8-7

8-3 Troubleshooting

Troubleshooting

8

8-3 Troubleshooting

If an error occurs in the machine, determine the error conditions from the alarm indicator and

operating status, identify the cause of the error, and take appropriate countermeasures.

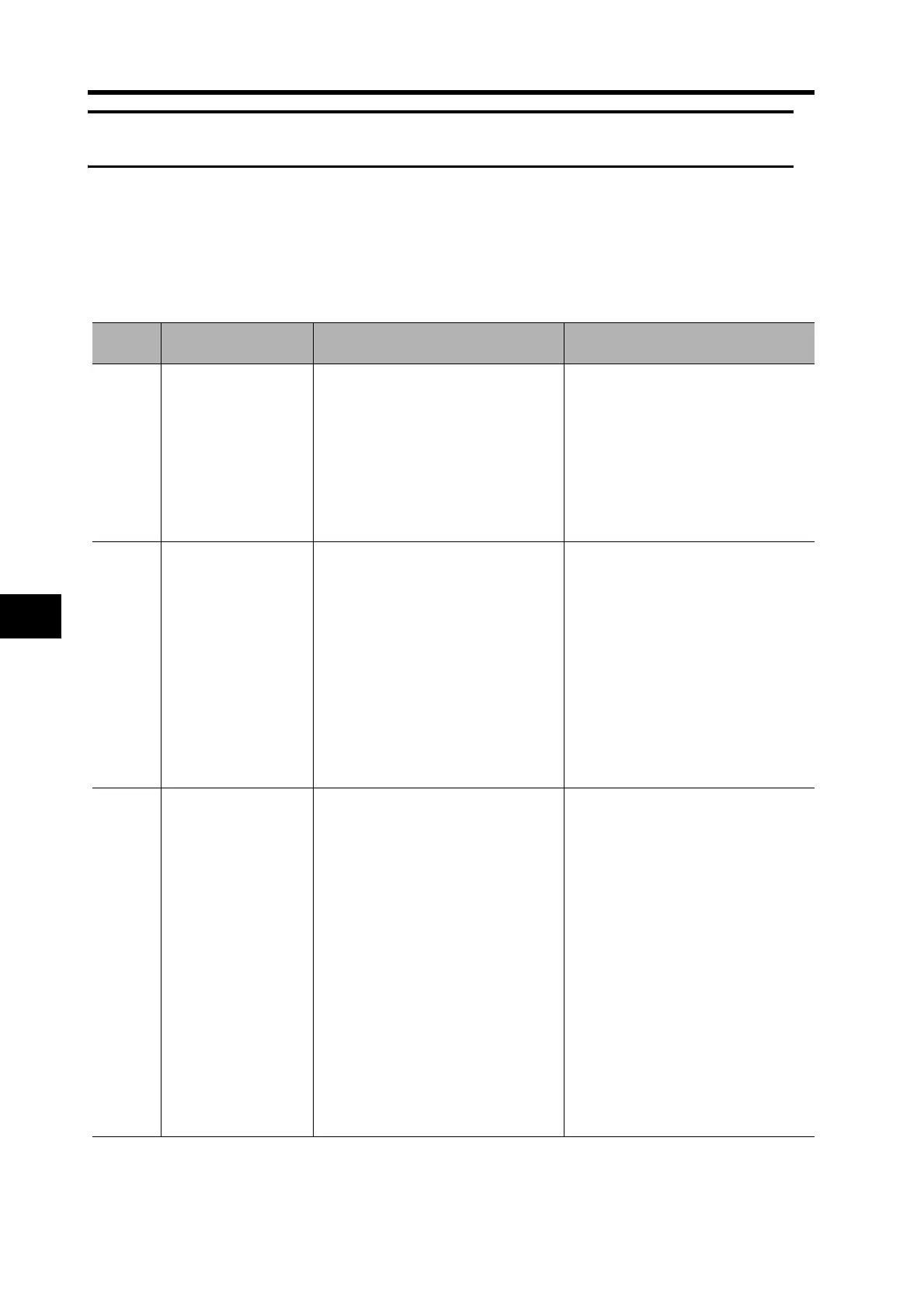

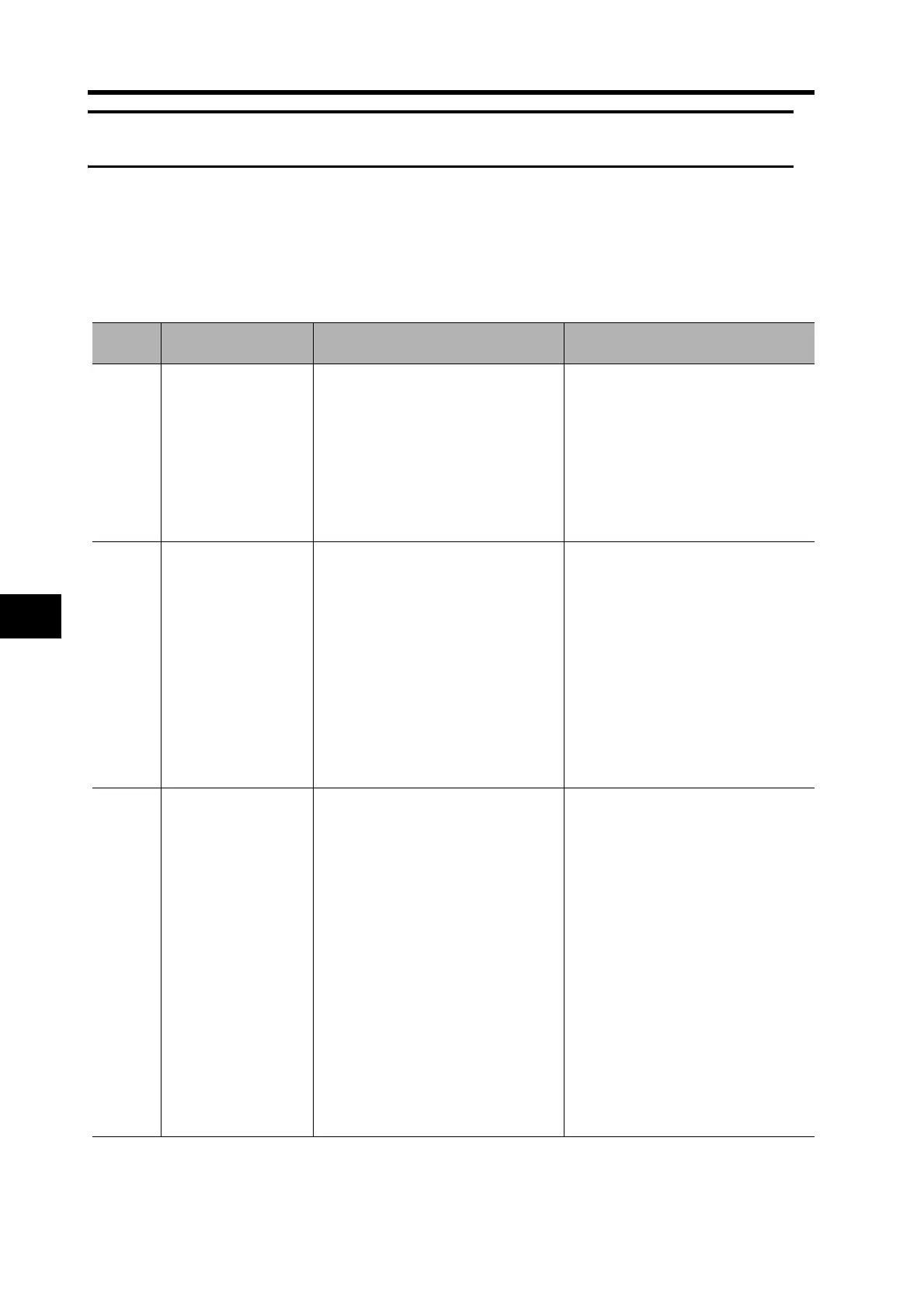

Error Diagnosis Using the Displayed Alarm Codes

Alarm

code

Alarm Name Cause Countermeasure

11

Control power supply

undervoltage

The voltage between P and N in the

control voltage converter has dropped

below the specified value.

1 The power supply voltage is low. A

momentary power failure occurred.

2 The power supply capacity is

insufficient. The inrush current at

power-ON caused the power

supply voltage to drop.

3 The Servo Drive has failed.

Measure the line voltage between

control power supply L1C and L2C.

1 Resolve the cause of the power

supply voltage drop and/or

momentary power failure.

2 Increase the power supply

capacity.

3 Replace the Servo Drive.

12 Overvoltage

The voltage between P and N in the

main circuit has exceeded the speci-

fied value. The power supply voltage is

too high. Phase advance capacitor

and/or UPS (uninterruptible power

supply) is causing a jump in voltage.

1 Regenerative energy cannot be

absorbed due to a disconnection of

the regeneration resistor.

2 Regenerative energy cannot be

absorbed due to the use of an

inappropriate external regeneration

resistor.

3 The Servo Drive has failed.

Measure and check the line voltages

between L1, L2, and L3 of the main

