Manitowoc Published 10-01-2012, Control # 045-08 1-9

777 SERVICE MANUAL INTRODUCTION

1

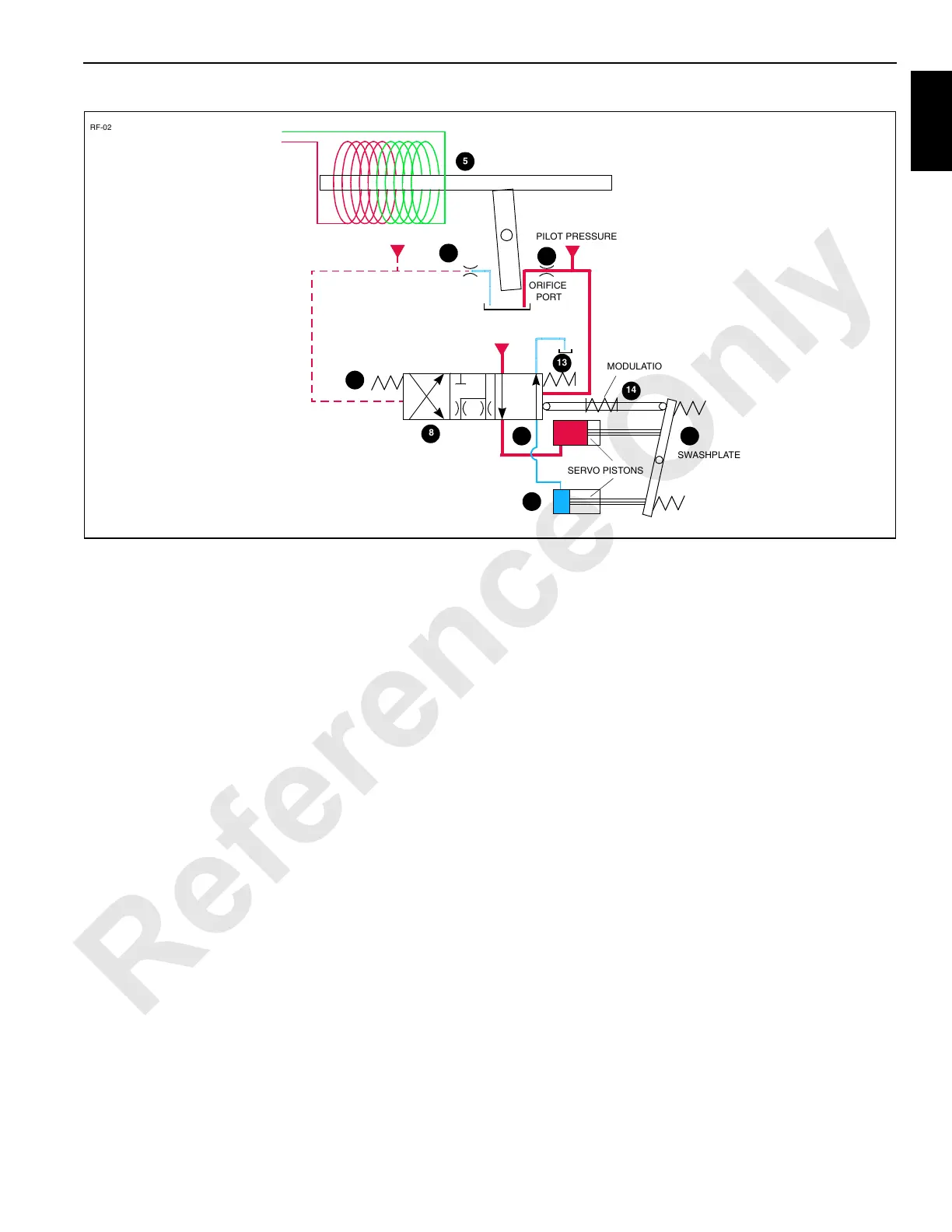

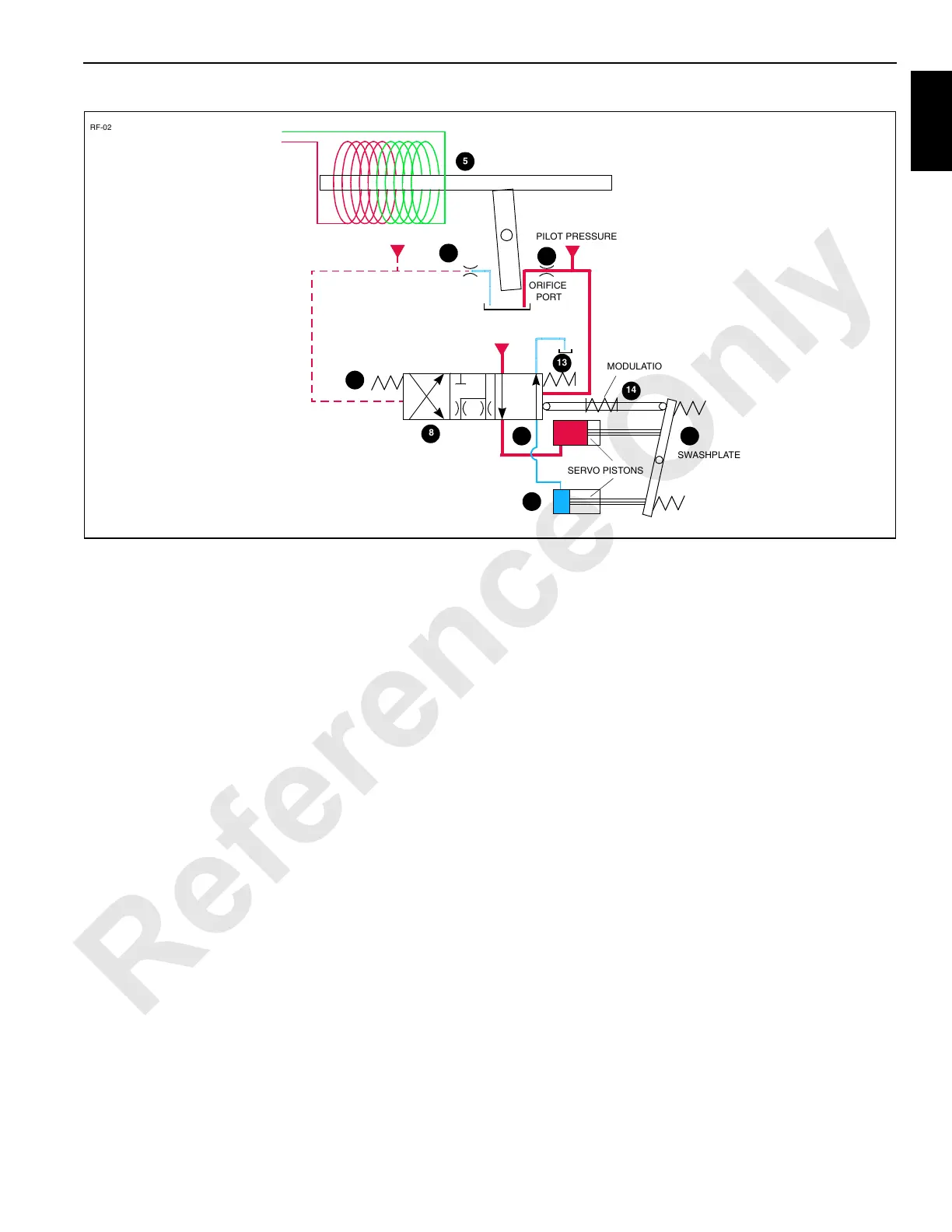

The PC transmits a command signal to one of the two coils in

the EDC via two of the four EDC connector pins. The first pin

energizes the coil. The current travels through the coil and

returns to the connector as negative charge through the

second pin. The polarity changes for opposite stroke

direction and positive current returns to the coil through the

second pin and back to negative through the first pin. This

charge cycle causes armature (Figure 1-6) to become more

magnetized, initiating its movement to begin blocking orifice.

The increasing blockage of orifice causes a larger pressure

increase in right port than in left port, resulting in a pressure

imbalance across spool. This pressure imbalance

overcomes the resistance of spring and initiates the

movement of spool causing internal servo control cylinder to

pressurize and servo oil to be routed to tank. This movement

causes swashplate to shift, and initiate the flow of oil out of

the pump. As swashplate shifts, spring chamber is pulled

opposite the direction of spool with linkage. This actuation

centers and maintains spool in a neutral position until the 16

psi (1.1 bar) preset pressure of spring is reached.

Because the swashplate is now tilted, the pistons are

reciprocated within the cylinder block as the block rotates.

The lengthening stroke of each piston draws returning oil into

the cylinder; as the stroke shortens, the oil is pumped out of

the pump cylinder to the motor cylinders at system pressure.

Note that when the swashplate is not tilted, there is no output

from the pump.

The amount that the swashplate is tilted determines the

amount of oil that is pumped to the motor or cylinder.

Increasing the swashplate tilt increases the stroke length,

