INTRODUCTION 777 SERVICE MANUAL

1-22 Published 10-01-2012, Control # 045-08

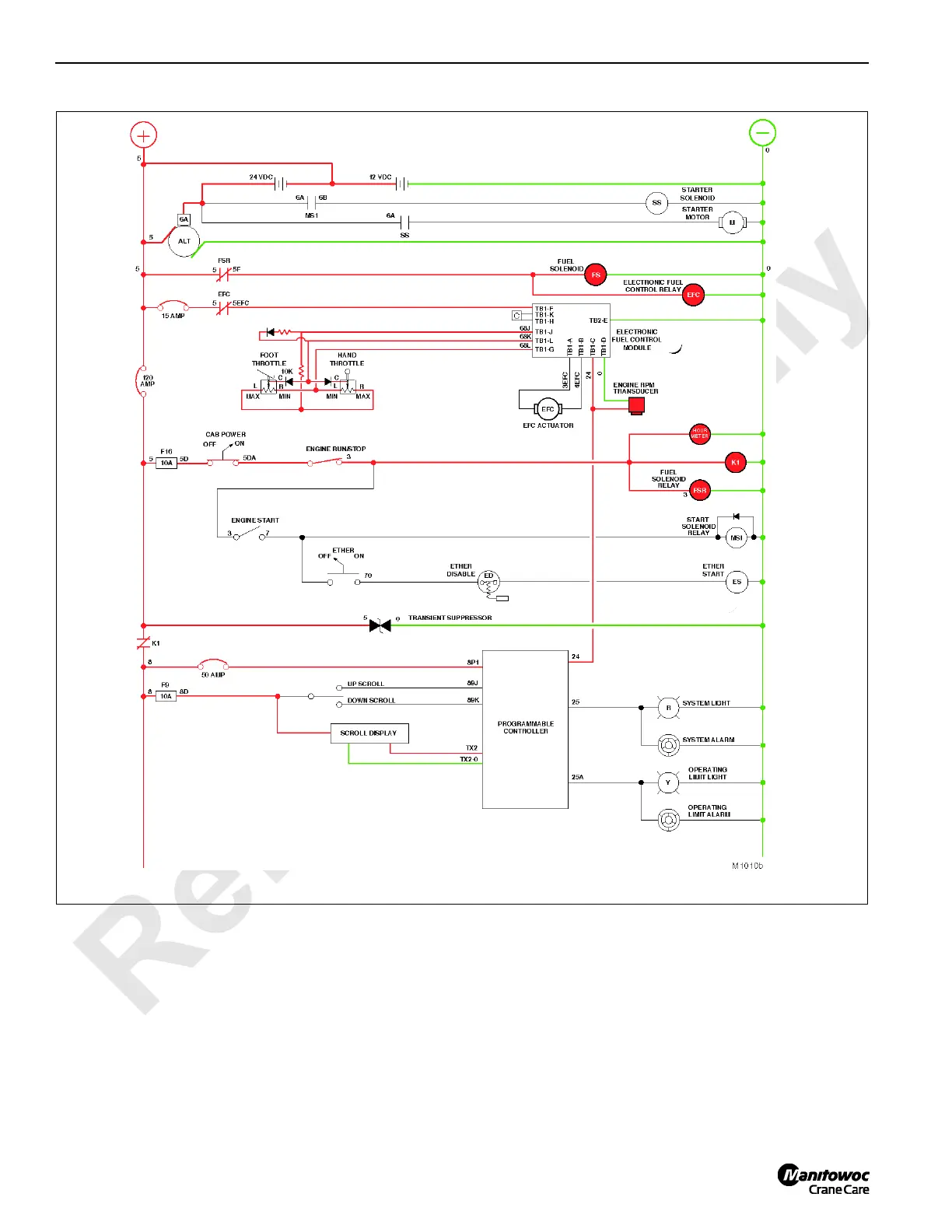

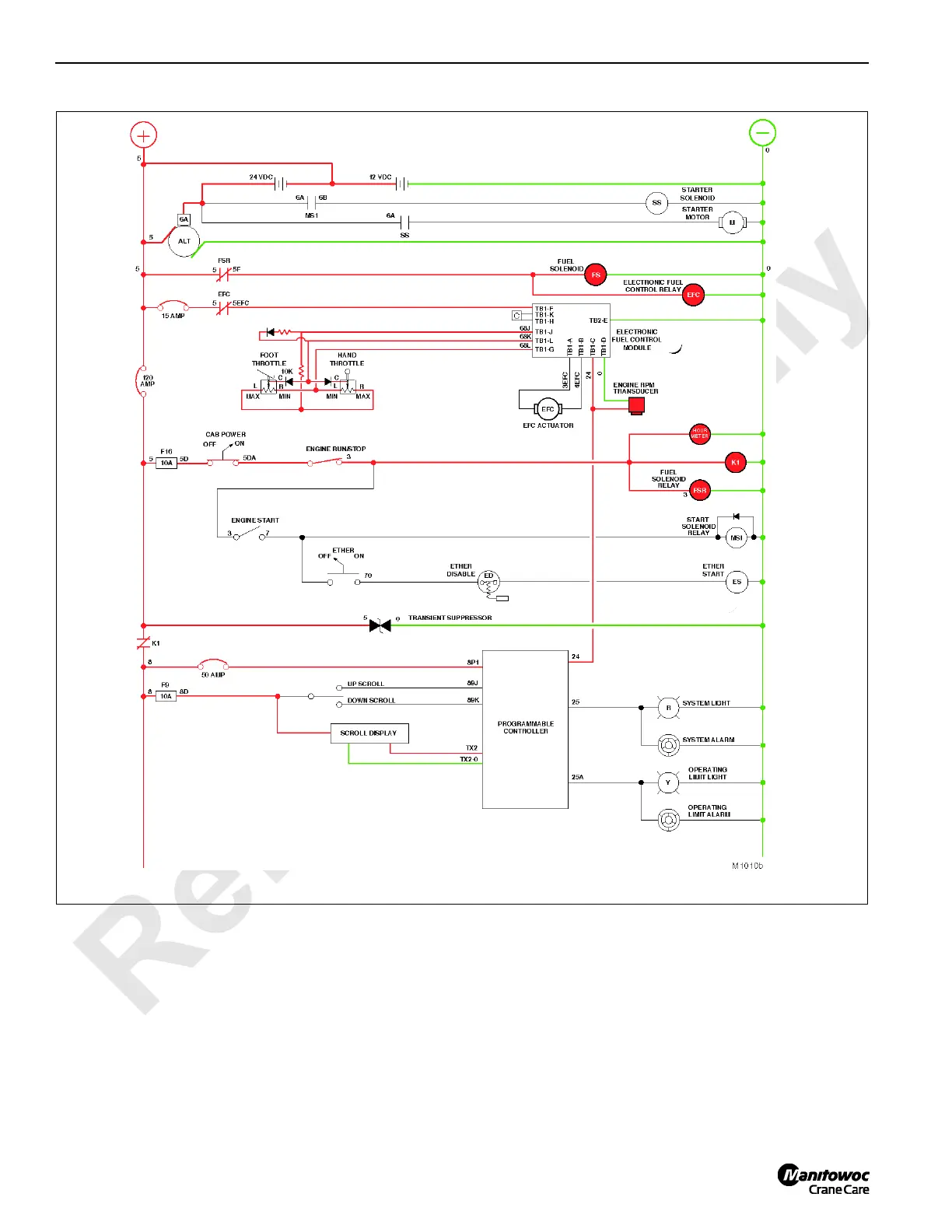

When detecting a difference in the two signals, module

changes the current input to EFC actuator, causing the

actuator shaft to rotate in the appropriate direction to either

increase or decrease the fuel flow and engine speed and

power.

In addition to communicating with EFC module, the

transducer also provides an AC electronic signal to the PC.

The PC interrupts the incoming signal and provides engine

speed data for the scroll display. The PC will also limit travel

speed by maintaining maximum travel motor hydraulic

displacement when track movement is initiated below 1800

engine rpms and will resume the lower travel speed when

engine speed falls below 1500 rpm.

Activating engine start switch also provides power to ether

starting aid switch. In order to prime the ether injection

mechanism for assisting with crane startup, engine start

switch and ether switch must be depressed and held at the

same time to complete the circuit to ether start switch ES and

ether disable switch ED. Releasing ether switch after

approximately three seconds of priming, discharges the

ether into the engine air inlet manifold and disables the

injection mechanism.

FIGURE 1-13 continued

Loading...

Loading...