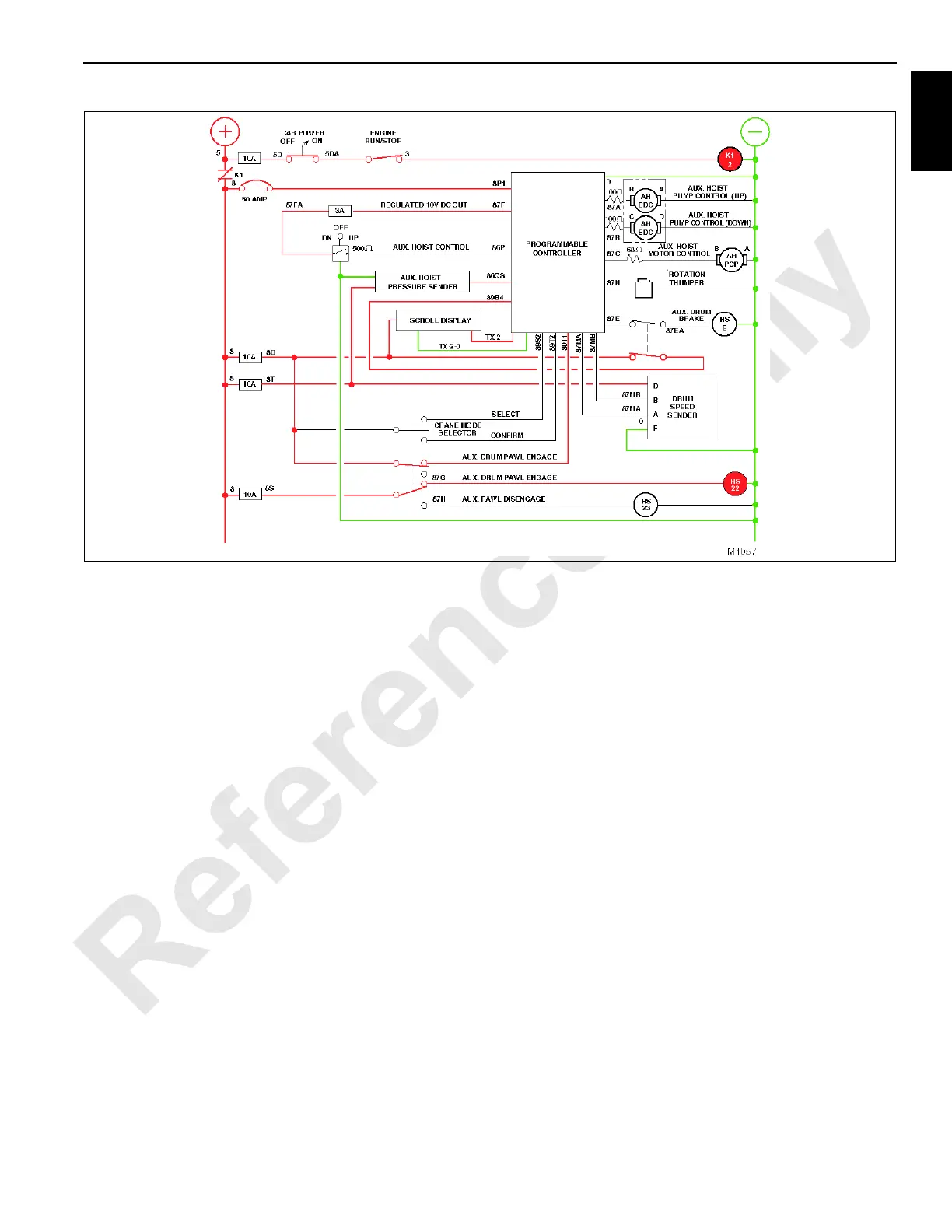

See Figures 1-48 and 1-49 for following procedures.

When control handle is pulled back for up operation, the

handle neutral switch closes, completing a regulated voltage

circuit from the handle potentiometer to the PC. The PC

interprets the signal for speed and direction and closes

regulated voltage circuits to the auxiliary hoist pump (up)

EDC, auxiliary hoist motor PCP and auxiliary drum park

brake hydraulic solenoid HS9. These circuits will close only if

the auxiliary drum park switch is off, applicable operating

limit switches are closed, and no system or operating faults

are present.

PC programming requires auxiliary hoist pump to stroke

before the auxiliary drum park brake is released. This

ensures adequate pressure is present to hold the load after

full release of the park brake. The regulated voltage to the

auxiliary hoist pump (up) EDC tilts the pump swashplate to

FIGURE 1-47

Loading...

Loading...