TROUBLESHOOTING 777 SERVICE MANUAL

10-26 Published 10-01-2012, Control # 045-08

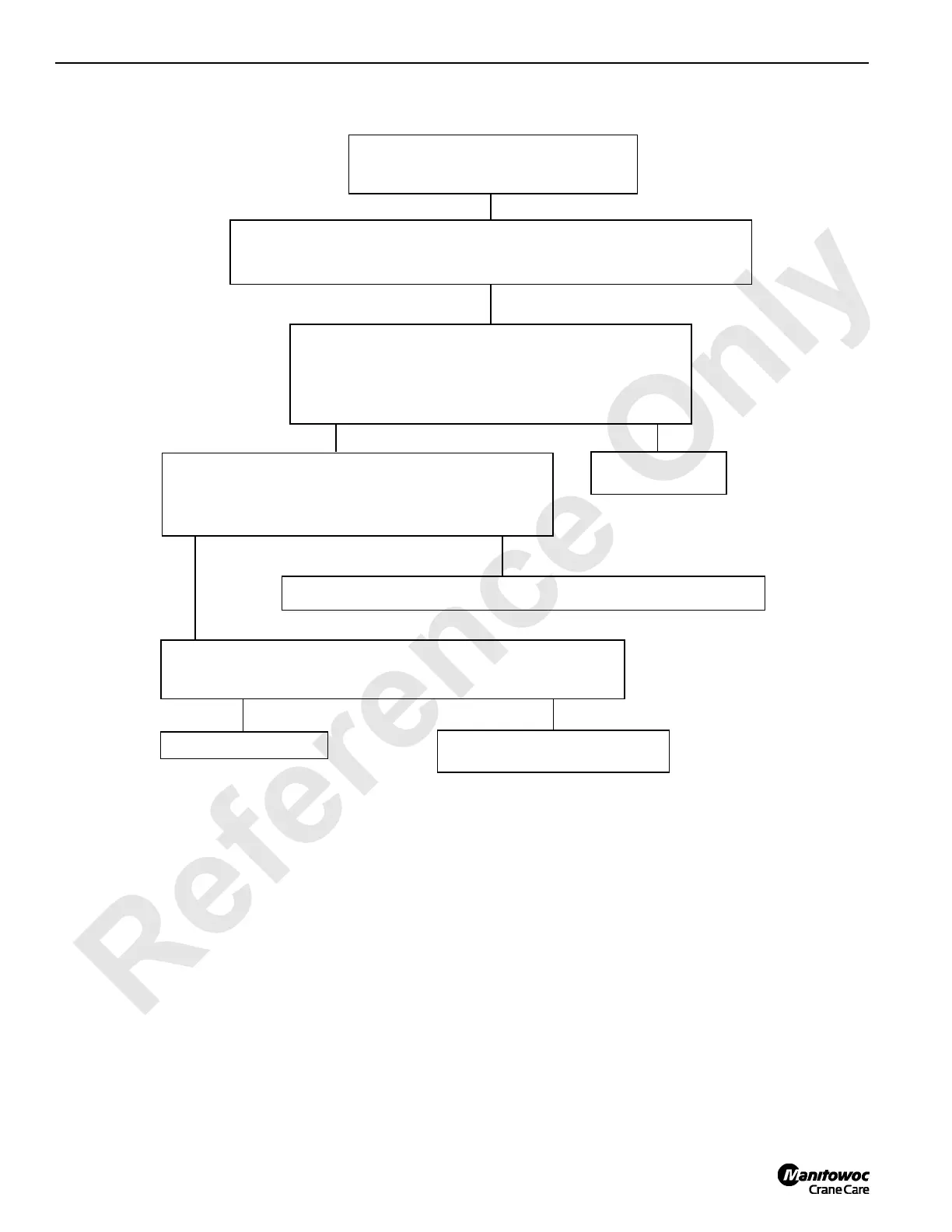

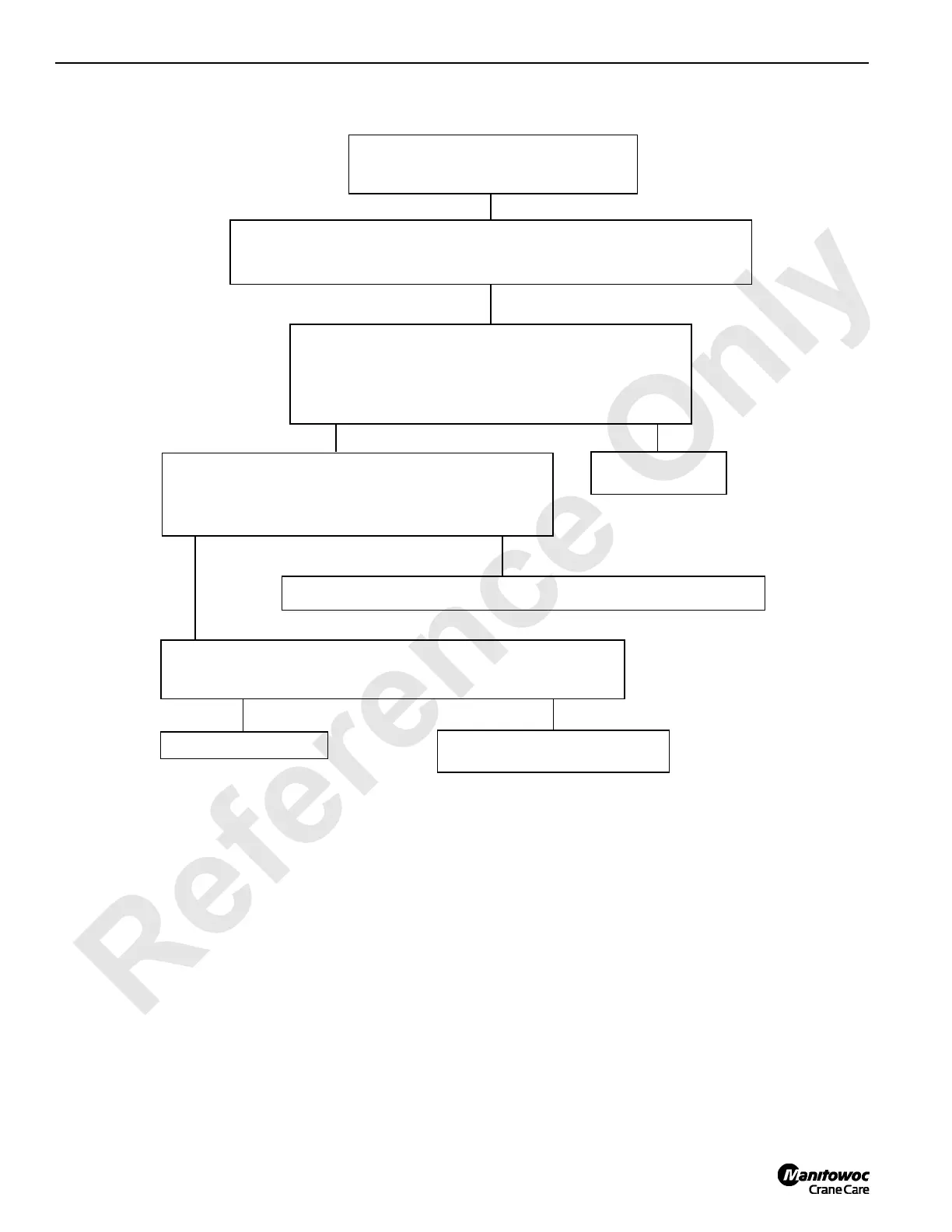

CHECKS

Check for damage to pawl or pawl linkage. Check for pawl

or pawl actuator/cylinder for freedom of movement.

Problem 24

A load drum pawl is not operating correctly.

POSSIBLE CAUSES

Mechanical hang-up; No hydraulic pressure; No voltage to front or rear drum motor;

No voltage to auxiliary drum pawl solenoid; Cylinder failure; Motor failure.

No Damage

Damage

Repair damage.

Test and adjust.

Check and replace pawl fuse F6 (wire 8S) if open. Check pawl switch wiring.

Move load drum pawl selector switches and verify pawl

solenoid is enabled. One solenoid valve is always enabled.

Check auxiliary drum hydraulic cylinder for pressure at cylinder ports.

Voltage

No Voltage

Pressure

No Pressure

Check hydraulic circuit components.

Replace items as required.

Repair or replace cylinder.

Loading...

Loading...