Chapter F - ADJUSTMENTS

Planmeca Compact i F-19

ELECTRICAL ADJUSTMENTS

Technical Manual

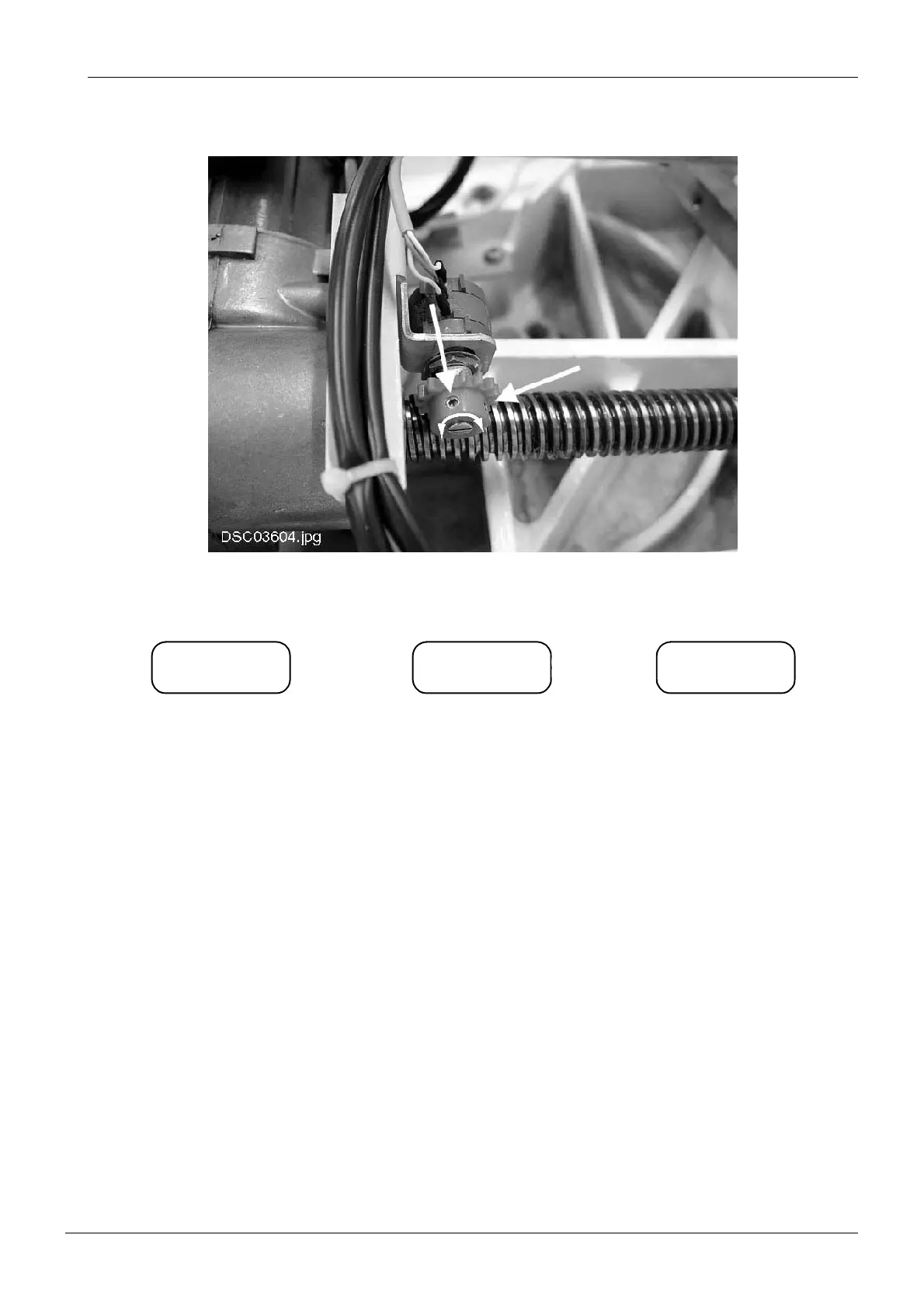

d) Loosen the two M3x6 DIN 916 screws at the side of the cog wheel of the sensor.

e) Rotate the axle of the sensor with a screwdriver until the two horizontal lines on the display

are in line.

f) Tighten the two M3x6 DIN 916 screws to secure the cog wheel into position.

g) Using the A key drive the backrest downwards and after the lowest position is reached

continue pressing the A key for approx. 2 seconds to drive the backrest to horizontal position.

