106 User Manual Version 3.1

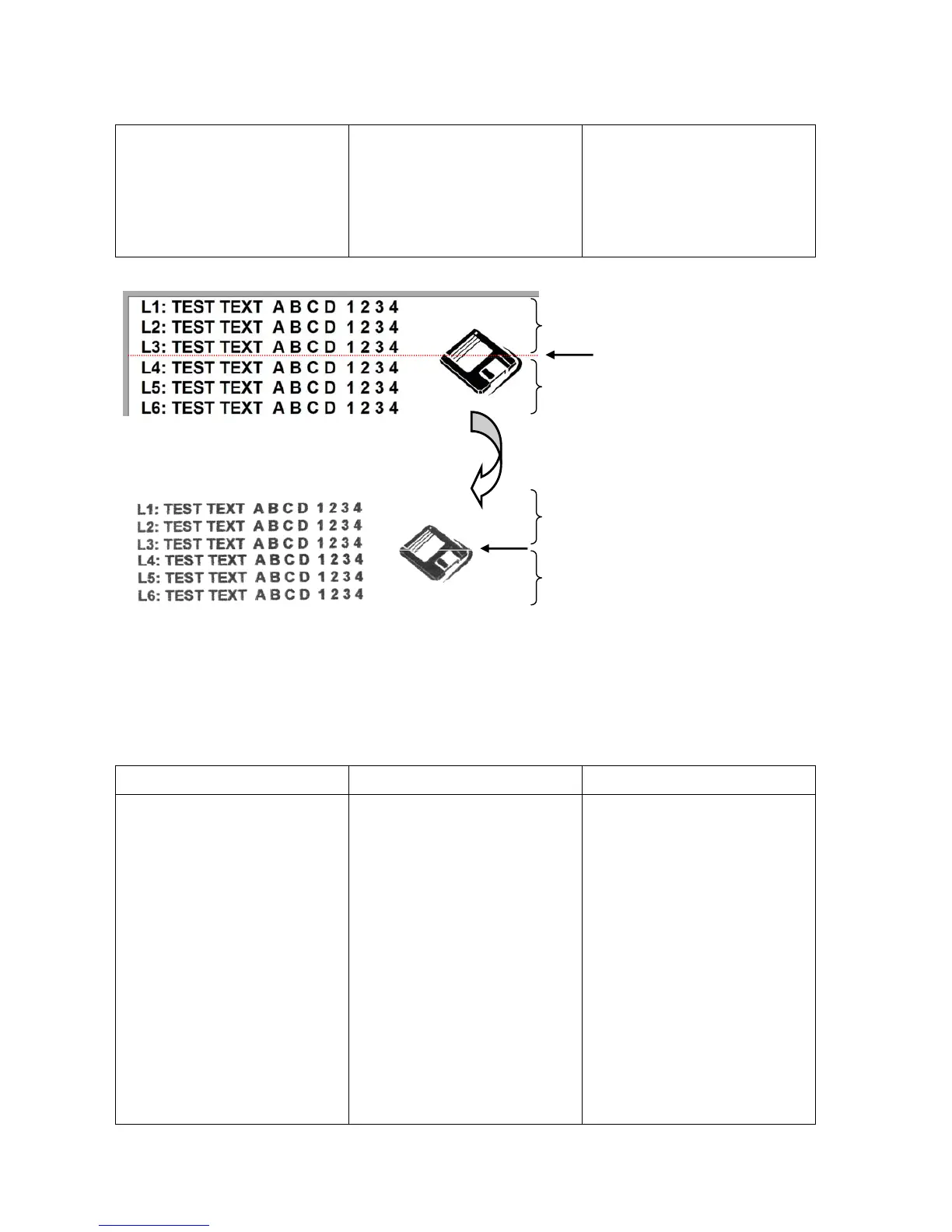

between the print area of

two carriage movements

(see Figure 55).

correct.

PRINTER CONFIG. ->

ADJUSTMENTS ->

ADJUSTMENT STEPS

• Check if the material

transport is setup

correctly.

Figure 55: White streaks in between two cartridges

Pos: 76 /Bedienungsanlei tungen/Geräte spezi fisch/Druc ker/Troubleshooting (al l printers)/Printi ng/8.2.1_Ü3_The pri nted ink doesn't dry on the substrate @ 3\mod_127980482 9363_912.doc @ 24149 @ 3

8.2.5 The printed ink doesn’t dry on the substrate

Condition Problem Solution

The used ink doesn’t dry fast

enough.

The printout looks partly

smeared.

The drying time is too short.

There is too much ink on the

printout.

The material-ink combination

is not suitable.

Reduce the print quality (e.g.

2x6dpi instead of 3x6dpi) to

decrease the amount of ink.

If available, put a conveyor

behind the printer to extend

the drying time.

Reduce the transport speed

to extend the drying time.

Try another kind of ink (see

9.1.1, on page 133). Vary

the material-ink

combinations.

If available, use an infrared

light dryer (ask your local

Neopost dealer).

Pos: 77 /Bedienungsanlei tungen/Geräte spezi fisch/Druc ker/8.x_Ü2_Error_Messa ges @ 2\mod_1265641574257 _912.doc @ 11615 @ 2

Preview of print layout in PC software

Print area of one cartridge movement

Print area of next cartridge movement

Actual printout with white streak

Print area of one cartridge movement

Print area of next cartridge movement

Loading...

Loading...