INTRODUCTION 777 SERVICE MANUAL

1-30 Published 10-01-2012, Control # 045-08

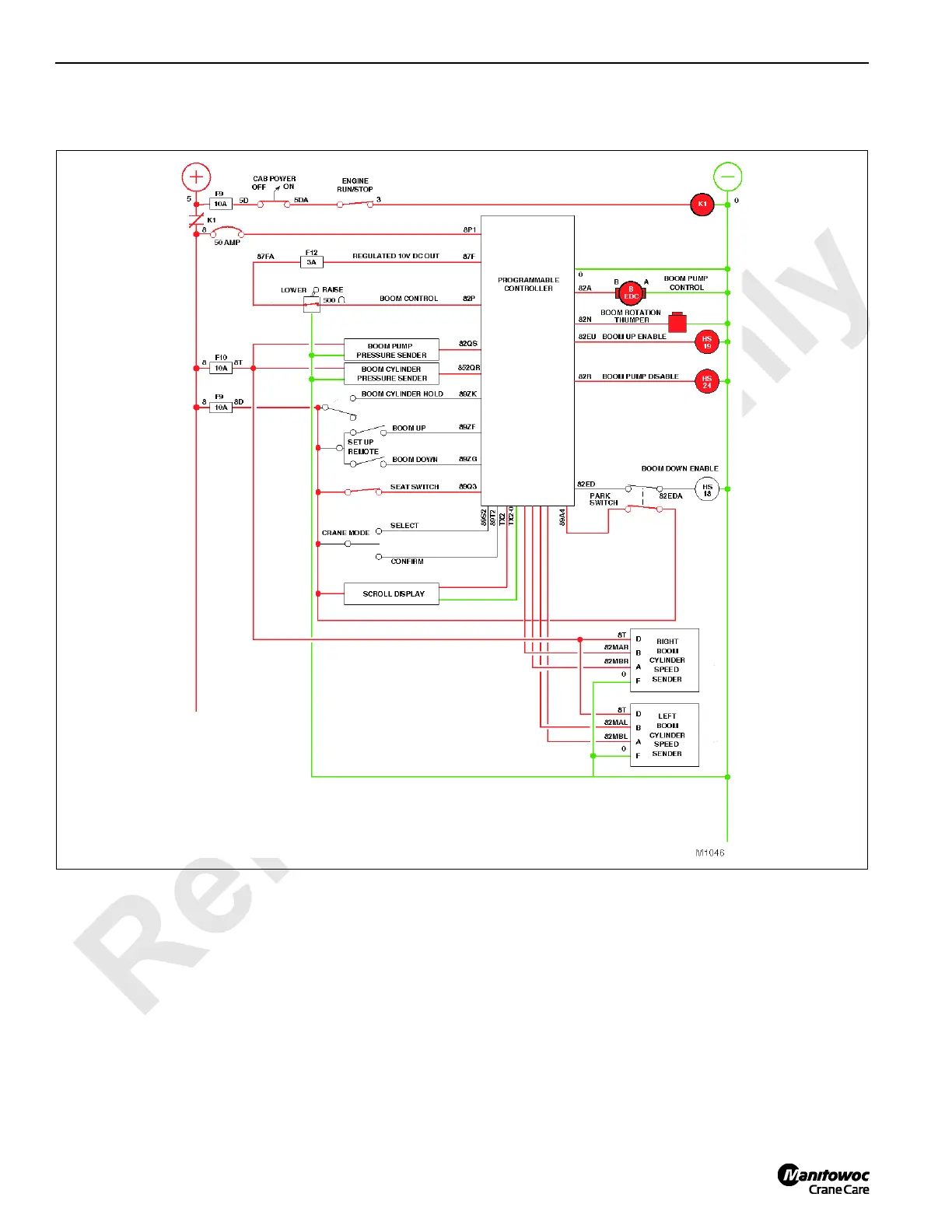

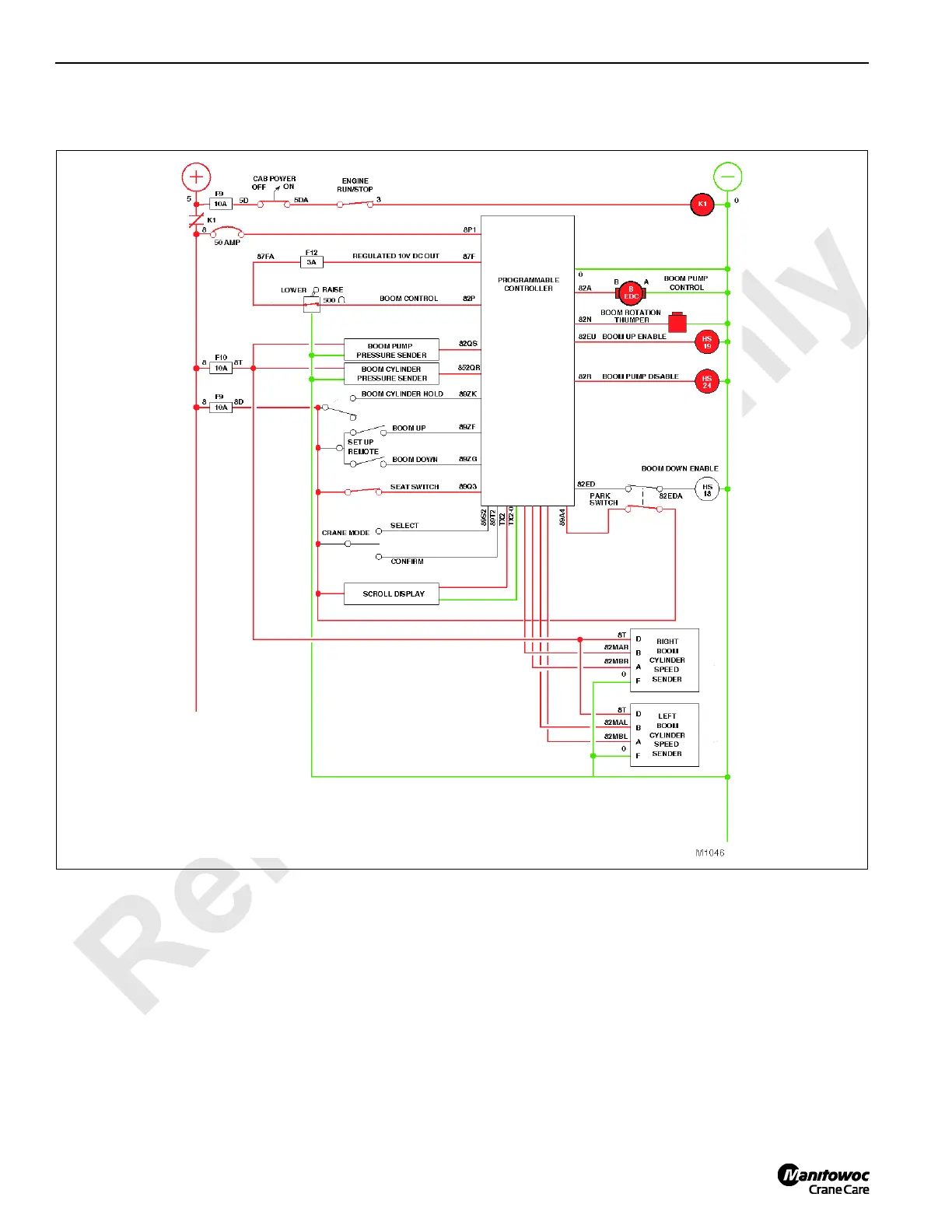

PC are blocked by the neutral switch on the control handle.

Unless the Boom Cylinder Hold switch is on, the boom pump

does not stroke and the boom load holding valves maintain

the position of the boom cylinders.

FIGURE 1-18

Loading...

Loading...