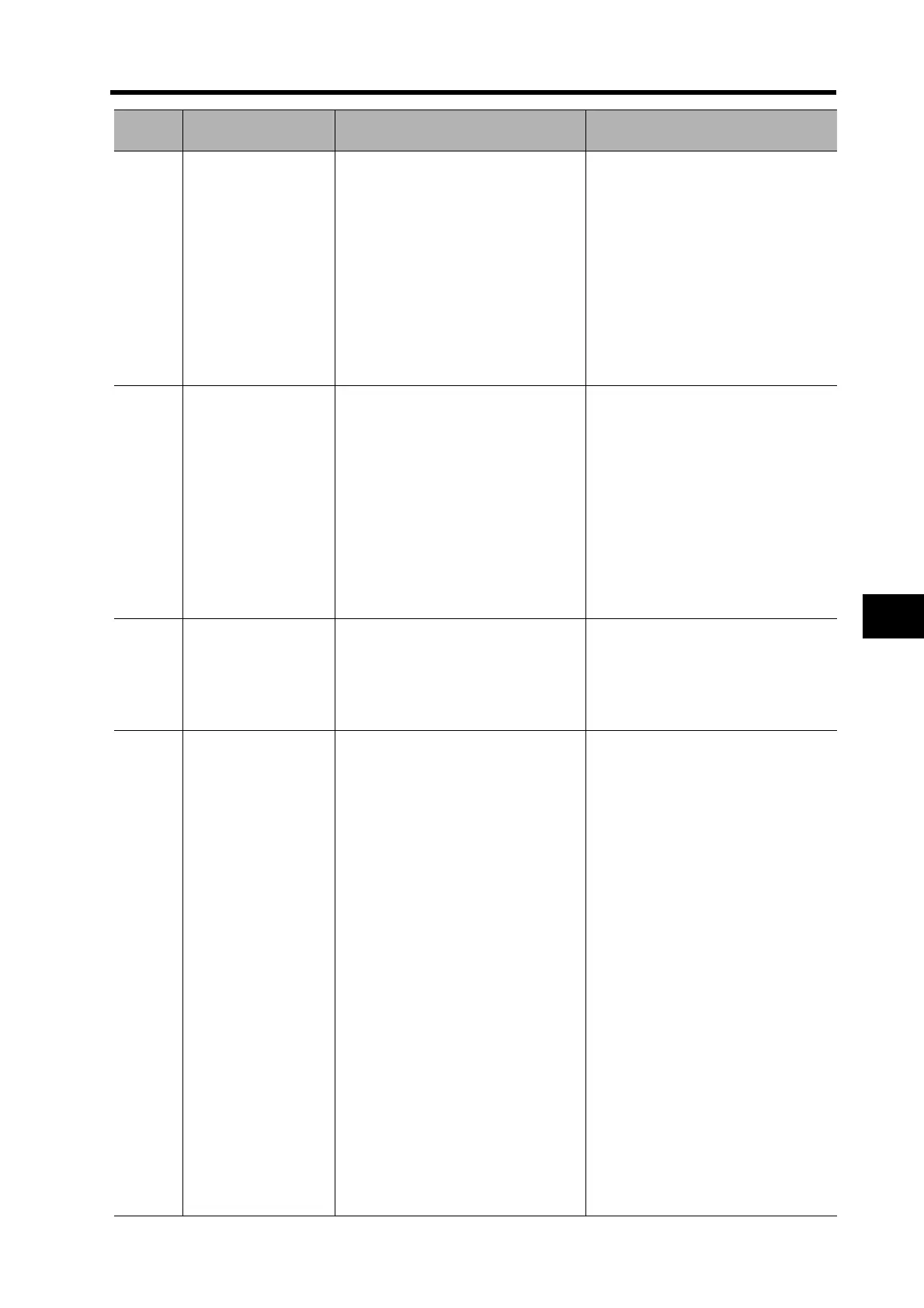

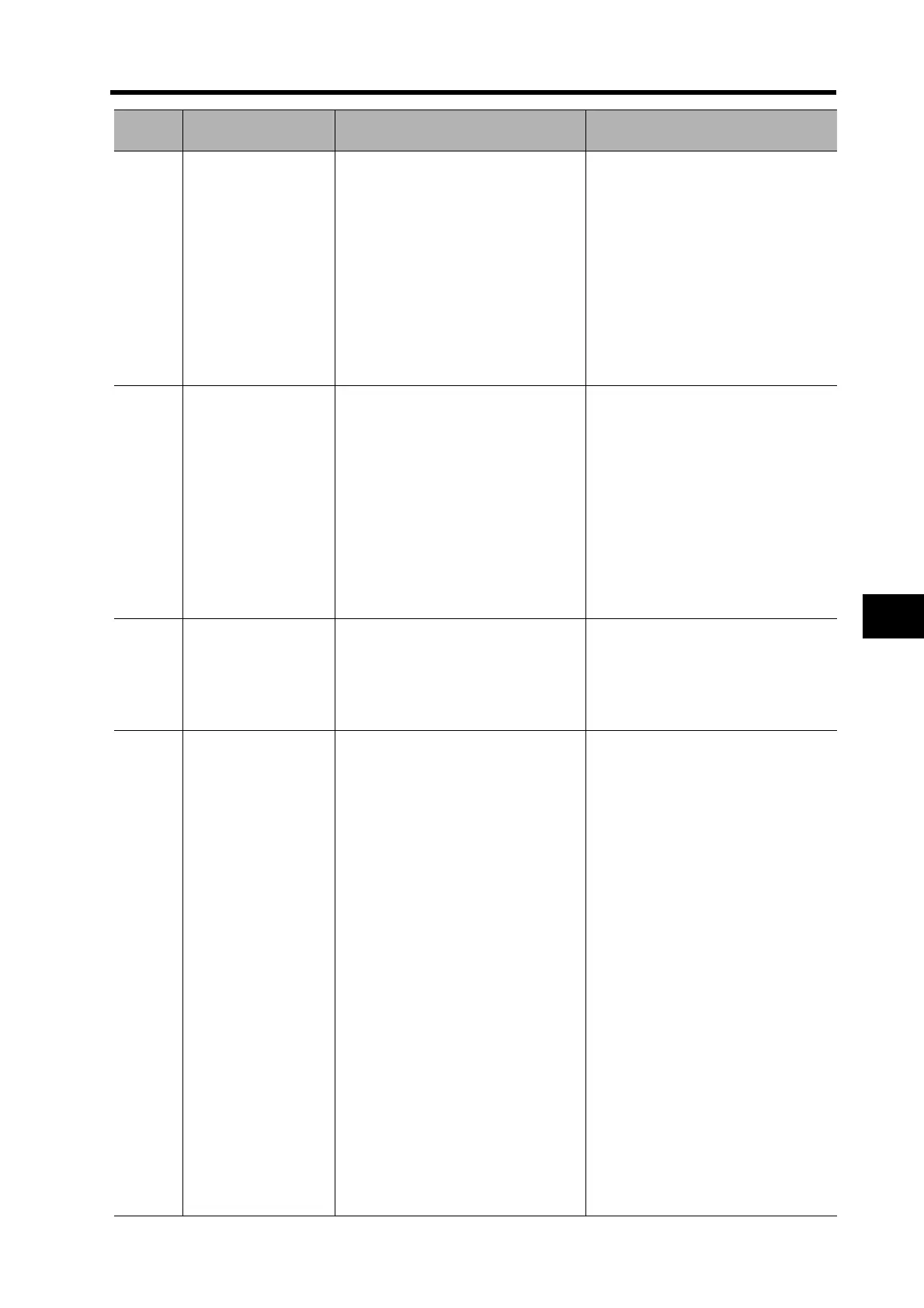

8-10

8-3 Troubleshooting

Troubleshooting

8

23

Encoder

communications data

error

Communications error occurred for the

data from the encoder. Mainly a data

error due to noise. The encoder line is

connected, but the communications

data is erroneous.

Check that the encoder power supply

voltage is within the range of 4.75 to

5.25 VDC. (If the encoder line is

long.)

If the Servomotor line and the

encoder line are bound together,

separate them.

Check that the shield is connected to

FG (frame ground), and that FG is

grounded.

Attach a ferrite core to the encoder

cable. Attach a radio noise filter to the

power cable.

24

Deviation counter

overflow

The number of position deviation

pulses exceeded the Deviation Count-

er Overflow Level (Pn209).

1 The Servomotor operation is not

following the commands.

2 The Deviation Counter Overflow

Level (Pn209) is set too low.

Calculate the deviation counter

value based on the command

speed and the position loop gain.

1 Use the speed monitor and torque

monitor to check that the

Servomotor is operating as

commanded. Check that torque is

not saturated. Check that the No. 1

Torque Limit (Pn05E) and the No. 2

Torque Limit (Pn05F) are not too

small.

Check by readjusting the gain,

increasing the acceleration /

deceleration times, and lowering

the speed with the reduced load.

2 Increase the setting for Pn209.

26 Overspeed

The rotation speed of the Servomotor

exceeded the setting of the Overspeed

Detection Level Setting (Pn073).

Check that excessive speed

commands have not been issued.

If overshoot is occurring due to

improper gain adjustment, adjust the

