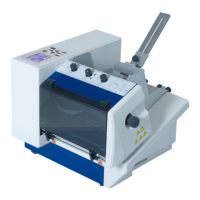

5.4 How to adjust the printer to the material thickness

To ensure a sharp, clean print quality and a safe material transport, you have to adjust the

printer to the material thickness. Set the thickness adjustment knob to the following scale

values:

Scale value Material thickness

0 0.1 mm – 0.4 mm

(e.g. empty envelope or 80 g/m² stock)

1 0.4 mm – 0.8 mm

2 0.8 mm – 2.0 mm

3 2.0 mm – 3.5 mm

4 3.5 mm – 5.0 mm

5 5.0 mm – 6.0 mm

If you don’t know the thickness of your material, you should adjust the printer as described

below:

• Open the transparent safety cover.

• Lift the transport rollers and the movable exit rollers by turning the thickness

adjustment knob (see Figure 16) to the maximum thickness (scale value “5”).

• Put one medium underneath the transport rollers (see Figure 17).

• Lower the transport rollers and the movable exit rollers by turning the thickness

adjustment knob until the medium sits tightly between the rollers (you must still be

able to move the medium!).

• Pull out the medium and close the safety cover.

Figure 16: Thickness adjustment knob

Loading...

Loading...