power supply. Input a correct voltage.

Remove the phase advance capacitor.

1 Measure the resistance for the

external regeneration resistor

between terminals B1 and B2 of the

Servo Drive, and check that the

reading is normal. Replace it if

disconnected.

2 Provide the necessary

regeneration resistance and

wattage.

3 Replace the Servo Drive.

13

Main power supply

undervoltage

With the Undervoltage Alarm Selection

(Pn065) set to 1, the main power

supply between L1 and L3 was

interrupted for longer than the time set

by Momentary Hold Time (Pn06D).

Alternatively, the voltage between P

and N in the main circuit dropped

below the specified value while the

Servo Drive was ON.

1 The power supply voltage is low.

2 A momentary power failure

occurred.

3 The power supply capacity is insuf-

ficient - The inrush current at

power-ON caused the power

supply voltage to drop.

4 Missing phase - A single-phase

power supply was used for a three-

phase Servo Drive.

5 The Servo Drive has failed.

Measure and check the line voltages

between L1, L2, and L3 of the main

power supply.

1 Resolve the cause of the power

supply voltage drop and/or

momentary power failure.

2 Check the setting for the

Momentary Hold Time (Pn06D).

3 Increase the power supply

capacity. Refer to the Servo Drive

specifications for the power supply

capacity.

4 Correctly connect the phases (L1,

L2, and L3) of the power supply.

Connect single-phase 100 V and

single-phase 200 V to L1 and L3.

5 Replace the Servo Drive.

Loading...

Loading...