INTRODUCTION 777 SERVICE MANUAL

1-8 Published 10-01-2012, Control # 045-08

An accessory tandem gear pump supplies supercharged

filtered oil to the suction ports of some of these pumps,

provides oil to establish cylinder valve actuation, and

pressure oil to establish band brake release.

The PC controls each pump EDC in reaction to operator

commands through the system’s control handles. The PC

compares the handle commands with feedback information it

derives from continuous monitoring of the system’s sensors.

Data derived from this monitoring can be viewed on a digital

display screen in the operator’s cab by selecting the desired

information.

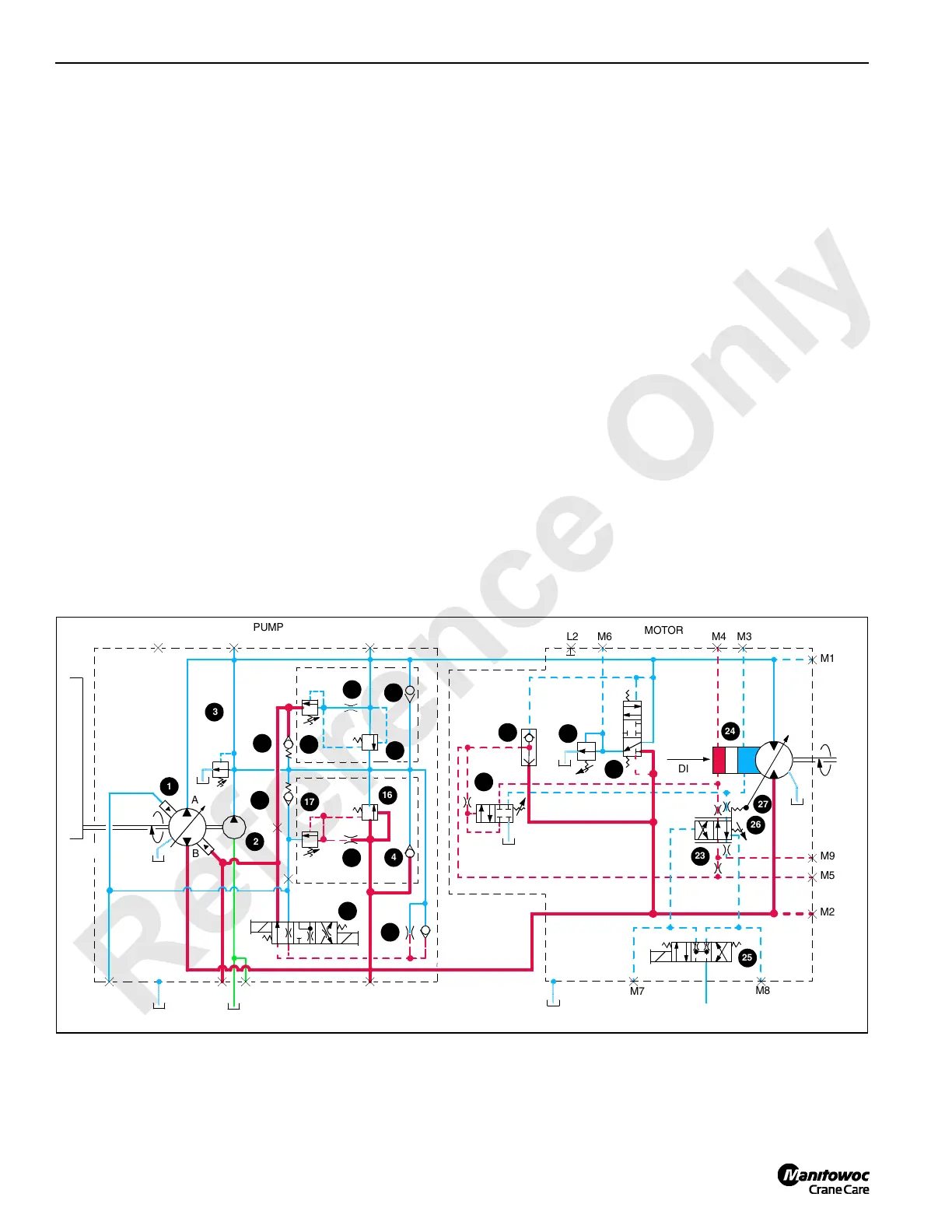

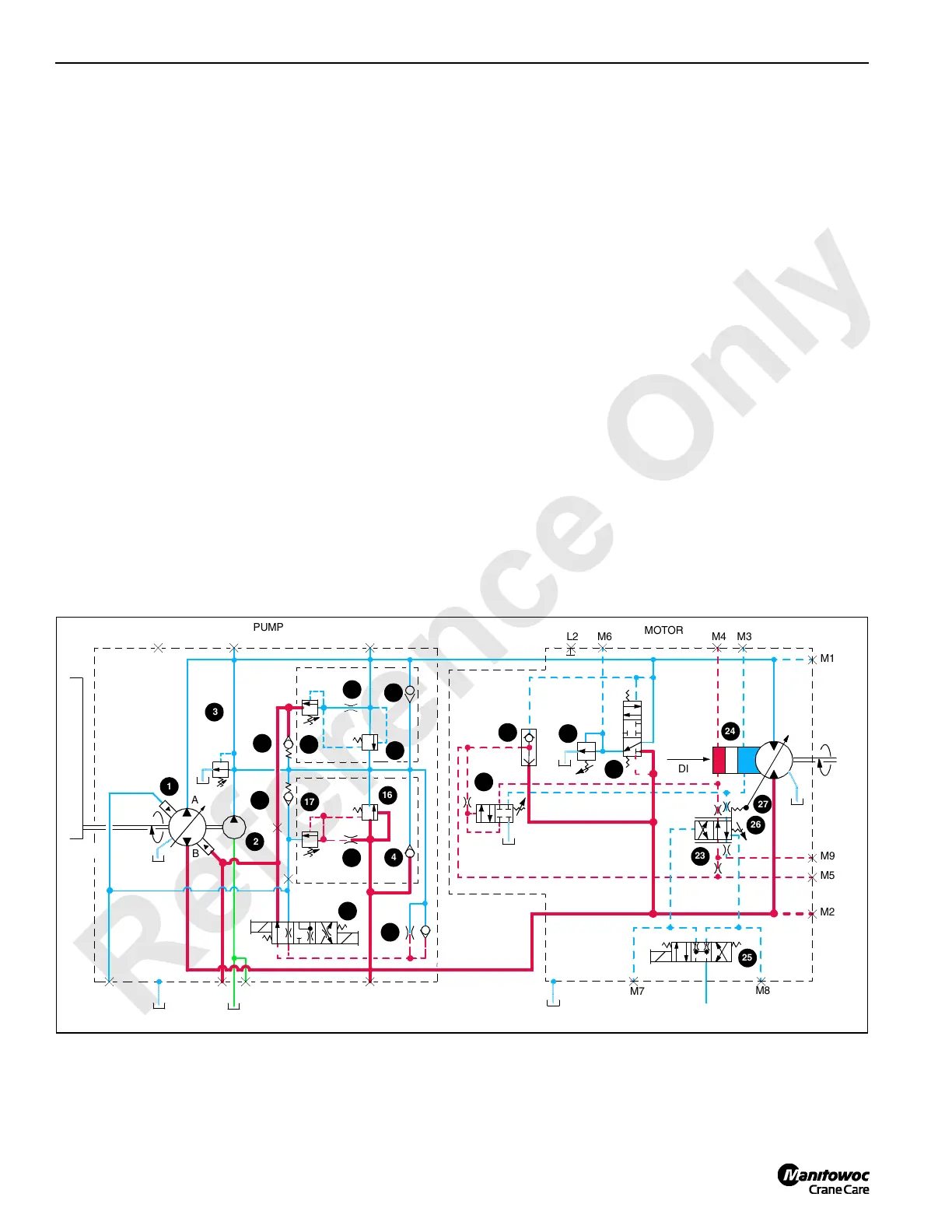

Hydraulic Pumps

See Figures 1-5 and 1-6 for following procedures.

Variable displacement, axial piston pumps are used in the

boom, front and rear hoists, swing, travel, and auxiliary hoist

(optional) systems. Each pump contains a cylinder block in

which the pistons are positioned axially around the drive

shaft, a tiltable swashplate against which the pistons ride, a

servo mechanism that tilts the swashplate, and two

multifunction valve cartridges.

Pump displacement is dependent upon the speed at which

the engine drives the pump through the pump drive gearbox

and the angle at which the swashplate is tilted. The engine

provides the horsepower available for work, while the

swashplate tilt provides speed control. An electrical hand

throttle sets engine speed; temporary increases are

accomplished with an electrical foot throttle.