gain for the position loop and the

speed loop.

27 Command error

The operation command resulted in an

error.

1 Incorrect value in position

command.

·The amount of change in the

position command (value calculat-

ed with the electronic gear ratio)

exceeded the specified value.

·The travel distance required for

acceleration / deceleration,

calculated when starting

positioning, exceeded the

specified value.

2 A MECHATROLINK-II link was

established with the host while

executing a standalone operation

(normal mode autotuning, and jog

operation).

Note If the alarms are cleared

immediately after actuating

communications, this alarm

may be cleared immediately

after it has been issued, and

cannot be read.

3 Multi-turn data on the absolute

encoder was cleared via RS-232

communications after actuating the

MECHATROLINK-II link.

Check that the operation commands

are correct.

1 Review the operation commands

and settings.

Check the settings. For example,

check that the amount of change

for the position command is not too

large (i.e. interpolation function),

the backlash compensation

amount is not too large, the

backlash compensation time

constant is not too small, the

electronic gear ratio is not too large,

and the acceleration/deceleration

is not too small.

2 Do not actuate the network while

executing normal mode autotuning

and jog operation.

3 Alarm code 27 is issued when

clearing the multi-turn data on the

absolute encoder via RS-232

communications. This is for safety

purposes, not an error. When

executing the multi-turn clear

command via the network, an

alarm will not be issued, but be sure

to reset the control power supply.

Alarm

code

Alarm Name Cause Countermeasure

Loading...

Loading...