Check that the spindle nut does not touch the cog wheel or potentiometer.

h) Drive the guiding nut past the calibration mark a couple of times to ensure that the sensor is

now calibrated correctly (the horizontal lines are aligned).

i) Exit service mode.

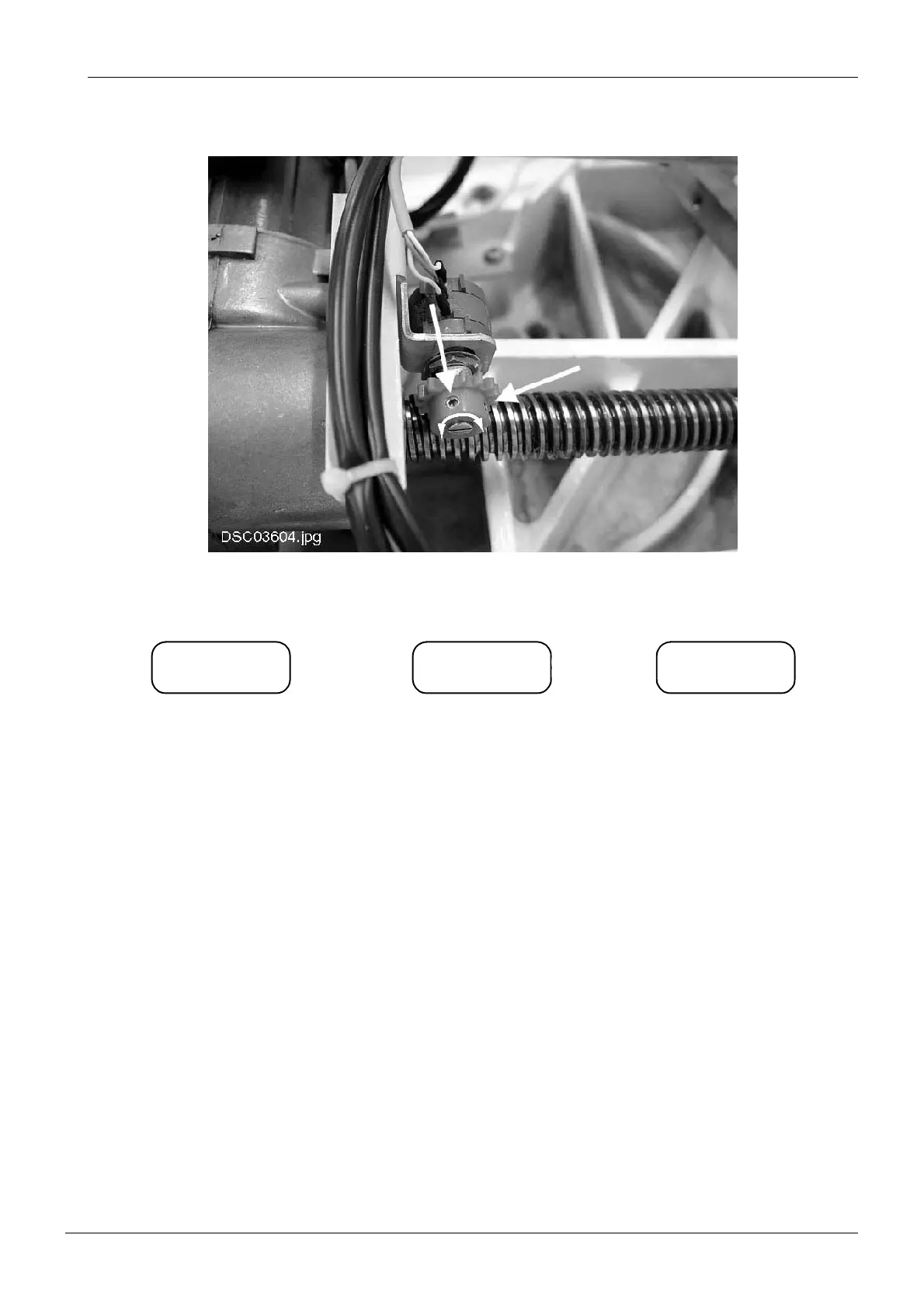

b –_ b –b – –

The sensor presumes the back-

rest to be at a too low position.

Rotate the sensor axle counter

clockwise (seen from the axle).

The sensor presumes the back-

rest to be at a too high position.

Rotate the sensor axle clockwise

(seen from the axle).

The backrest position sen-

sor is calibrated correctly.

–

Loading...

Loading...