The pump’s external EDC sets the amount and direction that

the swashplate is tilted by internal servo control cylinder.

Tipping direction establishes the direction that the oil flows

from the pump to the system actuator. This determines the

direction of motor rotation or cylinder movement.

A gerotor type gear pump is internally mounted on the end of

each system pump’s drive shaft. Charge pump (2) draws oil

directly from the hydraulic tank’s suction manifold or filtered

make-up oil. The charge pump delivers it to the closed-loop

at approximately 350 psi (24 bar) depending upon load and

engine speed and the setting of charge pump relief valve (3).

The charge oil provides oil cooling, positive pressure

maintenance in the low-pressure side of the loop, control

pressure for the pump swashplate servo mechanism, and

make-up oil for replacement due to internal leakage. From

the charge pump, the oil flows to charge flow make-up check

valves (4) in the multifunction cartridge, and passes over the

check valve on the low side of the loop. It combines with oil

returning from the system actuator and enters the system

pump.

In the system pump, the oil pressure holds each piston in

turn against the face of the swashplate as the engine rotates

the cylinder block.

FIGURE 1-5

M1002

(23 bar)

340 PSI

T2

T3

A

MAX.

P

U

M

P

D

R

I

V

E

B

B

A

A

DC

EGFD

OUTPUT

INPUT

PUMP

MOTOR

B

A

M8

M7

M3M4M6

L2

M9

M2

M5

M1

25

1

3

24

23

27

26

16

17

2

4

DISP.

T1

21

20

19

16

4

21

17

18

18

28

22

30

29

Loading...

Loading...