causing more oil to be pumped to the system motor or

cylinders.

At this point, pressure develops within the closed-loop

system while the resistance of the load on the system

actuator is overcome. When movement begins, the volume

displacement of the pump maintains the actuator speed.

More flow from the pump operates the actuated system

faster to perform the desired activity.

Since each system pump operates in a bi-directional closed-

loop circuit, the pumps contain two different multifunction

valve cartridges, each of which consists of system relief

valve (16, Figure 1-5), make-up check valves (4), and

pressure limiting valve (17) which protect the crane’s

hydraulic system from excessive pressure and heat buildup.

When the preset system pressure is reached in the loop, the

multifunction valves limit system pressure by causing the

pump to destroke and/or allowing oil to transfer from the high

pressure side of the loop to the low pressure side.

In the travel pump’s main hydraulic loop, the system relief

make-up check valve, and pressure limiting sections of the

multifunction valve will respond when the preset relief

pressure at port B is reached. At this time, the oil pressure

actuates the spring in pressure limiting valve (17), shifting its

spool to open an exhaust path for the oil. Since servo check

valves (18) are spring loaded with an opening pressure of

750 psi (52 bar), the oil flows through the exhaust port of

displacement control valve (19). The exhaust port of

displacement control valve is restricted by orifices (A),

causing flow to pressurize servo control cylinder (1) and

destrokes the pump’s swashplate to limit the system

FIGURE 1-6

SWASHPLATE

SERVO PISTONS

PILOT PRESSURE

ORIFICE

RF-02

PORT

MODULATION

ORIFICE

PORT

SPRING

CONTROL VOLTAGE

ARMATURE

SPOOL

PILOT PRESSURE

PILOT PRESSURE

SPOOL

SPRING

FROM CONTROLLER

7

11

9

6

10 12

13

14

8

5

Loading...

Loading...